Cross-linkable ethylene-tetrafluoroethylene copolymer and synthetic method thereof

A tetrafluoroethylene copolymer and tetrafluoroethylene technology are applied in the field of cross-linkable ethylene-tetrafluoroethylene copolymer and its synthesis, which can solve the problems of thermal stability, chemical stability and mechanical properties of the polymer. The effect of high radiation resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

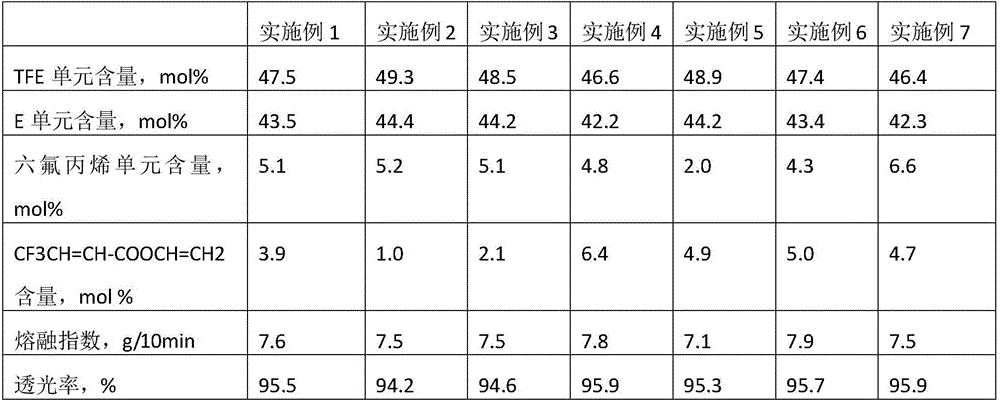

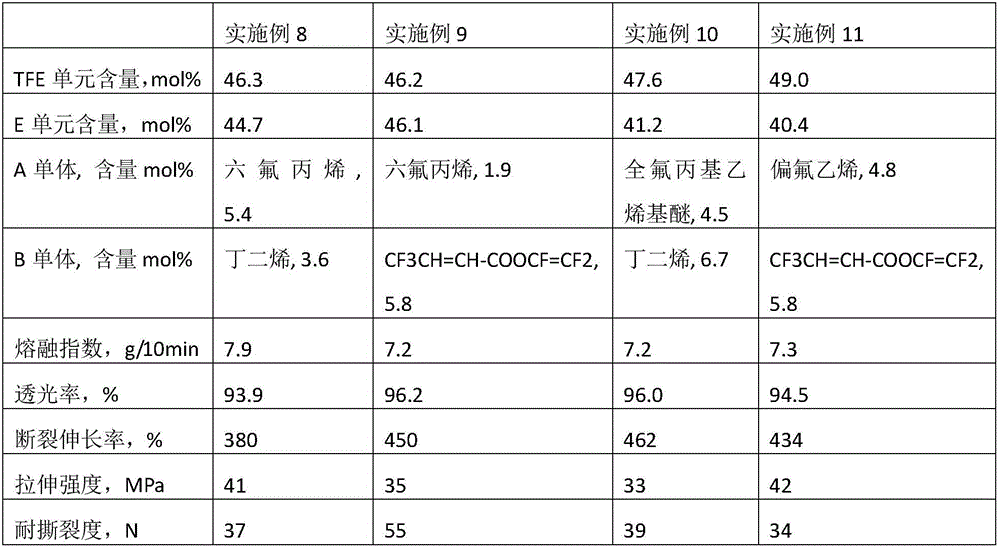

[0033] The present invention is specifically illustrated by the following examples, but the present invention is not limited to these examples.

[0034] The composition ratio of each monomer unit in the polymkeric substance prepared by embodiment is passed F 19 -NMR and IR analysis and calculation.

[0035] The melt index is measured by a melt index meter, and the test standard is ASTM-D1238 (297°C*49N).

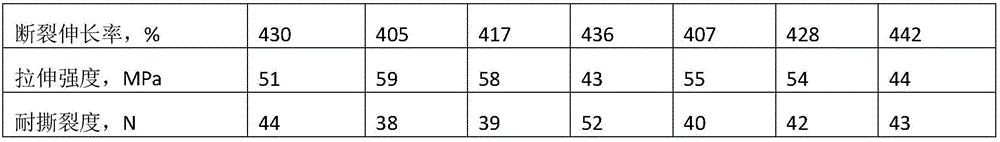

[0036] Add dicumyl peroxide with 2% content of polymer volume ratio, use brabender torque rheometer internal mixer to blend, use flat vulcanizer and dumbbell cutter to prepare standard sample, adopt ASTM D 638 standard The elongation at break and the tensile strength were measured.

[0037] Light transmittance, the polymer is tested by GBT2410-2008 method.

[0038] Tear resistance test: Under the condition of 300°C, extrude the polymer to form a 100μm thick film, according to the method of GB / T16578.9-2009, use the Elemendorf type testing machine to test.

Embodiment 1

[0040]Pour 3L of deionized water into a 5L stainless steel autoclave; 210g of trifluorotrichloroethane (CFC-113); 20g of 30% ammonium perfluorooctanoate solution; vacuumize the system until the oxygen content is below 10ppm. Add 25g of partial fluorocrotonate vinyl ester CF3CH=CH-COOCH=CH2 and 5.1g of methanol, raise the temperature while stirring, keep the temperature stable at 50°C, and add 25:75:20 molar ratio into the system with a compressor Ethylene\tetrafluoroethylene\hexafluoropropylene mixed gas to maintain a certain solubility of hexafluoropropylene in water until the pressure is 1.5MPa, increase the stirring speed to 350 rpm, and continuously pump 30mL containing The CFC-113 solution of 0.55g tert-butyl peroxypivalate initiates the polymerization reaction, and the mixed gas of ethylene\tetrafluoroethylene\hexafluoropropylene molar ratio is 48:43:5 (polymer ratio) is continuously fed to maintain The pressure is 1.2MPa to make the reaction continue. When the amount of...

Embodiment 2~4

[0042] As described in Example 1, the difference is that different amounts of CF3CH=CH-COOCH=CH2 were added, and the resulting polymer was analyzed. The relevant test results are listed in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com