Patents

Literature

44results about How to "High speed dispersion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Aqueous cold pigment double-coat multifunctional thermal-insulation external wall paint and preparation method thereof

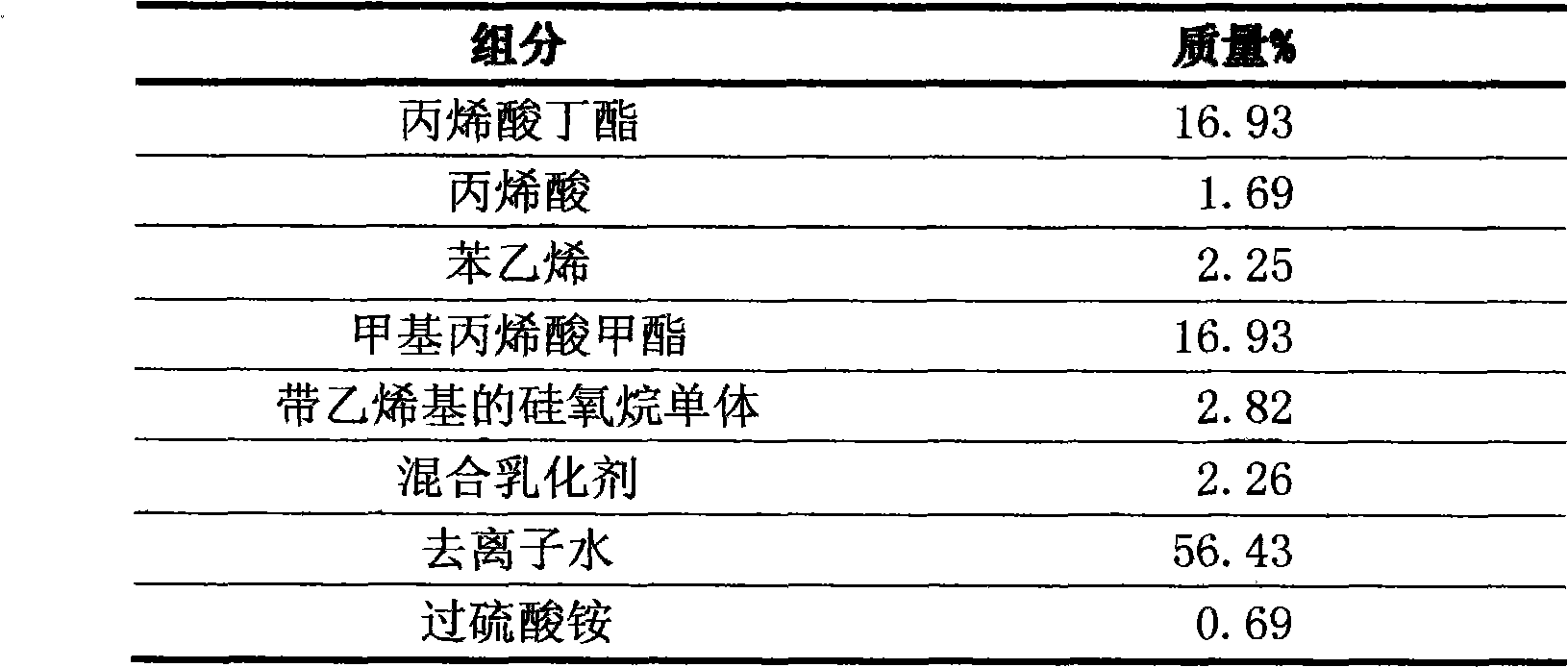

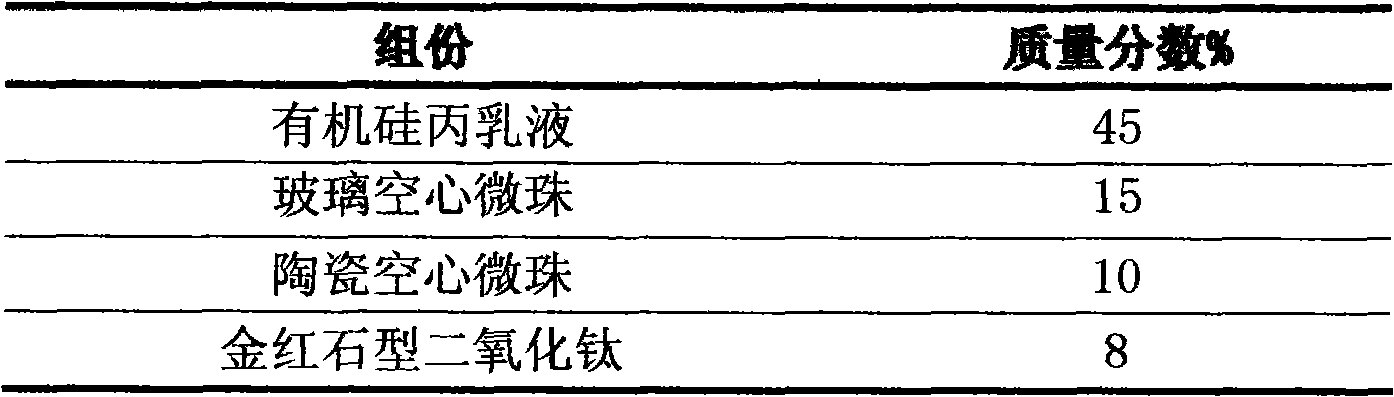

The invention discloses an aqueous cold pigment double-coat multifunctional thermal-insulation external wall paint and a preparation method thereof. The invention belongs to the field of paint, and relates to an external wall paint based on an aqueous organic silicone-acrylate emulsion, particularly a thermal-insulation external wall paint. The invention provides an aqueous cold pigment double-coat multifunctional thermal-insulation external wall paint. The paint is composed of a top-coat component and an intermidiate-coat component, wherein the top-coat component comprises aqueous organic silicone-acrylate emulsion, cold pigment, glass hollow microspheres, ceramic hollow microspheres, rutile type titanium dioxide, nano infrared emission ceramic powder, superfine French chalk, infrared emission ceramic powder, accessory ingredients and water. In the painting process, the top-coat and intermediate coat are used separately and respectively form a film. The paint can perform the functions of self cleaning and thermal insulation, thereby achieving the goals of energy saving, consumption reduction and environment protection.

Owner:刘立新

Water-resistant high-temperature-resistant single-component waterborne polyurethane adhesive and preparation method thereof

InactiveCN108342181AHigh strengthImprove heat resistanceNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesPolyesterPolyurethane adhesive

The invention discloses a water-resistant high-temperature-resistant single-component waterborne polyurethane adhesive and a preparation method thereof and relates to the technical field of polyurethane adhesives. The adhesive comprises, by weight, 30-40 parts of polytetrahydrofuran glycol, 15-22 parts of polycarbonate diol, 3-7 parts of poly-2,6-polyethylene naphthalate polyester glycol, 17-25 parts of diisocyanate, 2-5 parts of chain extender, 0.5-2 parts of silane coupling agent modified silicon dioxide nanoparticles, 0.1-0.6 part of dibutyltin dilaurate, 4-8 parts of acetone, 1-3 parts oftriethylamine, 0.05-0.1 part of sodium hydroxide and an appropriate amount of water. Polytetrahydrofuran and polycarbonate diol are adopted as oligomer polyhydric alcohols in raw materials for preparing polyurethane, and added poly-2,6-polyethylene naphthalate polyester glycol is introduced to a soft-segment part of polyurethane; by adding silane coupling agent modified silicon dioxide nanoparticles, the mechanical properties and heat resistance of the adhesive can be improved; the prepared adhesive is high in adhesive force and excellent in water resistance and high temperature resistance, and the application range of the adhesive is enlarged.

Owner:佛山市三水日邦化工有限公司

High-thermal conductivity flame-retardant epoxy resin pouring sealant and preparation method thereof

InactiveCN107779153AFlame retardantGood dispersionNon-macromolecular adhesive additivesMacromolecular adhesive additivesEpoxyBoron nitride

The invention discloses a high-thermal conductivity flame-retardant epoxy resin pouring sealant. The heat conductivity coefficient of the pouring sealant reaches 3.0W / mK-5.0W / mK, and the flame-retardant grade is UL94 V-0. The pouring sealant contains a component A and a component B, wherein the component A is mainly prepared from epoxy resin, an inorganic fillings, a dispersing agent, a defoamingagent and an active diluent; the component B is mainly prepared from a curing agent and an accelerant; the inorganic fillings are selected from at least two of boron nitride nanotubes, boron nitride nanosheets, aluminum nitride, aluminum oxide and silica powder; and the mass ratio of the component A to the component B is (10-15) to 1. The invention further discloses a preparation method of the epoxy resin pouring sealant. The heat conductivity coefficient of the pouring sealant reaches 3.0W / mK-5.0W / mK, and the flame-retardant grade is UL94 V-0.

