Preparation method of silane coupling agent containing allyl sulfydryl and amino and usage thereof

An allyl mercapto, silane coupling agent technology, applied in chemical instruments and methods, adhesive additives, non-polymer adhesive additives, etc., can solve the problem of damage to surface hardness, wear resistance, scratch resistance, Problems such as prolonging the time of radiation curing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

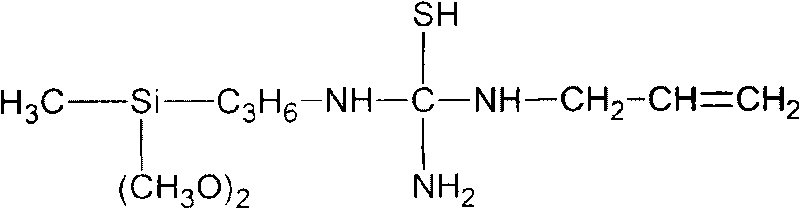

[0047] Add 1, 1.5 and 2 moles of allylthiourea to 1 mole (MeO) 2 CH 3 SiC 3 h 6 NH 2 (trade mark is DB-912) to react, and the reaction formula is as follows.

[0048] The product is called 9S for short, and the excess allyl mercaptan will continue to react with the product to generate an active monomer containing two allyl groups.

[0049]

[0050] or a mixture of both.

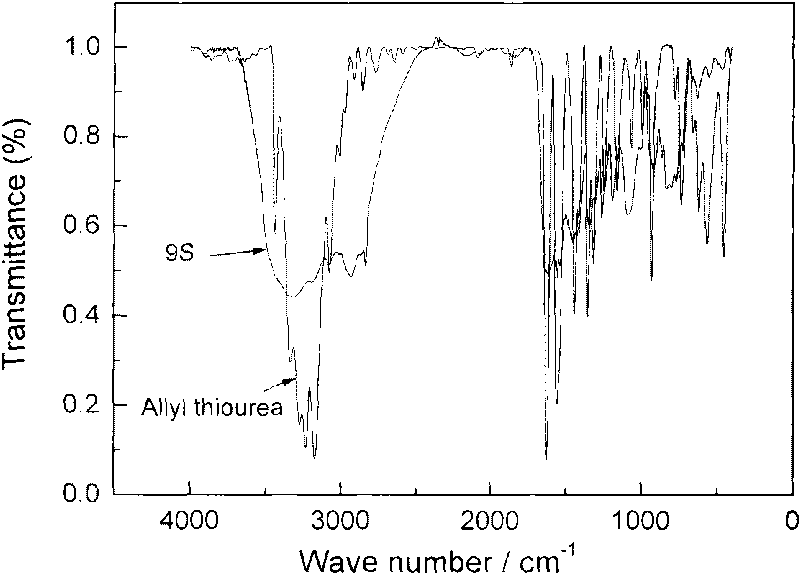

[0051] The infrared spectrum of allylthiourea and 9S is shown in figure 1 . It is reported in the currently available literature that the absorption of the generated thiol S-H is very weak, and it is difficult to see it in slightly long-chain compounds. Therefore, it can only be judged whether it is the target product by the disappearance of the C=S bond. 735~1624cm on the map of allylthiourea -1 The several peaks in between are attributed to the vibration of the interaction between the C=S stretching vibration and the C-N stretching vibration. In this area, 9S basically has no absorption peak, a...

Embodiment 2

[0056] Add 1, 1.5 and 2 moles of allylthiourea to 1 mole (MeO) 3 SiC 3 h 6 NHC 2 h 4 NH 2 (commercial brand is 792) and reacts, and reaction formula is as follows:

[0057]

[0058] or a mixture of both.

[0059] The product is referred to as 7S, and the excess allyl mercaptan will continue to react with the product to generate an active monomer containing two allyl groups.

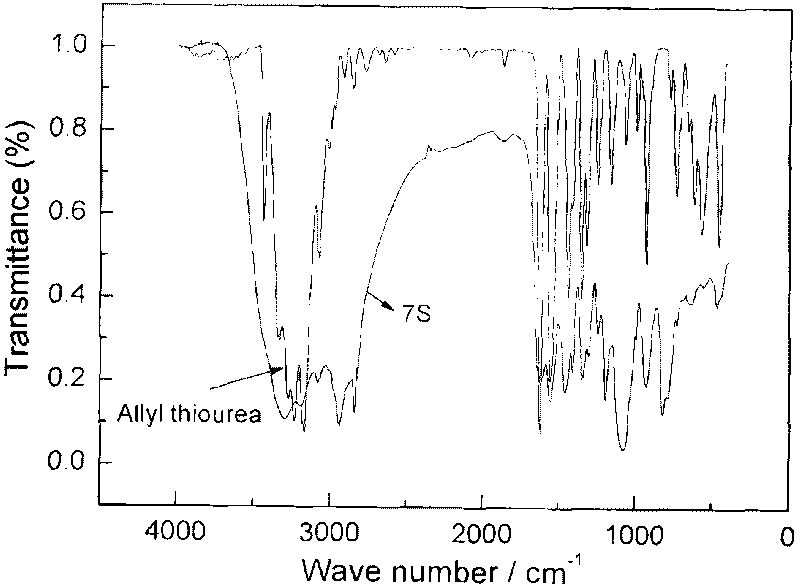

[0060] The infrared spectrum of 7S and allyl mercaptan is shown in figure 2 . with on Figure 1 In the same way, whether it is the target product can be judged by the disappearance of the C=S bond. 735~1624cm on the map of allylthiourea -1 The several peaks in between are attributed to the vibration of the interaction between the C=S stretching vibration and the C-N stretching vibration. In this region, 7S basically has no absorption peak. On the 7S spectrum, 1089cm -1 The peak at is attributed to Si-OCH 3 vibration absorption. It can be seen that there is no C=S bond on the generated 9...

Embodiment 3

[0066] Mix 60 parts of acryloxy-terminated polydimethylsiloxane, 30 parts of propylene glycol diacrylate (TPGDA), 6 parts of trimethylolpropane triacrylate (TMPTA) and 4 parts of photoinitiator, and stir evenly. The bubbles are released to obtain a UV-curable silicone material. Keep away from light.

[0067] Coat the prepared UV-curable material on a glass sheet, and irradiate it with a 400-watt UV lamp for five minutes at room temperature. The bottom layer can be cured, but the surface layer cannot be cured due to oxygen inhibition, and the surface layer cannot be cured after continuous irradiation for 20 minutes. .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com