Boron nitride heterogeneous filler and preparation method thereof, and fiber-reinforced epoxy resin heat-conducting composite material, preparation method and application thereof

A heat-conducting composite material and epoxy resin technology, applied in the field of composite materials, can solve problems such as restricting the application range of fiber-reinforced epoxy resin composite materials and limited thermal conductivity of composite materials.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

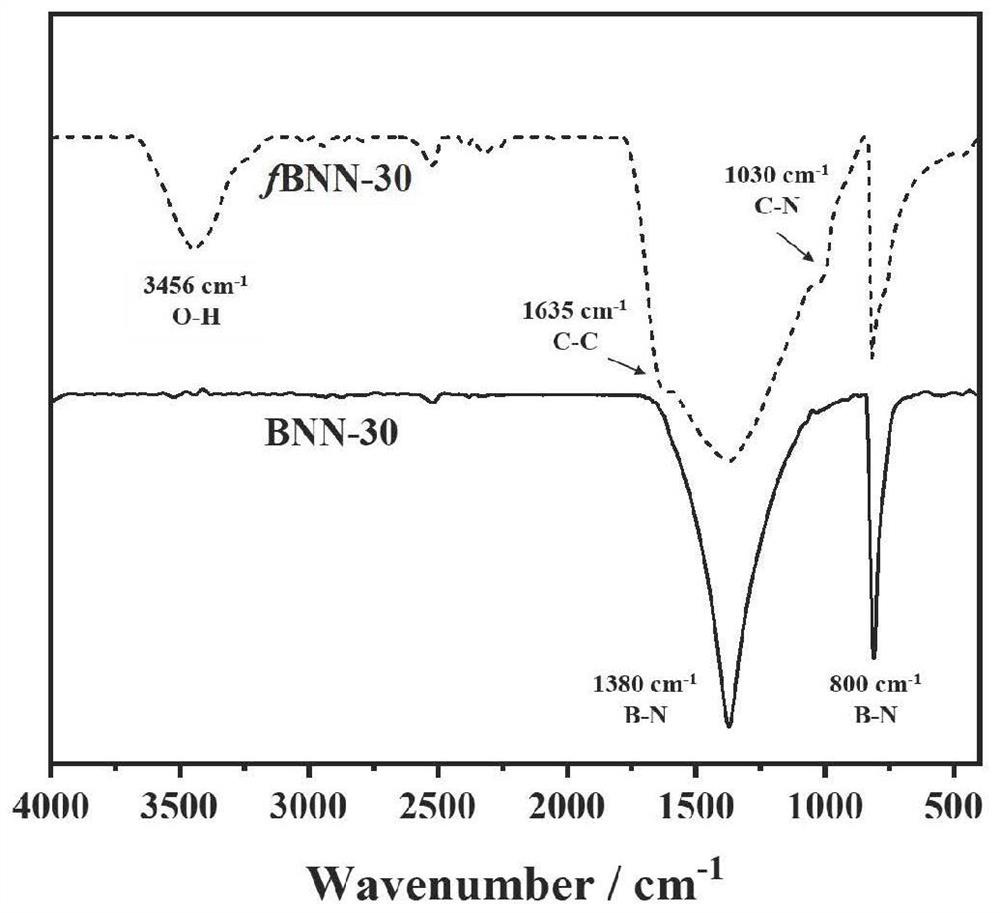

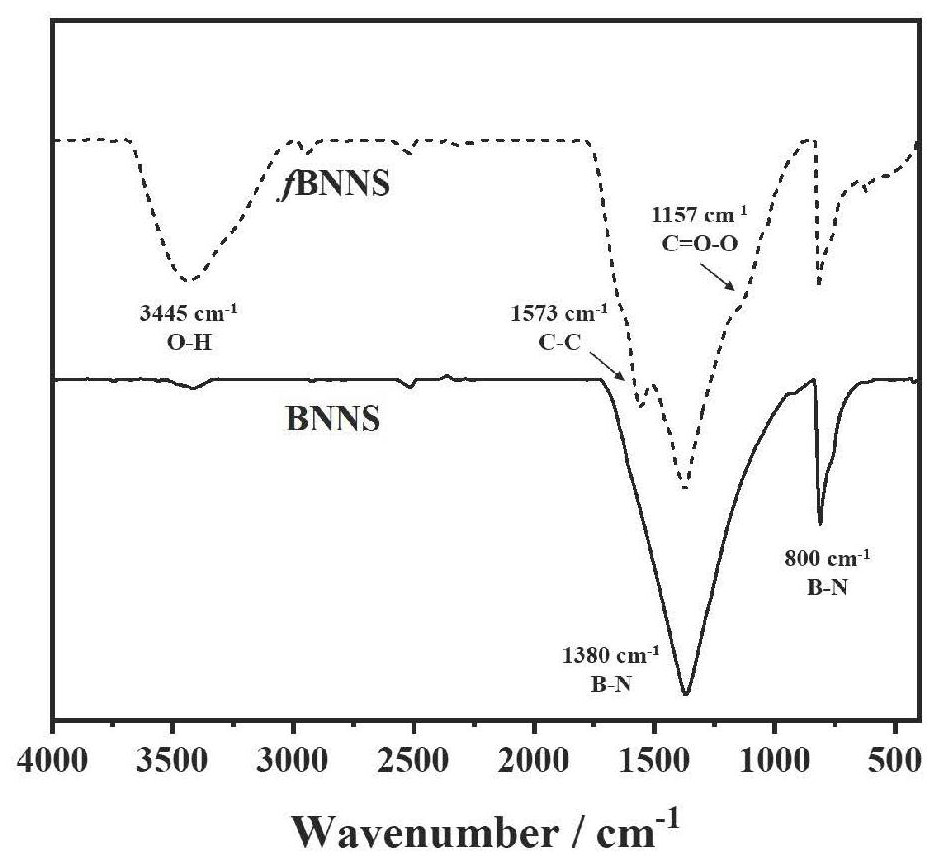

[0056] In the present invention, the preparation method of the modified spherical micron boron nitride or modified boron nitride nanosheets preferably includes the following steps:

[0057] Boron nitride is mixed with an aqueous polymer electrolyte solution for coating reaction;

[0058] The boron nitride is spherical micron boron nitride or boron nitride nanosheets, and the polymer electrolyte is polyanion electrolyte or polycation electrolyte.