Owner:ZHUZHOU TIMES ELECTRIC INSULATION

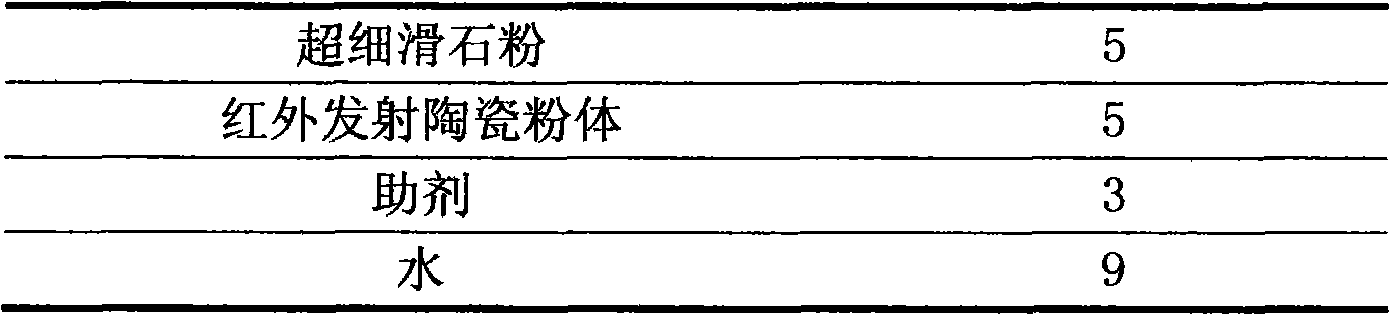

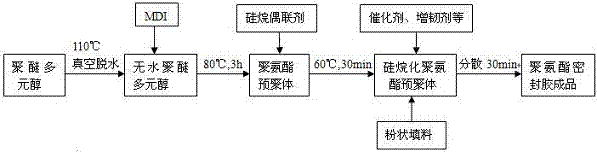

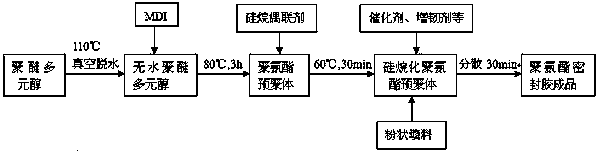

One-component high-elasticity silylated polyurethane waterproof coating and production method thereof

ActiveCN107286835AHigh speed dispersionImprove performancePolyurea/polyurethane coatingsChemistrySilane coupling

The invention discloses a one-component high-elasticity silylated polyurethane waterproof coating and a production method of the one-component high-elasticity silylated polyurethane waterproof coating. The one-component high-elasticity silylated polyurethane waterproof coating is prepared from 50 to 70 parts of polyether polyol 330N, 180 to 200 polyether polyol DL-2000, 60 to 70 parts of diphenylmethane diisocyanate, 10 to 20 parts of toughening agent heavy-vacuum gas oil, 10 to 15 parts of a silane coupling agent, 0.3 to 0.5 part of a catalyst, 3 to 5 parts of a latent curing agent, 5 to 7 parts of epoxy resin, 20 to 30 parts of a non-reactive diluent, 140 to 180 parts of a powder filler, 3 to 5 parts of white carbon black, 3 to 5 parts of carbon black, and 0.3 part of an antioxidant. The one-component high-elasticity silylated polyurethane waterproof coating disclosed by the invention has the advantages of overcoming weaknesses of foaming, being more friendly to the environment, further lowering the production cost, facilitating popularization and application, prolonging the shelf life, shortening the curing time, improving the product quality, having better performances, especially bond performances, not requiring on-site measurement and blending for being a single component, thereby being more convenient and fast in construction.

Owner:XINJIANG KENENG WATERPROOF & PROTECTION TECH CO LTD

Epoxy anti-corrosive paint for underwater construction and preparation method

InactiveCN101311233AInternal cohesionGuaranteed internal adhesionAntifouling/underwater paintsPaints with biocidesSolvent freeSolvent

The invention relates to a smearing epoxy anti-corrosion coating for underwater concrete and steel structure and the preparation thereof, comprising the blending of component A and component B. The invention is characterized in that the Component A consists of 20-40wt percent of solvent-free epoxide resin, 0-6wt percent of glycidyl ether epoxy active diluent, 13-50wt percent of barite powder, 0-30wt percent of titanium pigment, 0.5-2wt percent of modified polyamide thixotropic agent, 0.2-0.5wt percent of dispersant, 0.2-0.5wt percent of defoamer and 1-4wt percent of resin acceptor; the preparation viscosity is 40000-120000cP and the proportion is 1.5-2.5. The component B consists of 10-30wt percent of C5-C20 hydrocarbon chain Mannich di-benzene-ring epoxy curing agent, 2-10 percent of reacton typed promoter, 2, 4, 6-tri-dialkyl amine alkylamine methyl phenol. The coating of the invention has the advantages of strong adhesive attraction at the initial stage, excellent initial adhesive attraction under dynamic water, quick solidification in underwater construction and no drain and spalling, and can resist the impact of water with the speed of 1m per second, realize initial set in an hour to reach 30-50 percent of the design strength and reach more than 1MPa of bond strength in 24 hours, thereby overcoming the disadvantage of difficult coating under dynamic water of the existing epoxy coating.

Owner:无锡市南雅化工有限公司

Anhydrous stemming and preparation method thereof

The invention provides an anhydrous stemming and a preparation method thereof. The anhydrous stemming is composed of the following raw materials: 15 to 25 % of corundum aggregate, 10 to 20 % of corundum powder, 10 to 15 % of redstone, 10 to 15 % of silicon carbide, 0 to 8 % of silicon nitride iron, 12 to 16 % of plastic clay, 13 to 18 % of coke powder, 4 to 8 % of high-temperature asphalt, 1 to 2 % of applied borax or boric acid and 14 to 20 % of applied tar. The preparation method is characterized by using a production apparatus such as a powerful mixer, and comprising steps of: blending the above raw materials, dry-mixing in the mixer for 1 to 2 minutes, adding 80 to 90 % of the tar with stirring, finely adjusting an adding amount of the tar in accordance with the stemming situation after stirring for 2 to 10 minutes, continuously stirring for 15 to 30 minutes, and molding with compression by using an extruder. The stemming provided by the invention has good performances of rapid sintering and high temperature, shrinks relatively small after being burnt, and can greatly reduce adverse phenomena of large mud, broken iron notch, long-time splashing, rapid hole reaming, etc. A new production technology is employed to ensure long-term stability of product quality, and thus the stemming has good workability and using performance.

Owner:CENT RES INST OF BUILDING & CONSTR CO LTD MCC GRP +1

Method for producing controllable-particle-size calcium carbonate by continuous carbonization

ActiveCN106976898AImprove the carbonization effectHigh speed dispersionCalcium/strontium/barium carbonatesCalcium hydroxideDispersity

The invention discloses a method for producing controllable-particle-size calcium carbonate by continuous carbonization. A water ring air compressor, a primary carbonization tower, a gas distributor, a primary carbonization stirring device, a gas storage tank, a secondary carbonization tower, a secondary carbonization stirring device, a circulating emulsification pump, a calcium hydroxide storage tank, a venturi ejector and the like are applied. The method includes specific operation steps of primary carbonization, circulating emulsification, CO2 gas suction, calcium hydroxide slurry feeding and secondary circulating carbonization. The particle size of calcium carbonate prepared according to the method can be controlled in a range of 80-200nm, and a product is uniform in crystalline form, regularly cubic in morphology, small in agglomerated particle quantity, high in dispersity, narrow in particle size distribution and low in oil absorption value.

