Graphene/polypropylene composite powder material for SLS and preparation method

A composite powder, polypropylene technology, applied in the direction of additive processing, etc., can solve the problem of low performance of polypropylene SLS parts, and achieve the effects of good fluidity, high precision, and reduced harmfulness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

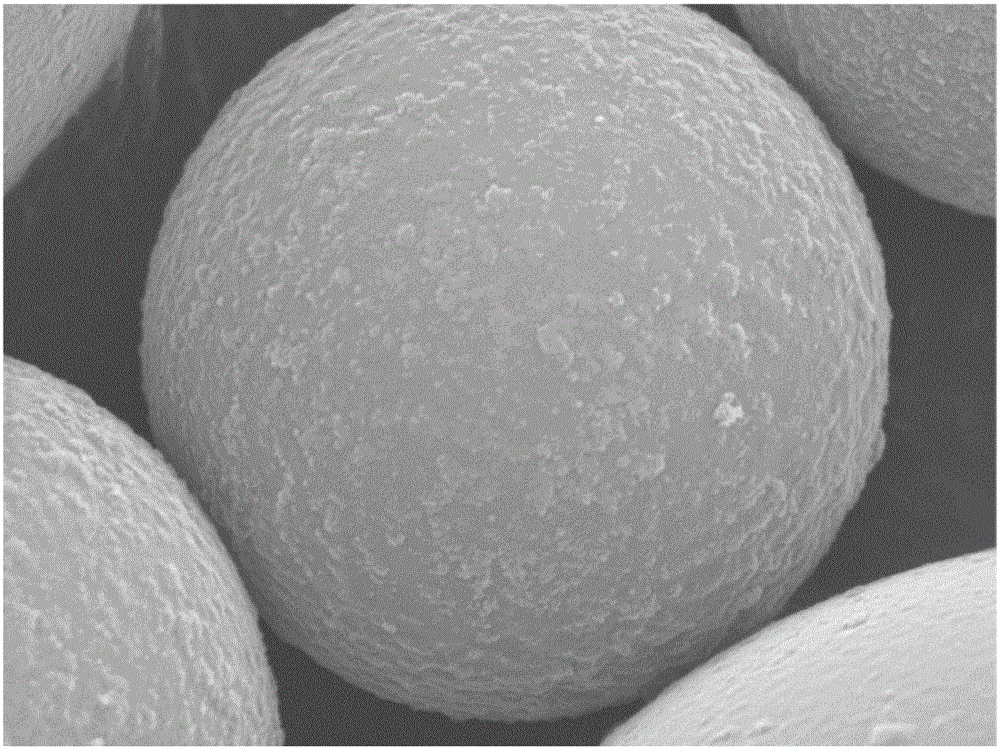

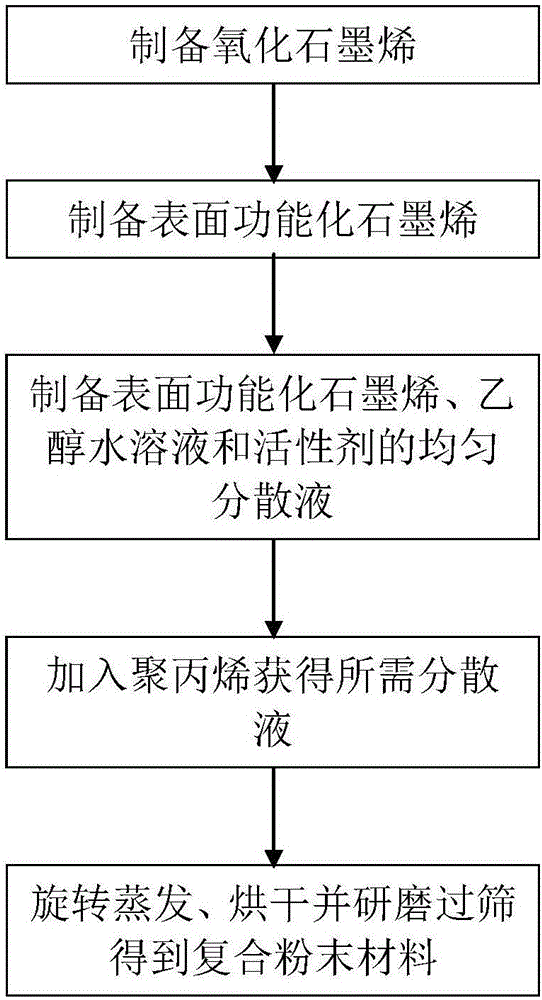

[0030] A method for preparing a graphene / polypropylene nanocomposite powder material for laser selective sintering of the present invention, which uses a surfactant to disperse the graphene in water by ultrasonic treatment, and gradually disperses the PP powder in a small amount while stirring the solution vigorously. Adding it into the solution, heating and volatilizing, and finally pulverizing, drying and sieving the obtained powder aggregates to obtain a composite powder material, which includes the following steps:

