Sizing agent for carbon fiber

A technology of sizing agent and curing agent, which is applied in the directions of carbon fiber, fiber processing, textile and paper making, etc., can solve the problems such as the decline of carbon fiber tow bundle and the negative impact on the interface of composite materials.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Stir 80 grams of bisphenol A type epoxy resin E-31, 10 grams of fatty alcohol polyoxyethylene ether AE07 and 10 grams of polyethylene glycol with a molecular weight of 400 at 55°C with a high-speed mixer, slowly add water during the stirring process, and pass After emulsification by phase inversion method, an emulsion with a solid content of about 40% by mass is finally obtained, and this emulsion is denoted as A.

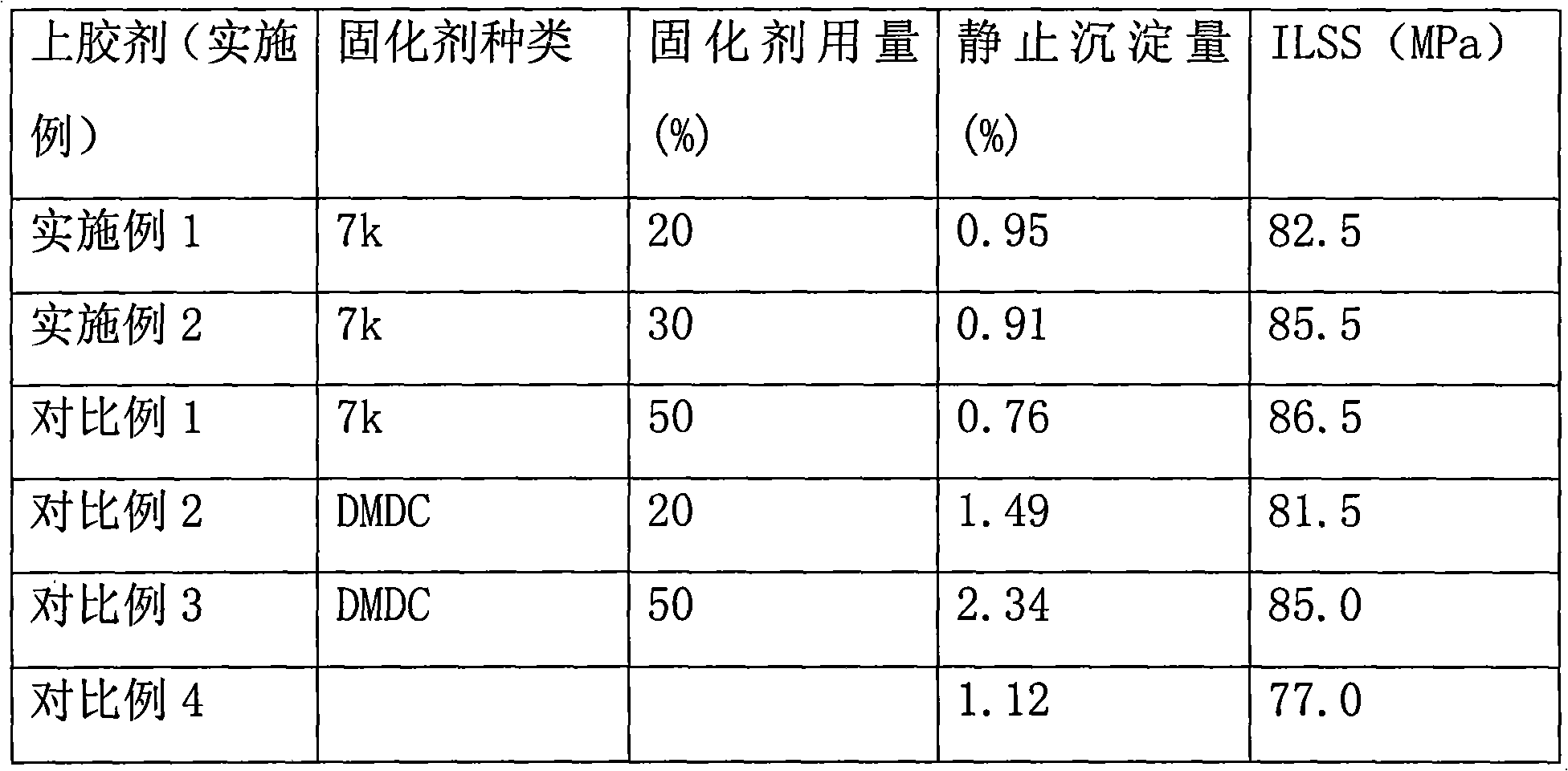

[0026] Dilute A to 5% by mass, add 20% of the theoretical dosage of 7k type water-based curing agent (adduct of epoxy resin amine curing agent and epoxy resin, produced by Beijing Terigu Co., Ltd.), to obtain sizing agent B, carry out the emulsion stability test, the results are shown in Table 1. Then carry out gluing and testing, the method is as follows.