Owner:FUJIAN HONGFENG NANO TECH

Epoxy polyurethane zinc phosphor antiseptic paint and preparation thereof

InactiveCN101343500AImprove adhesionFast dryingAnti-corrosive paintsEpoxy resin coatingsEpoxyFoaming agent

The invention provides an epoxy polyurethane zinc phosphorus anti-corrosive paint, the components of the anti-corrosive paint are as follows: a first component which comprises aliphatics solidifying agent and environmental protective solvent, a second component which comprises macromolecular epoxy resin, anti-corrosive pigment I, anti-corrosive painting II, the environmental protective solvent, dispersing agent, anti-foaming agent, leveling agent and filler. When the the first component and the second component are used, the mixed ratio of the weight of the first component and the second component is 1:5. The invention also discloses a preparation method of the epoxy polyurethane zinc phosphorus anti-corrosive paint. The epoxy polyurethane zinc phosphorus anti-corrosive paint has the advantages that the epoxy polyurethane zinc phosphorus anti-corrosive paint of the invention adopts macromolecular epoxy resin and adipose polyisocyanate reaction, the adhesive force of the paint film is good, the drying speed is quick, and the thermal-resistant temperature of the paint reaches over 150 DEG C, because the tetroxy chromate and xinc phosphate compound anti-corrosive high-efficient pigment are adopted, the anti-corrosive paint has the long-time anti-corrosive performance; the surface treatment of the backing material is not required strictly, the construction is convenient, and the environmental protective solvent can not cause pollution to the environment; the paint film has good acid resistance and alkali resistance and solvent resistance; the preparation method is simple, and the large-scale production is easy.

Owner:WUXI HUHUANG PAINT

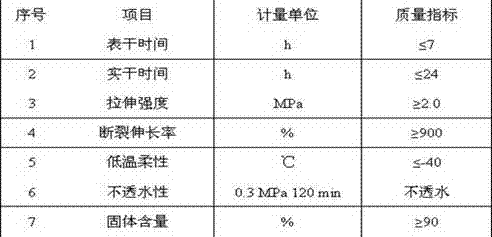

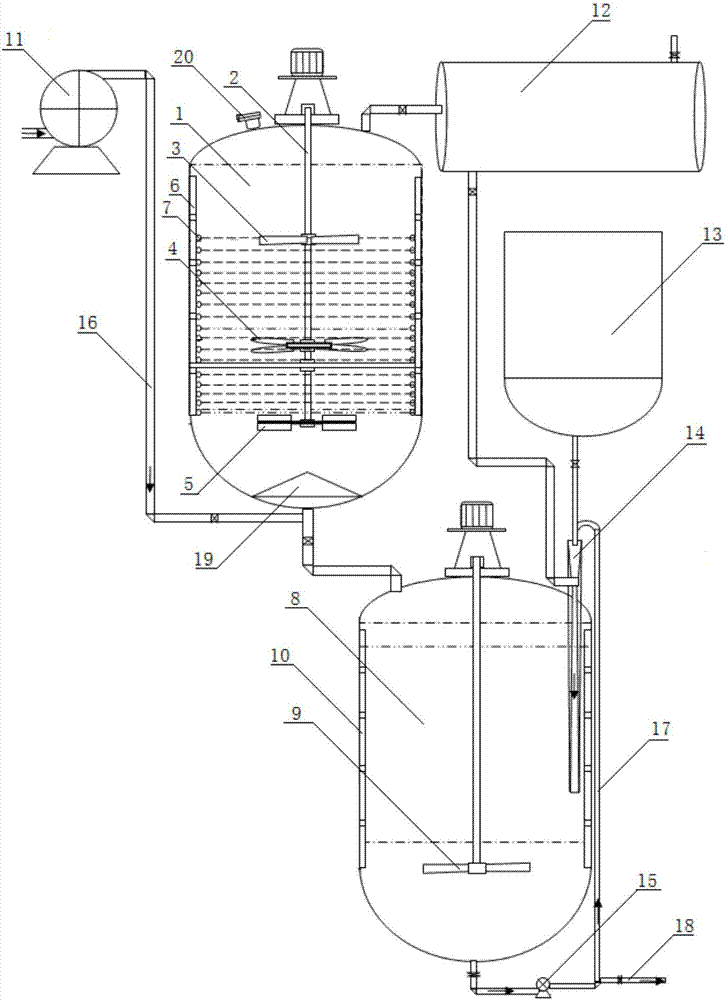

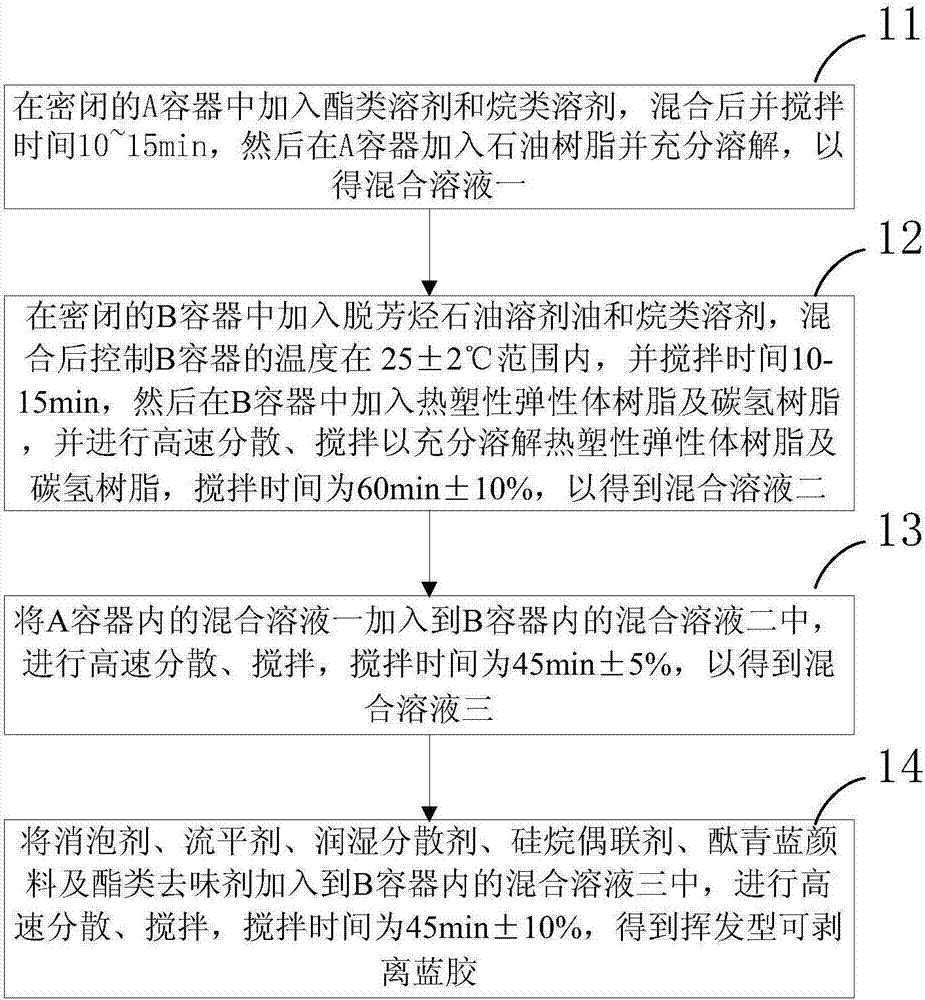

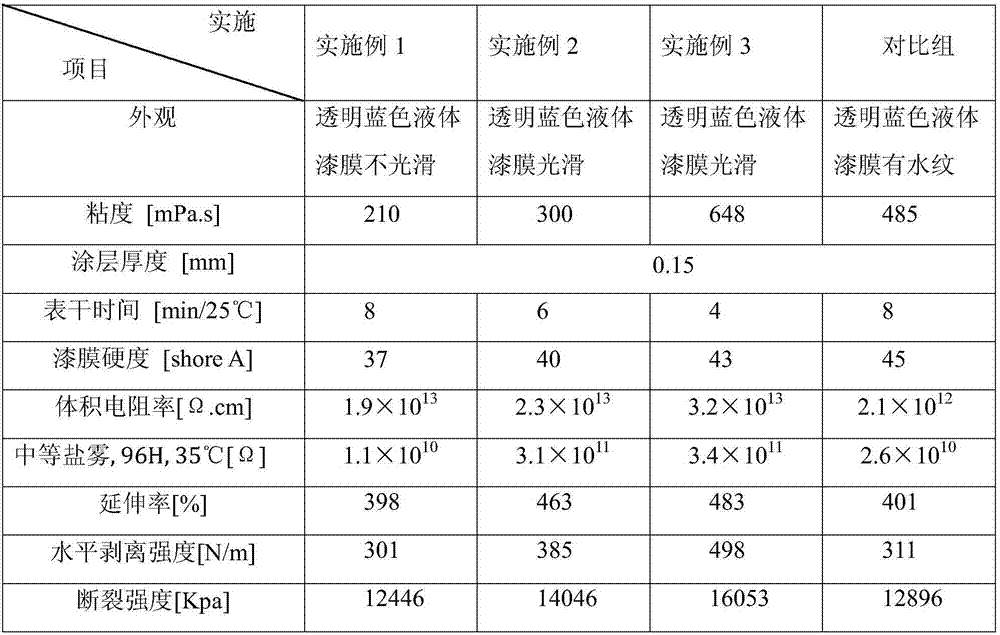

Volatile peelable blue gel and preparation method thereof

InactiveCN106957626AHigh insulation resistanceImprove insulation performanceMacromolecular adhesive additivesSolventDefoaming Agents