[0031] (1) Add graphite flakes into the mixed solution of concentrated sulfuric acid and nitric acid, stir for 16 hours, wash the solution repeatedly with deionized water until neutral, then place the solution at a temperature of 100°C and vacuum-dry it to constant weight. Heat treatment for 15s to obtain expanded graphite, put the expanded graphite into 70vol% ethanol aqueous solution, sonicate at a frequency of 50HZ for 8h, filter and dry in vacuum at 100°C t...

example 1

[0045] Example 1: (graphene mass fraction is the graphene / polypropylene composite powder of 0.5wt%)

[0046] (1) Add 1 g of graphite flakes into the mixed solution of concentrated sulfuric acid and nitric acid, stir for 16 hours, wash the solution repeatedly with deionized water until neutral, then place the solution at a temperature of 100°C to vacuum dry to a constant weight, and at 1050°C Heat treatment for 15s to obtain expanded graphite, put the expanded graphite into 70vol% ethanol aqueous solution, sonicate at a frequency of 50HZ for 8h, filter and vacuum-dry at 100°C to constant weight to obtain the product graphene oxide GO.

[0047] (2) Take out 0.1g of graphene oxide GO obtained in step (1), uniformly disperse in 20vol% ethanol aqueous solution, ultrasonically treat at a frequency of 50HZ and vigorously stir at a speed of 450r / min, with a speed of 4g / s Slowly add 0.4g of γ-aminopropyltriethoxysilane (KH550) to the above solution, keep it at 75°C for 24h, filter it w...

example 2

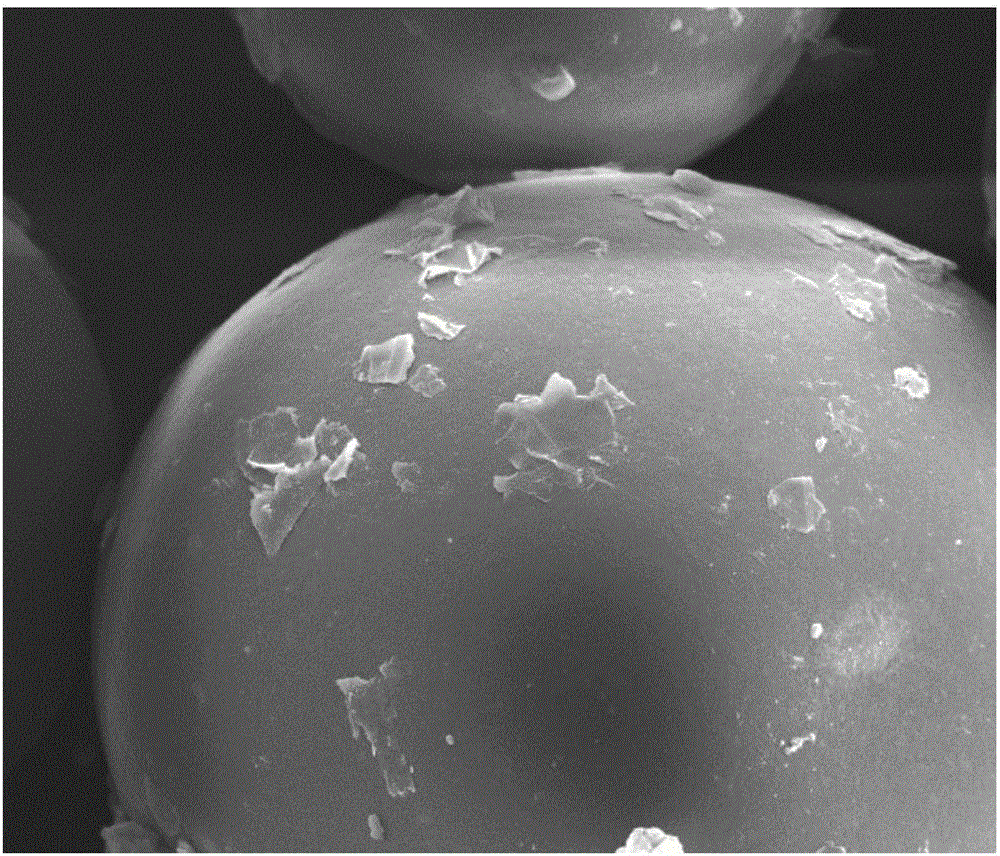

[0051] Example 2: (graphene mass fraction is the graphene / polypropylene composite powder of 6wt%)

[0052] (1) Add 50g of graphite flakes into the mixed solution of concentrated sulfuric acid and nitric acid, stir for 16 hours, wash the solution repeatedly with deionized water until neutral, then place the solution at a temperature of 100°C to vacuum-dry to constant weight, and at 1050°C Heat treatment for 15s to obtain expanded graphite, put the expanded graphite into 70vol% ethanol aqueous solution, sonicate at a frequency of 50HZ for 8h, filter and vacuum-dry at 100°C to constant weight to obtain the product graphene oxide GO.

[0053] (2) Take out 30g of graphene oxide GO obtained in step (1), uniformly disperse in 10vol% ethanol aqueous solution, ultrasonicate at a frequency of 50HZ and vigorously stir at a speed of 300r / min, at a speed of 2g / s Slowly add 120g of N-(β-aminoethyl)-γ-aminopropyltriethoxysilane (KH901) to the above solution, keep at 80°C for 20h, filter with...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com