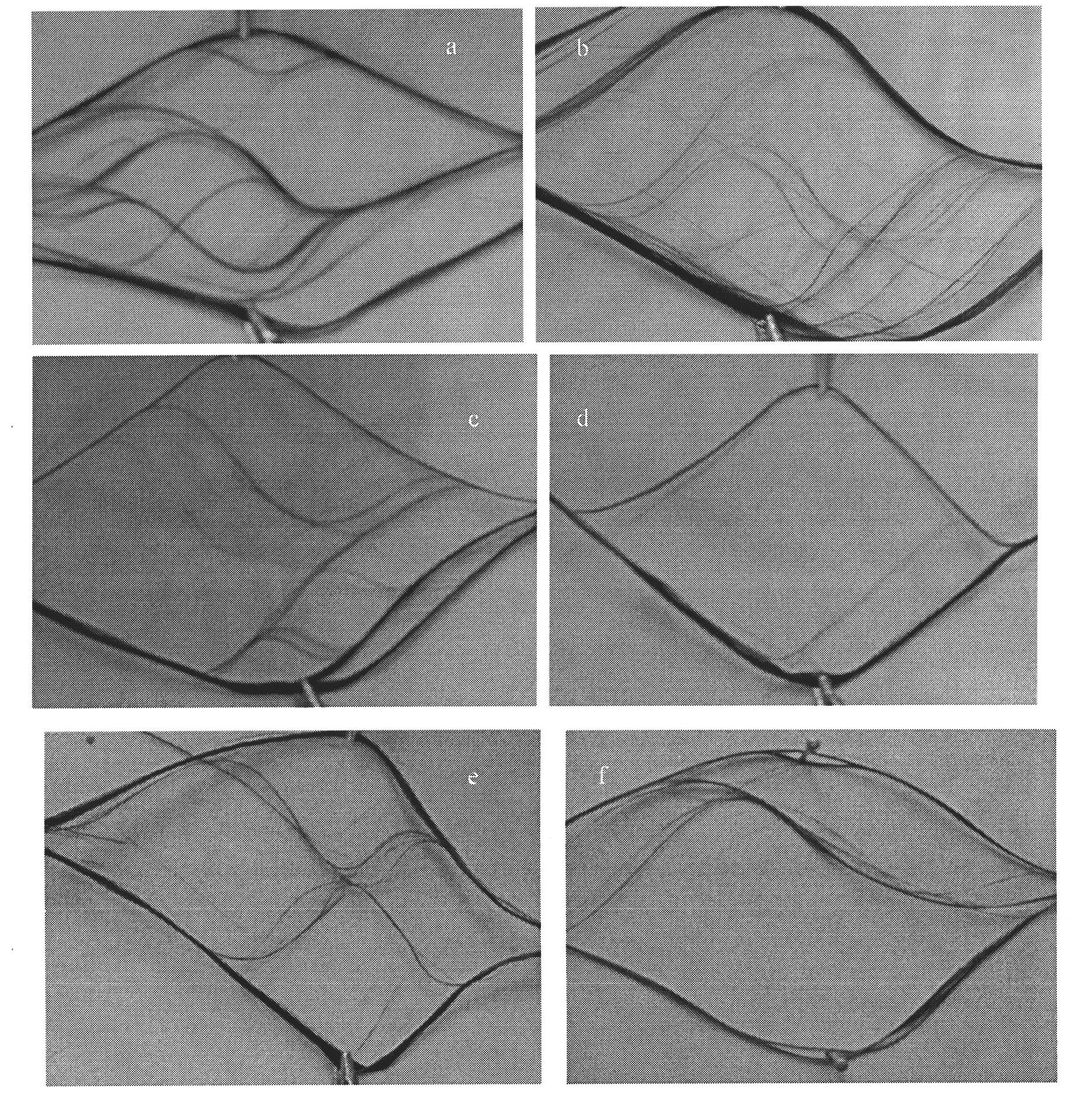

[0027] The 3K, PAN-based carbon fibers obtained by heat treatment at 2500°C were washed with acetone to remove the original sizing agent, and then glued with sizing agent B, and then tested for clusteri...

Embodiment 2

[0029] Dilute the epoxy resin emulsion A to 5% by mass, add 30% of the theoretical amount of 7K water-based curing agent to obtain sizing agent C, and the others are the same as in Example 1. The test results are shown in Table 1 and figure 1 Example 2 in.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com