Cross-linking agent, preparation method and application thereof

A technology of cross-linking agent and silane coupling agent, which is used in chemical instruments and methods, earth-moving drilling, wellbore/well components, etc., to achieve the effect of increasing cross-linking points, wide source of raw materials and strong temperature resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] The present embodiment provides a kind of preparation method of crosslinking agent, comprises the following steps:

[0049] 1. Add 3.4g of cetyltrimethylammonium chloride into 100ml of sodium metaaluminate solution with a mass concentration of 40%, and stir at 60°C for 20min to form a homogeneous solution A.

[0050] 2. Add 5.6g of cetyltrimethylammonium chloride into 25ml of 30% hydrogen peroxide solution, and stir at 60°C for 20min to form a homogeneous solution B.

[0051] 3. Add 20ml of solution B dropwise to 90ml of stirring solution A at a rate of 2ml / min. After the addition is complete, let stand for reaction for 24 hours to obtain the reacted system.

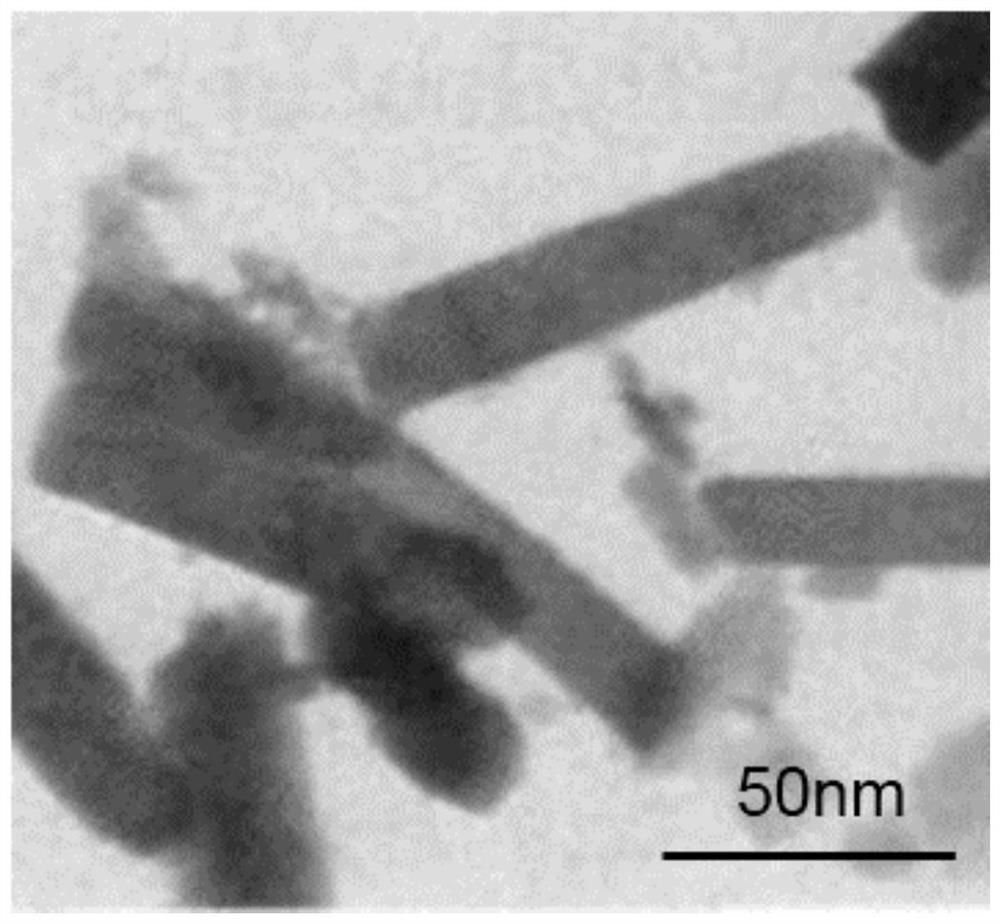

[0052]4. Filter the reacted system, wash the precipitate with deionized water for 5 times, then dry the precipitate in a constant temperature drying oven at 120°C for 10 hours, then place it in a muffle furnace and calcinate at 600°C for 2.5 hours to obtain nanorod-shaped oxide aluminum.