[0059] In the present invention, when the modified spherical micron boron nitride is positively charged and the modified boron nitride nanosheet is negatively charged; the preparation method of the positively charged modified spherical micron boron nitride preferably comprises the following steps: The micron boron nitride is mixed with the polycation electrolyte aqueous solution, and the first coating reaction is carried out to obtain the positively charged modified spherical micron boron nitride. In the present invention, the mass ...

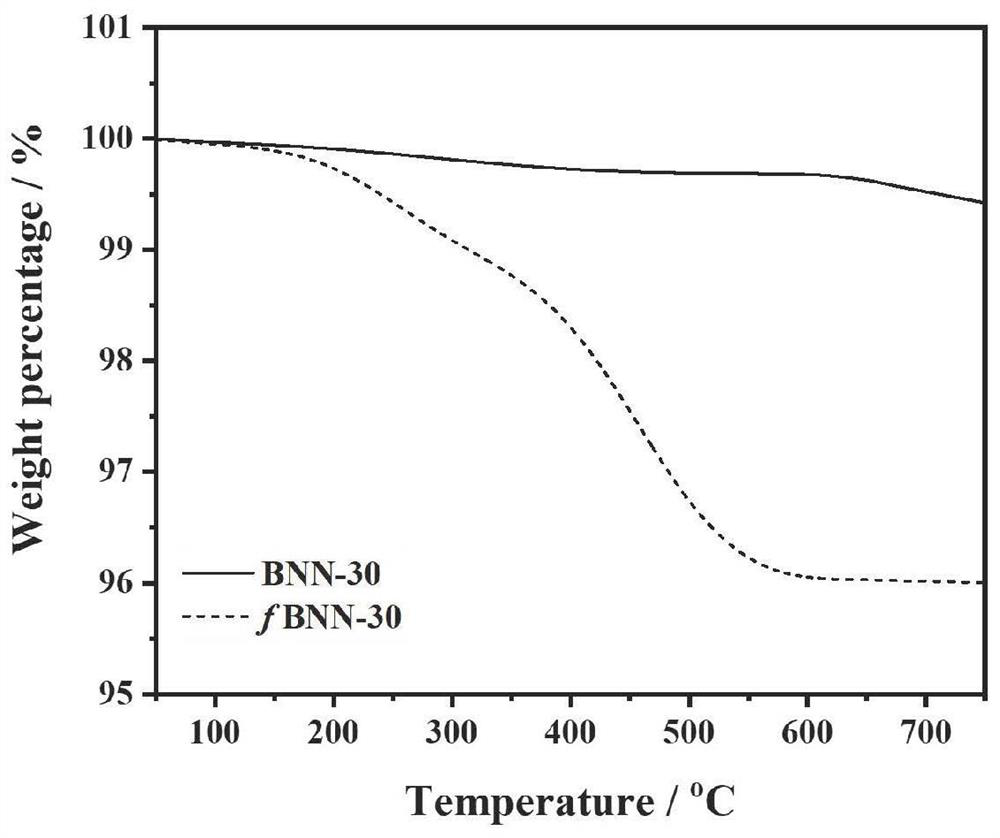

Embodiment 1

[0126] Mix 10 g of spherical micron boron nitride with an average particle size of 30 μm and 500 g of a polydiallyldimethylammonium chloride aqueous solution with a mass concentration of 1.5 wt %, carry out coating reaction at 30° C. for 48 h, and then suction filter (using Washing with deionized water), and drying the filter residue obtained by suction filtration at 55° C. for 12 hours to obtain positively charged modified spherical micron boron nitride;

[0127] 21g of boron nitride nanosheets with an average diameter of 120nm and an average thickness of 20nm and 1400g of a mass concentration of 1.4wt% sodium polyacrylate aqueous solution were mixed, and the coating reaction was carried out at 30°C for 48h, followed by suction filtration (using deionized water to carry out washing), drying the filter residue obtained by suction filtration at 55° C. for 12 hours to obtain negatively charged modified boron nitride nanosheets;

[0128] Sonicate 10 g of modified spherical micron...

Embodiment 2

[0132] 6g of spherical micron boron nitride with an average particle diameter of 30 μm and 320 g of a polydiallyldimethylammonium chloride aqueous solution with a mass concentration of 1.7 wt % were mixed, and the coating reaction was carried out at 32° C. for 47 h, followed by suction filtration (using Washing with deionized water), and drying the filter residue obtained by suction filtration at 57° C. for 12 hours to obtain positively charged modified spherical micron boron nitride;

[0133] 14g of boron nitride nanosheets with an average diameter of 120nm and an average thickness of 20nm and 1000g of a mass concentration of 1.6wt% sodium polyacrylate solution were mixed, and the coating reaction was carried out at 32°C for 47h, followed by suction filtration (using deionized water to carry out washing), drying the filter residue obtained by suction filtration at 56° C. for 12 hours to obtain negatively charged modified boron nitride nanosheets;

[0134] Sonicate 6 g of modi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com