Hindered-phenol-quaternary-ammonium-salt-modified-imvite-modified PP-R pipe

A technology of quaternary ammonium salt and hindered phenol, which is applied in the field of materials, can solve the problems of not being able to effectively improve the low-temperature toughness, antibacterial and anti-aging properties of PP-R pipes, reduce the mechanical properties of PP-R pipes, and short action time, etc., to achieve excellent Anti-aging performance, good anti-aging performance, effect of improving compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

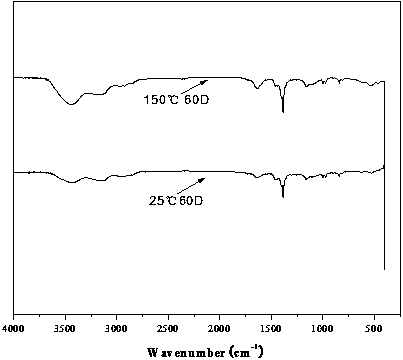

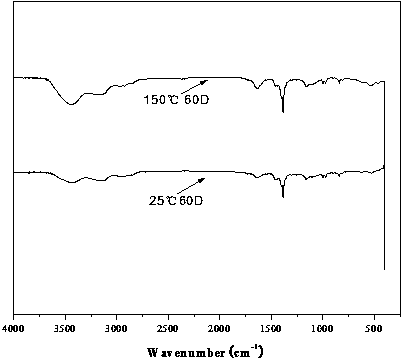

Image

Examples

Embodiment 1

[0033] Example 1 Preparation of Hindered Phenol Quaternary Ammonium Salt Modified Montmorillonite 1

[0034] In N 2 Under protection, add 15 parts of montmorillonite, 60 parts of toluene, 1 part of 2,6-di-tert-butyl-4-methylphenol and 15 parts of hydrochloric acid into a three-necked flask equipped with magnetic stirring, condenser and thermometer. Parts, 15 parts of paraformaldehyde, 1 part of triphenylamine, heated in a water bath at 110°C for 12h, filtered with suction, washed the filter cake with deionized water, washed with 50% ethanol solution to chlorine-free, dried at 100°C, ground 200 mesh Sieve spare.

experiment example 2

[0035] Experimental example 2 Preparation of modified montmorillonite 2 with hindered phenol quaternary ammonium salt

[0036] In N 2 Under protection, add 15 parts of montmorillonite, 60 parts of tetrahydrofuran, 1 part of 2,6-di-tert-butyl-4-methylphenol, and 10 parts of hydrochloric acid into a three-necked flask equipped with magnetic stirring, condenser and thermometer. 10 parts of paraformaldehyde, 1 part of triphenylamine, heated in a water bath at 80°C for 12h, suction filtered, washed the filter cake with deionized water, washed with 50% ethanol solution until no chlorine ions, dried at 100°C, ground 200 mesh Sieve spare.

experiment example 3

[0037] Experimental example 3 Preparation of montmorillonite 3 modified by hindered phenol quaternary ammonium salt

[0038] In N 2 Under protection, add 15 parts of montmorillonite, 60 parts of toluene, 1 part of 2,6-di-tert-butyl-4-methylphenol, and 10 parts of hydrochloric acid into a three-necked flask equipped with magnetic stirring, condenser and thermometer. 10 parts of paraformaldehyde, 1 part of triphenylamine, heated in a 110℃ water bath for 8h, suction filtered, washed the filter cake with deionized water, washed with 50% ethanol solution to no chloride ion, dried at 100℃, ground through a 200 mesh sieve spare.

[0039] Example 1 Hindered phenol quaternary ammonium salt modified montmorillonite modified PPR pipe special material 1

[0040] Mix 100 parts of PP-R, 3 parts of hindered phenol quaternary ammonium salt modified montmorillonite prepared in Experimental Example 1, 6 parts of POE-g-MAH and 3 parts of HDPE-g-MAH, and then add the same direction twin screw The extr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com