Aramid fiber (AF) surface modification method, product and preparation method of product

A surface modification, aramid fiber technology, applied in textiles and papermaking, light/infrared/X-ray fiber processing, fiber processing, etc., can solve the problems of fast reaction speed, difficult to control, difficult continuous production, and difficult to industrialize production, etc. To achieve the effect of enhanced mechanical bite, increased roughness, and improved surface properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

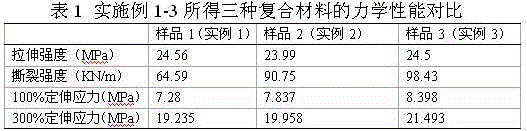

Examples

Embodiment 1

[0011] Embodiment 1 of the present invention: a method for surface modification of aramid fibers, placing aramid fiber bundles in a beaker, soaking them in acetone, cleaning them in an ultrasonic cleaner for 4 hours, removing impurities attached to the surface, and then heating them at 80°C After drying, the aramid fibers are cut into 5mm long short fibers, sealed for later use.

[0012] Add 3 parts of aramid fiber and 50 parts of natural rubber into a rubber-plastic internal mixer (XSM-05, Shanghai Kechuang Rubber and Plastic Machinery Equipment Co., Ltd.) to make a master batch; then add 50 parts of natural rubber, master batch, 5 parts of zinc oxide, 4 parts of stearic acid, 1.5 parts of anti-aging agent 4020, 0.5 part of accelerator D, 2.21 parts of accelerator M, 1.97 parts of accelerator DM, 0.33 parts of accelerator TMTD and 1.71 parts of sulfur vulcanizing agent, add double Knead in a roller mill, knead for 10 minutes, and leave the sheet for 24 hours to eliminate inte...

Embodiment 2

[0013] Embodiment 2 of the present invention: a method for surface modification of aramid fibers, placing aramid fiber bundles in a beaker, soaking them in acetone, cleaning them in an ultrasonic cleaner for 4 hours, removing impurities attached to the surface, and then heating them at 80°C Drying, laying the dried aramid fibers into a layer, using a UV lamp with a wavelength of 264nm and a power of 800W to irradiate at a distance of 20cm from the aramid fiber, under normal temperature and pressure conditions, the radiation time is 4 minutes, and then cut the aramid fiber into short fibers with a length of 5 mm to obtain a modified aramid fiber, which is sealed for later use.

[0014] Add 3 parts of modified aramid fiber and 50 parts of natural rubber into a rubber-plastic internal mixer (XSM-05, Shanghai Kechuang Rubber and Plastic Machinery Equipment Co., Ltd.) to make a master batch; then add 50 parts of natural rubber, master batch , 5 parts of zinc oxide, 4 parts of stear...

Embodiment 3

[0015] Embodiment 3 of the present invention: the surface modification method of aramid fiber, place the aramid fiber bundle in a beaker, soak it with acetone, put it in an ultrasonic cleaner for cleaning for 4 hours, remove the impurities attached to its surface, and then heat it at 80°C Drying, laying the dried aramid fibers into a layer, using a UV lamp with a wavelength of 264nm and a power of 1000W, irradiating at a distance of 20cm from the aramid fiber, under normal temperature and pressure conditions, the radiation time is 8 minutes, and then cut the aramid fibers into short fibers with a length of 5 mm to obtain modified aramid fibers, which are sealed for later use.

[0016] Add 3 parts of modified aramid fiber and 50 parts of natural rubber into a rubber-plastic internal mixer (XSM-05, Shanghai Kechuang Rubber and Plastic Machinery Equipment Co., Ltd.) to make a master batch; then add 50 parts of natural rubber, master batch , 5 parts of zinc oxide, 4 parts of stear...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com