The invention discloses volatile peelable blue gel and a preparation method thereof. The volatile peelable blue gel is prepared from the following raw materials in parts by weight: 10 to 20 parts of thermoplastic elastomer resin, 1 to 10 parts of hydrocarbon resin, 1 to 10 parts of petroleum resin, 0.1 to 1 part of a silane coupling agent, 20 to 50 parts of dearomatic white spirit, 1 to 10 parts of an esters solvent, 10 to 30 parts of an alkanes solvent, 0.1 to 1 part of a defoaming agent, 0.1 to 1 part of a flatting agent, 0.1 to 1 part of a wetting dispersant, and 0.1 to 1 part of phthalo blue paint. The volatile peelable blue gel and the preparation method thereof provided by the invention have high insulation resistance so as to provide excellent insulation effects, have elongation exceeding 400% and high toughness so as to provide a peeling effect, and have strong adhesive force and adherence so as to provide functions of effectively preventing humidity, salt mist and moulds. In addition, the volatile peelable blue gel not only effectively protects the surface cleanness of a product, but also can protect the product from dust, salt mist and humidity.

Owner:雅拓莱焊接科技(惠州)有限公司

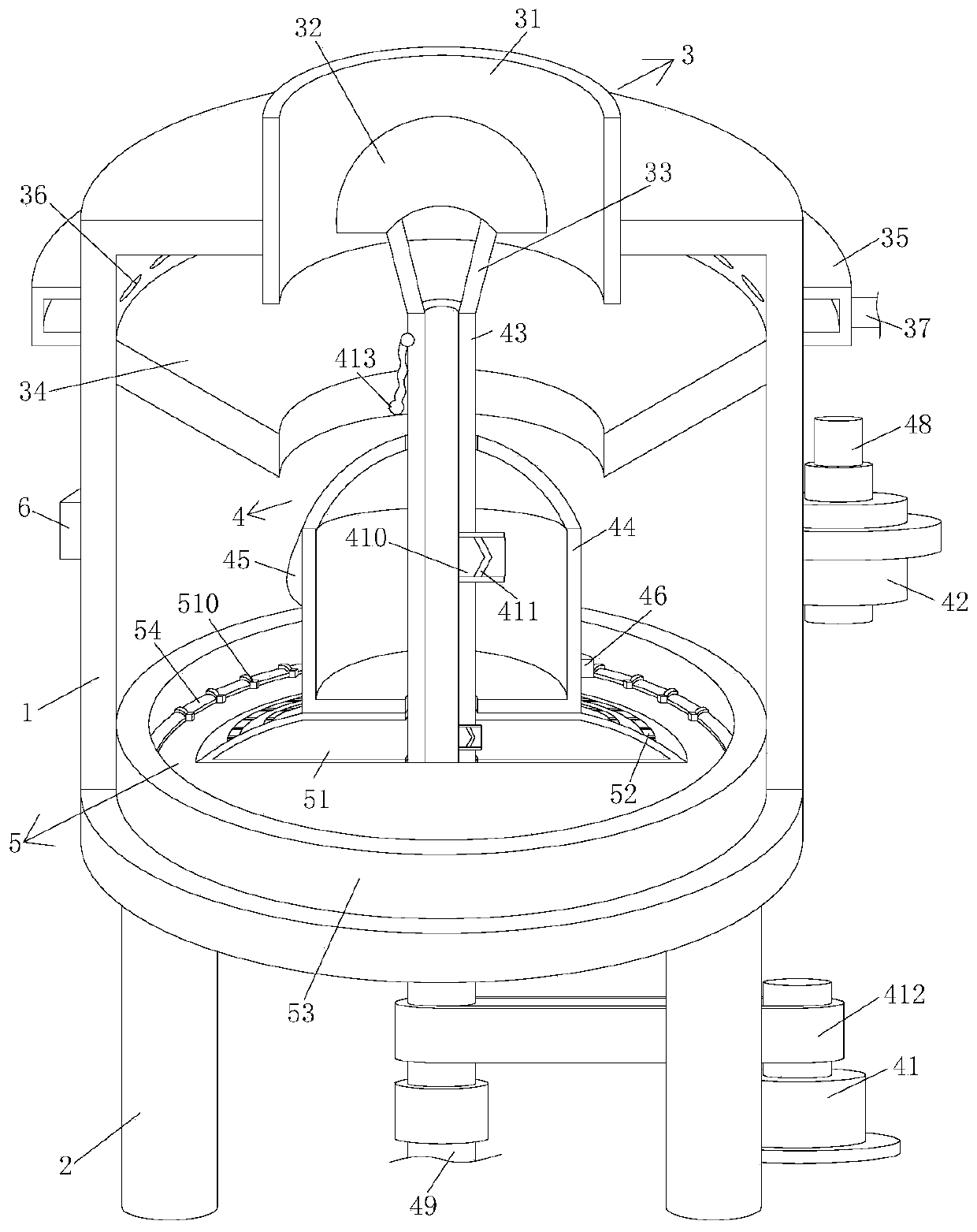

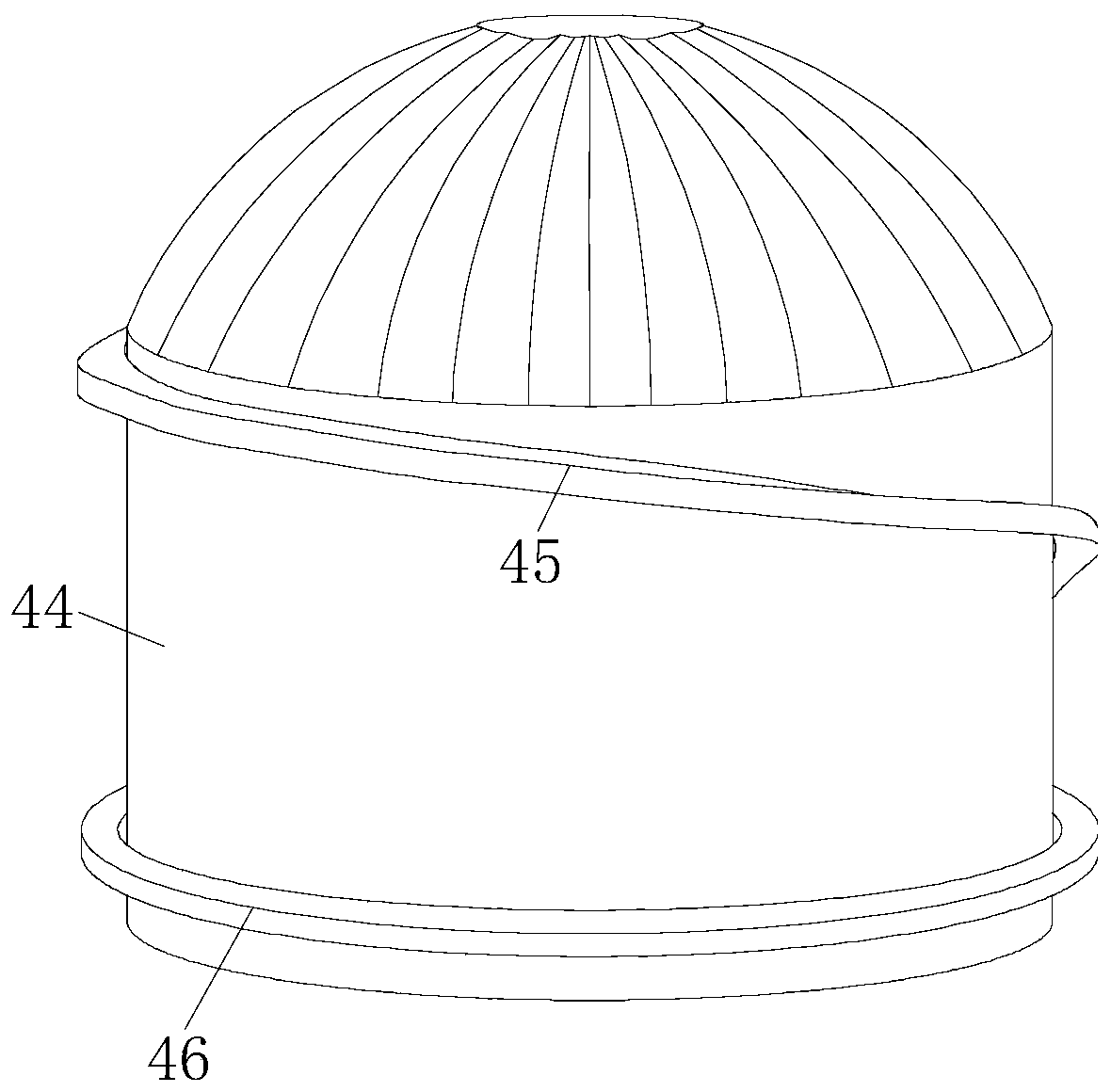

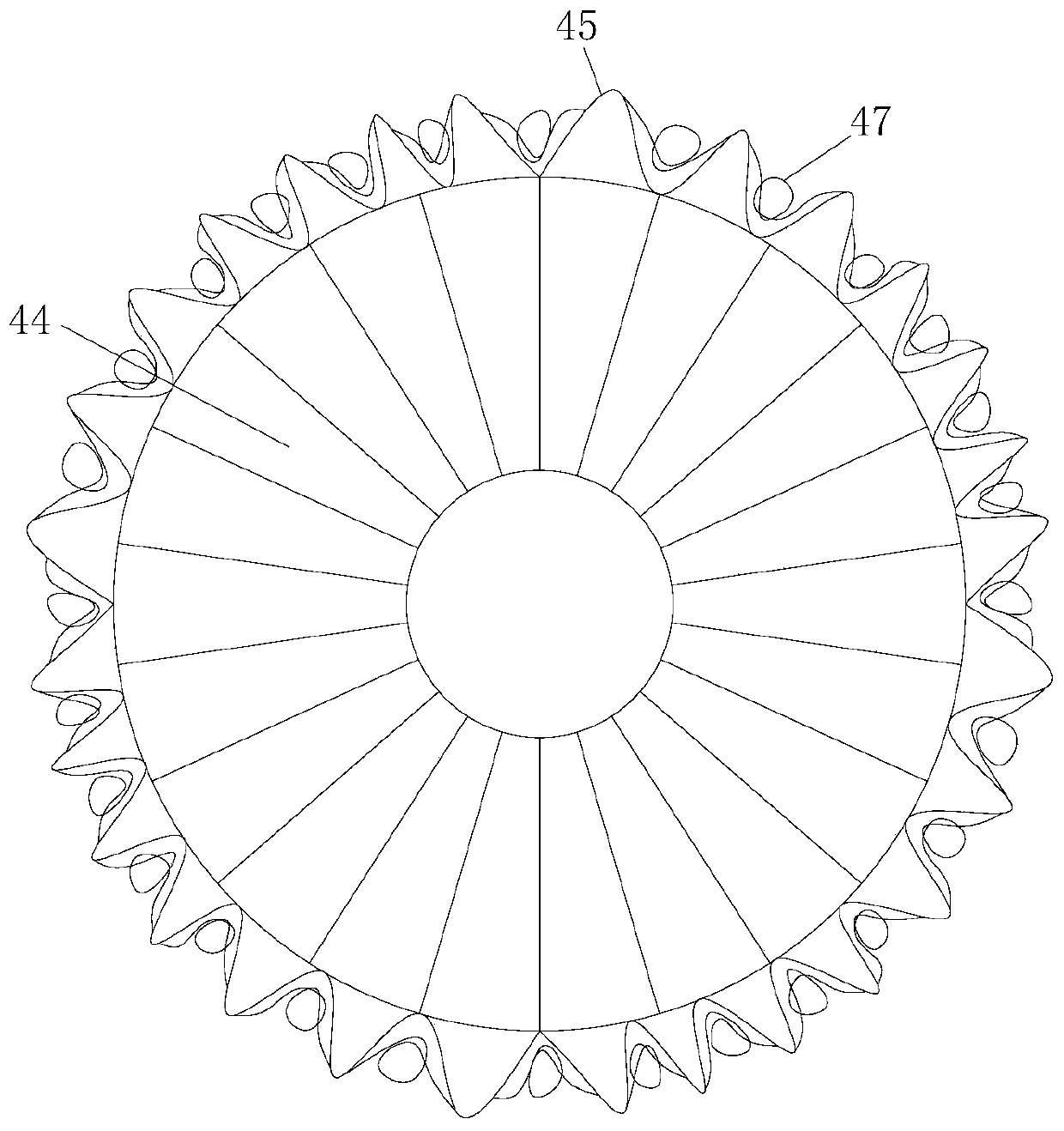

Tow printing and dyeing device based on textile processing

ActiveCN110306311AAvoid entanglementImprove printing and dyeing efficiencyTextile storage in superimposed formLiquid/gas/vapor treatment of definite length materialsPrinting inkDyeing

The invention provides a tow printing and dyeing device based on textile processing, and relates to the field of textile. The tow printing and dyeing device comprises a printing and dyeing box, supporting legs, a feeding mechanism, an offset centrifugal printing and dyeing mechanism and a storage mechanism, wherein the feeding mechanism is used for feeding tows in an umbrella scattered manner, theoffset centrifugal printing and dyeing mechanism is used for dividing the tows into different small tows and integrally spirally and rotationally printing and dyeing the tows, the storage mechanism is used for storing long printed and dyed tows, and the supporting legs are fixedly mounted at the bottom of the printing and dyeing box. According to the tow printing and dyeing device based on textile processing, the tows are scattered through a special structure by the aid of the flexibility of the tows, the tows are far away from a rotating shaft by different-level distance in the rotating process, winding can be avoided, printing and dyeing efficiency can be improved, and the device effectively solves the problems that tows are difficultly scattered by general tow printing and dyeing operation, parts of the tows cannot be sufficiently soaked in printing and dyeing liquor as the tows are stacked, winding of the tows is easily caused by swing operation, and working efficiency is affected.