[0053] 5. Taking the t...

Embodiment 2

[0062] The present embodiment provides a kind of preparation method of crosslinking agent, comprises the following steps:

[0063] 1. Add 4.5g of cetyltrimethylammonium bromide into 100ml of sodium metaaluminate solution with a mass concentration of 46%, and stir at 70°C for 10min to form a homogeneous solution A.

[0064] 2. Add 5 g of cetyltrimethylammonium chloride into 18 ml of 30% hydrogen peroxide solution, and stir at 60° C. for 10 min to form a homogeneous solution B.

[0065] 3. Add 16ml of solution B dropwise to 90ml of solution A under stirring at a rate of 3ml / min. After the addition is complete, let stand for reaction for 28 hours to obtain the reacted system.

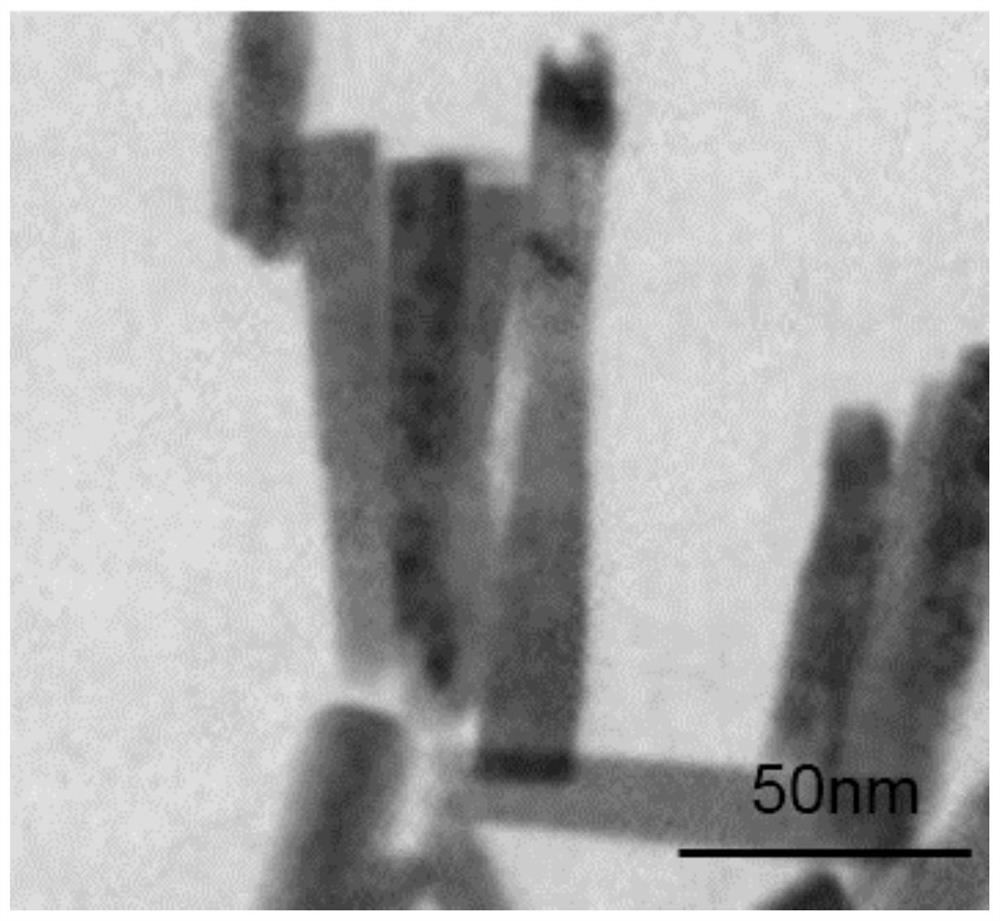

[0066] 4. Filter the system after the reaction in step 3, wash the precipitate with deionized water for 3 times, then dry the precipitate in a constant temperature drying oven at 100°C for 12h, then place it in a muffle furnace and calcinate at 700°C for 1.5h to obtain Nanorod alumina.

[0067] 5. Taking...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com