Owner:曾婧

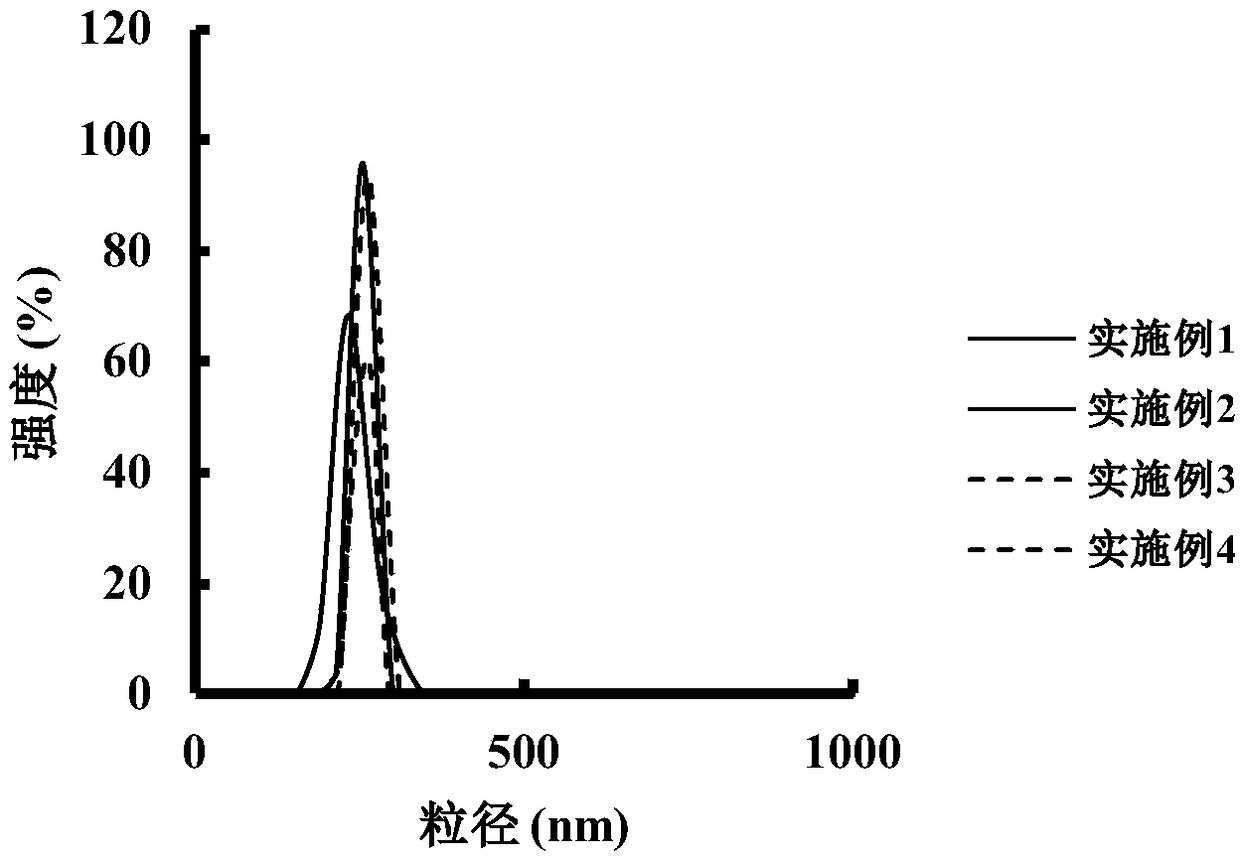

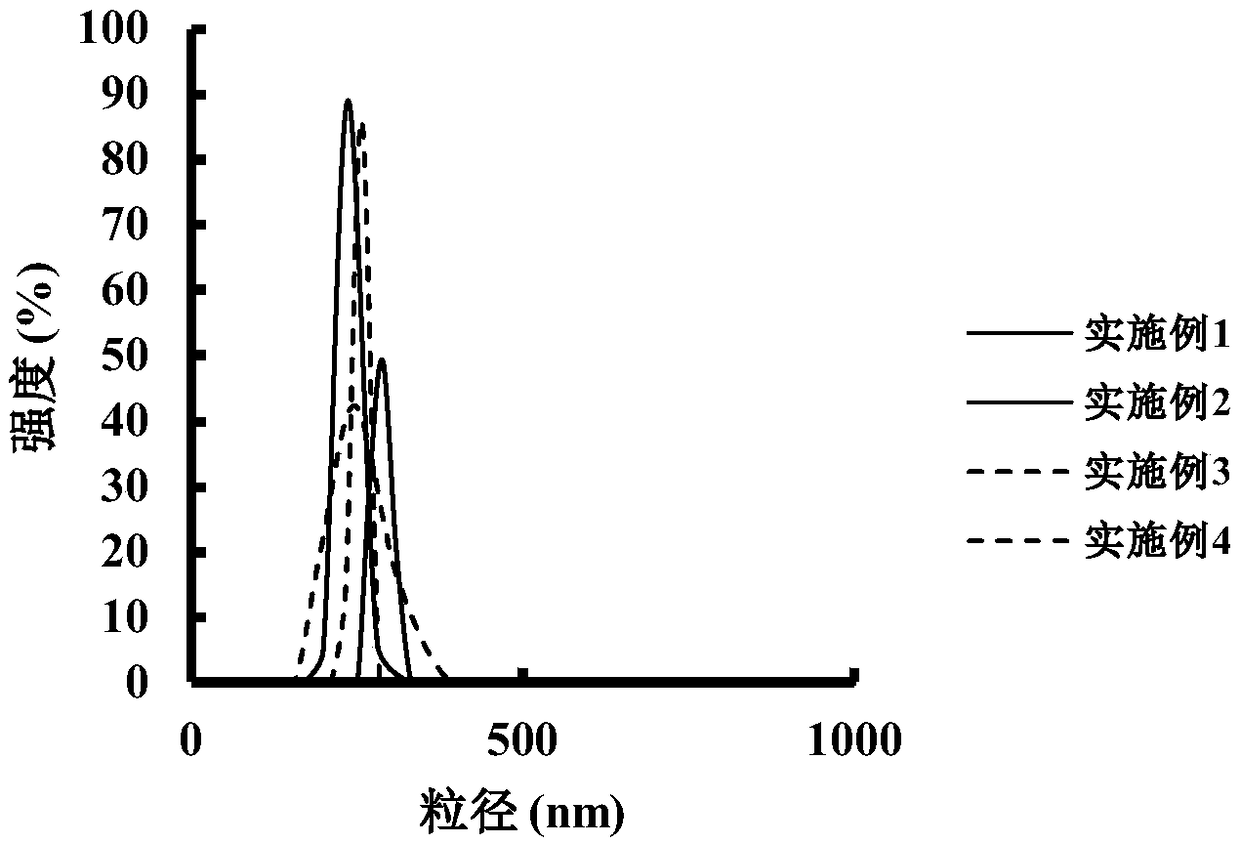

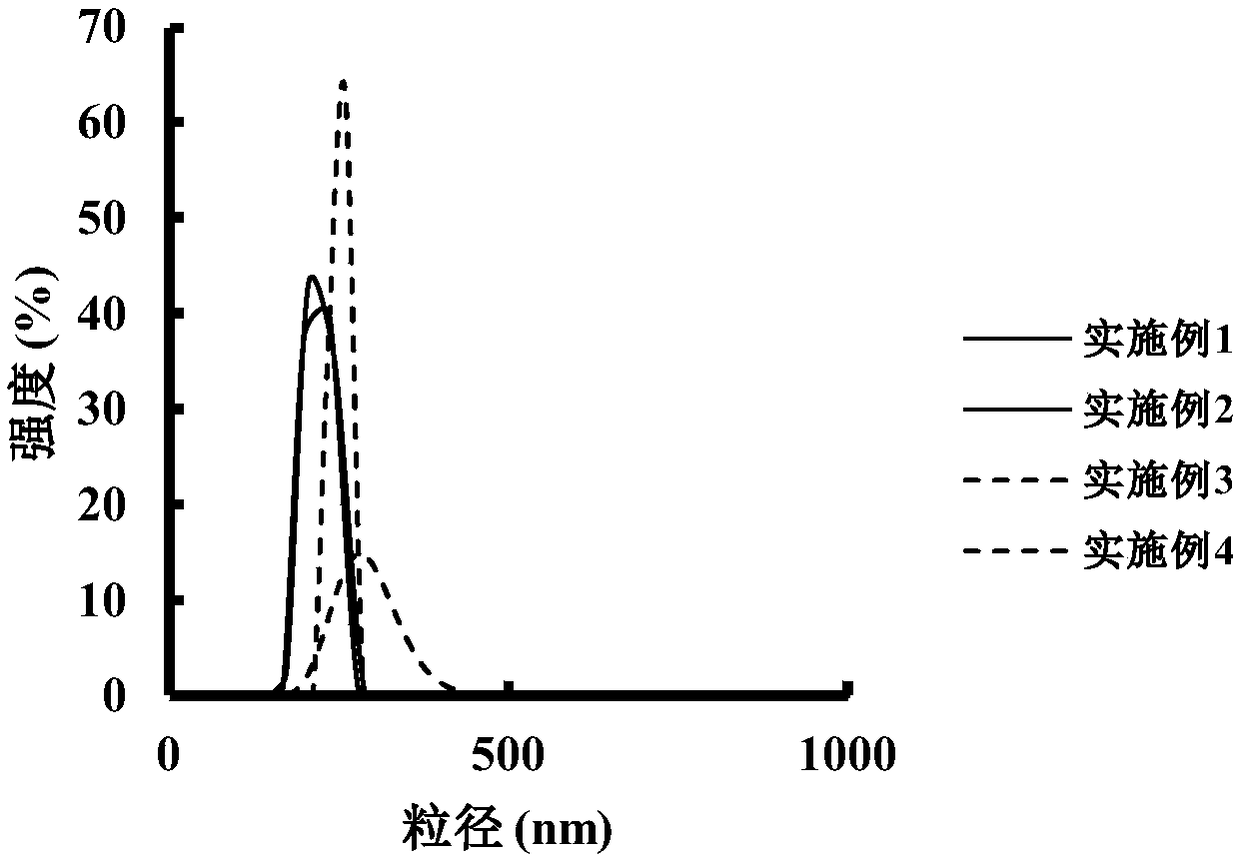

Preparation method of pseudosciaena crocea egg isolated protein-beta-carotene emulsion

The invention discloses a preparation method of a stable pseudosciaena crocea egg isolated protein-beta-carotene emulsion. The preparation method comprises the following steps of S1, preparing preotein freeze-dried powder: performing salt-dissolving protein extraction on pseudosciaena crocea eggs with a sodium chloride solution, performing centrifuging so as to obtain a supernatant, and performingfreeze-drying for standby application; S2, preparing an oil phase: performing ultrasonic heating on beta-carotene so that the beta-carotene dissolves in corn oil, and performing compounding so as toobtain the oil phase for standby application; S3, preparing an aqueous phase: preparing a protein solution of certain concentration with a buffer solution, and compounding the aqueous phase for standby application; S4, performing mixing: mixing the oil phase with the aqueous phase in a certain proportion, and performing high-speed dispersion; and S5, performing homogenizing: and performing high-pressure homogenizing so as to obtain the stable pseudosciaena crocea egg isolated protein-beta-carotene emulsion. According to the preparation method disclosed by the invention, pseudosciaena crocea egg isolated protein is used as an emulsifying agent for embedding beta-carotene, and the obtained pseudosciaena crocea egg isolated protein-beta-carotene product namely the emulsion is high in nutrientvalue and high in stability.

Owner:DALIAN POLYTECHNIC UNIVERSITY

Method for manufacturing carbon nanotube electrocatalytic electrode for organic waste water treatment

InactiveCN1763253ASpecial hollow structureImprove electrocatalytic activityWater/sewage treatmentElectrodesEpoxyCarbon nanotube

The present invention relates to the making process of carbon nanotube electrically catalytic electrode for treating organic waste water, and belongs to the field of electrode material production in electrically catalytic oxidation technology. After carbon nanotube with high catalytic activity and great specific surface area and binder PTFE in certain ratio are mixed, the mixture is cold pressed to form and wire is led out from one end of the epoxy resin cured electrode. The carbon nanotube electrically catalytic electrode has high conducting performance and low power consumption, and may be modified to obtain high electrically catalytic activity. The carbon nanotube electrically catalytic electrode is suitable for use in treating organic waste water and has high degradation rate on organic matter in waste water.

Owner:SHANGHAI UNIV

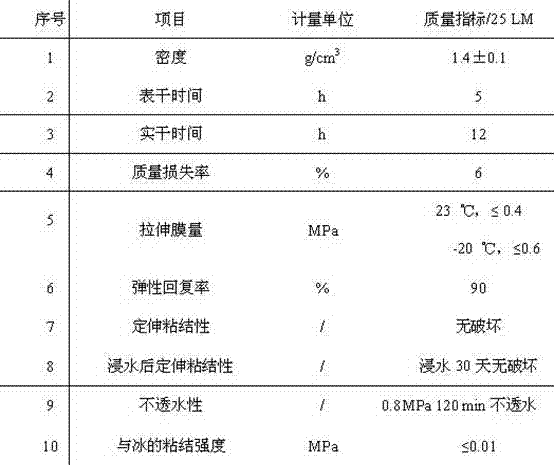

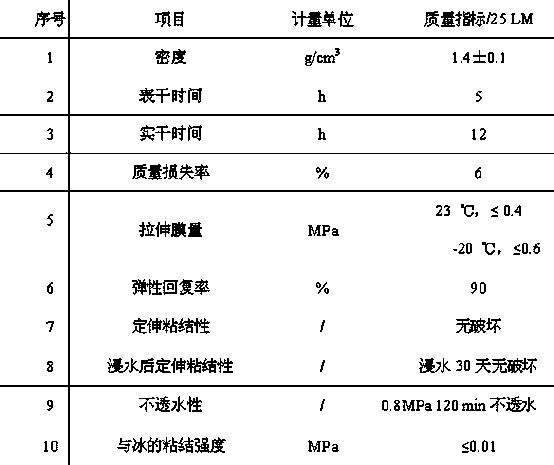

Low-modulus single-component polyurethane sealing gum for hydraulic engineering, and production method thereof

ActiveCN107286894AHigh speed dispersionImprove sealingNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesEpoxyAntioxidant

The invention discloses low-modulus single-component polyurethane sealing gum for hydraulic engineering, and a production method thereof. The low-modulus single-component polyurethane sealing gum for hydraulic engineering is prepared from polyether polyol, methylene diphenyl diisocyanate, vacuum distillate line oil, a silane coupling agent, a T-12 catalyst, a latent curing agent, epoxy resin, a non-active diluent, powdered fillers, white carbon black, carbon black and an antioxidant. The low-modulus single-component polyurethane sealing gum for hydraulic engineering and the production method thereof have the following advantages: the low-modulus single-component polyurethane sealing gum for hydraulic engineering overcomes the foaming weakness, has excellent viscosity with concrete and is environment-friendly; meanwhile, the production cost is reduced, the shelf life is prolonged, the curing time is shortened, curing formation and ice have low adhesive property, and the effect of resisting ice pull and ice push can be achieved effectively. The material has excellent performance and a plurality of hydraulic engineering characteristic indexes, and can effectively improve the sealing and water stop effects of the hydraulic architecture, enhance the safety and prolong the service life.

Owner:XINJIANG KENENG WATERPROOF & PROTECTION TECH CO LTD

Production method of solid plate perlized adhesive film paper

ActiveCN109338797AImprove visual effectsImprove wettabilitySpecial visual effect coatingsCoatings with pigmentsPolymer scienceFirming agent

The invention relates to a production method of solid plate perlized adhesive film paper. The production method is characterized that the solid plate perlized adhesive film paper is prepared by stirring and mixing 32 to 68 parts of melamine resin, a proper amount of coated aluminum pigment, 2 to 7 parts of coalescing agent, 5 to 10 parts of dispersing agent, 0.5 to 1 part of a leveling agent, 1 to2 parts of wetting agent, 1 to 5 parts of a curing agent, 10 to 25 parts of water as well as a proper amount of anti-settling agent and neutralizer, and the like. The solid plate perlized adhesive film paper provided by the invention has higher sense of metal twinkle; in addition, the water-based aluminum pigment has stable performance and is not easy to aggregate, and can be well compatible withwater.

Owner:东莞市贝辉装饰材料有限公司

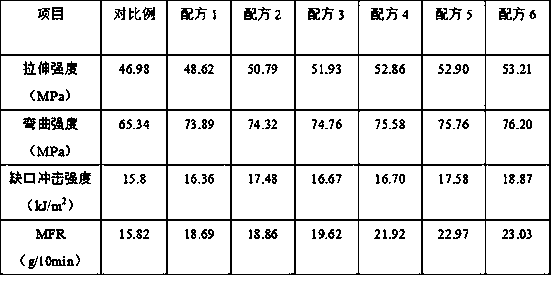

Preparation method of reinforcing and toughening lubricant specially used for ABS

The invention belongs to the technical field of lubricants, and in particular relates to a preparation method of a reinforcing and toughening lubricant specially used for ABS. The method comprises thefollowing steps: firstly nano powder is added into ethanol, a treating agent is added to modify the surface of the powder, the obtained treated nano powder is added into ethylenediamine to obtain aminated nano powder, the aminated nano powder and stearic acid are subjected to a reaction at high temperature to obtain a waxy substance, glass cellulose modified by glyceryl monostearate can be addedinto the waxy substance, extrusion granulation is performed, and therefore the reinforcing and toughening lubricant specially used for the ABS can be obtained. According to the method provided by theinvention, the prepared lubricant is added into the ABS resin, and the lubricant has good compatibility with the ABS resin, and improves the impact strength and bending strength of the ABS resin whileimproving the fluidity of the ABS resin.

Owner:常州可赛成功塑胶材料有限公司

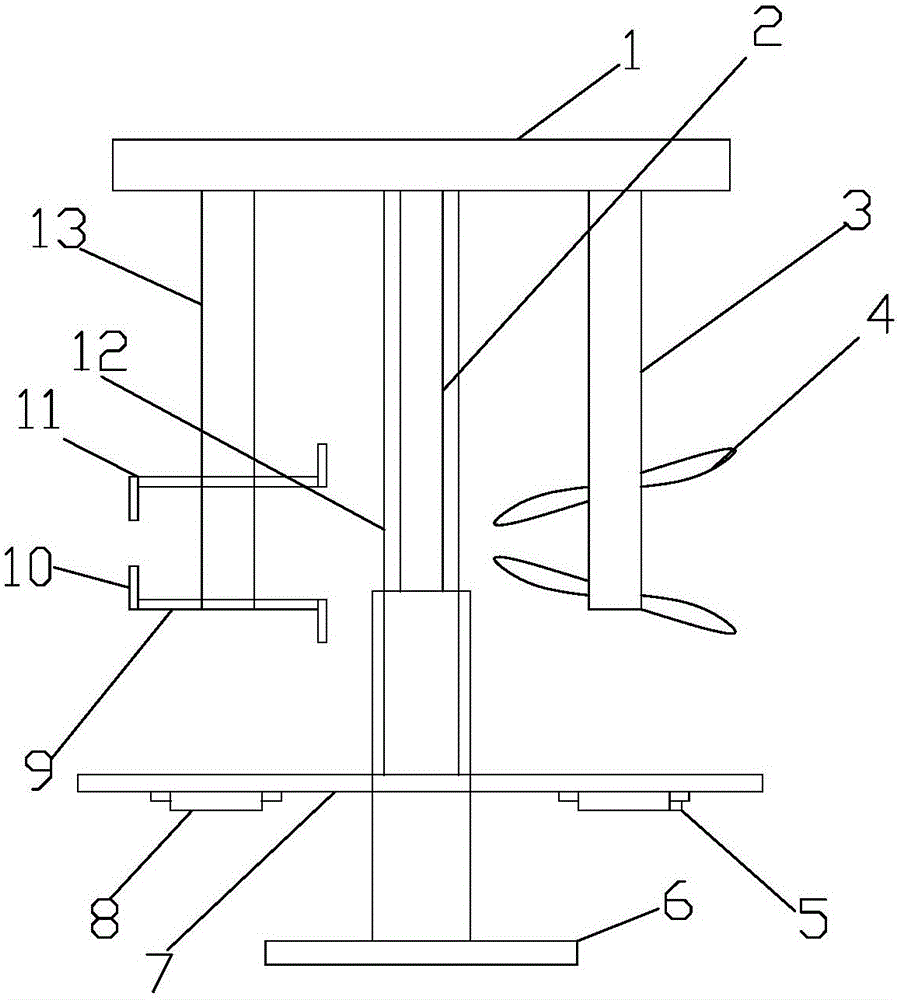

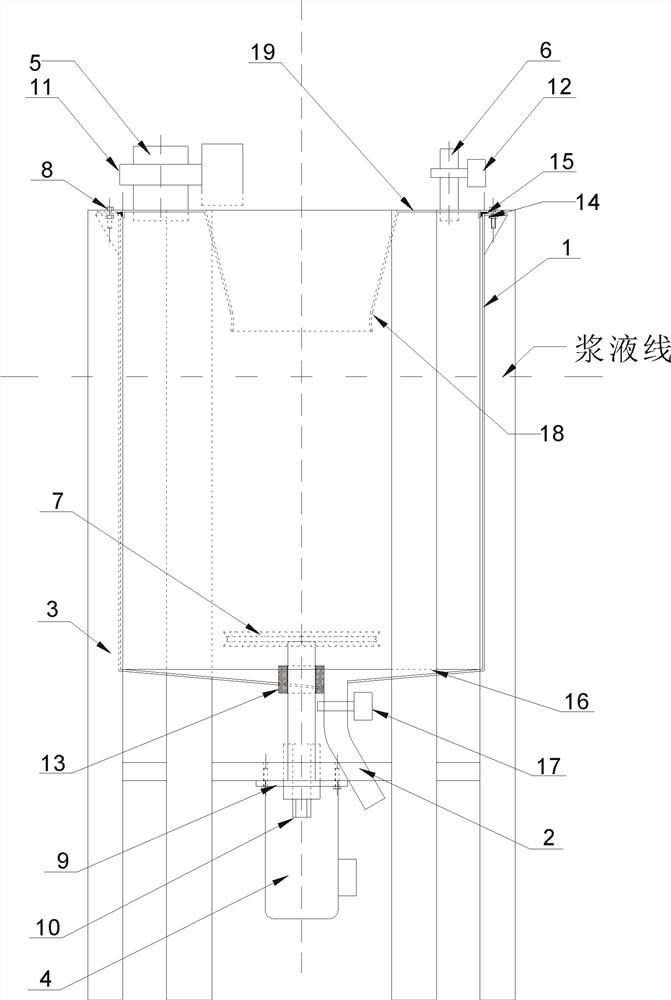

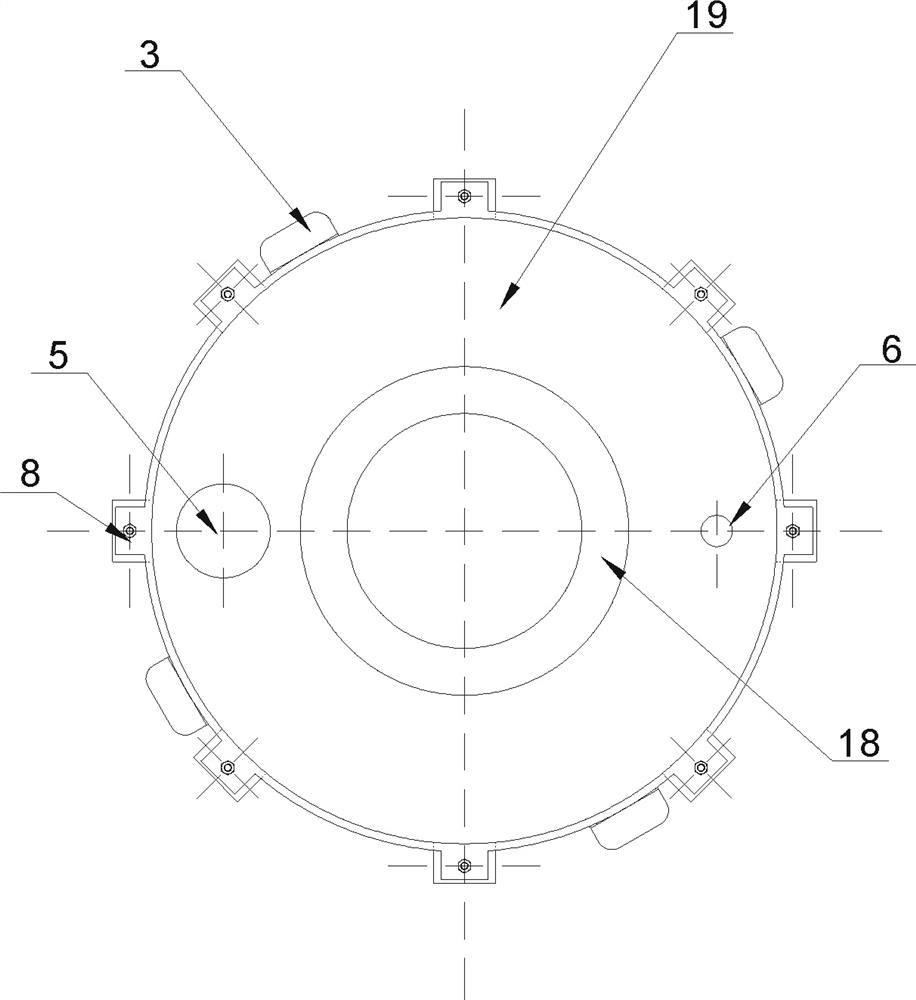

High-speed dispersing device for fire retardant slurry

InactiveCN105879737AAvoid frictional collisionsHigh speed dispersionTransportation and packagingRotary stirring mixersCircular discHydraulic cylinder

The invention discloses a high-speed dispersing device for fire retardant slurry. The device comprises a base (6), a hydraulic cylinder (2) is arranged on the base (6) and provided with a rack (1), the rack (1) is provided with a left stirring shaft (13), a middle stirring shaft (12) and a right stirring shaft (3) which are arranged downwards, the lower portion of the left stirring shaft (13) is provided with two stirring discs (11), each stirring disc (11) comprises a disc body (9), and stirring pieces (10) which are arranged in a vertically-staggered mode are arranged at the periphery of each disc body (9); the lower end of the middle stirring shaft (12) is provided with a rotating arm (7), and the rotating arm (7) is provided with rotating rollers (8); the lower portion of the right stirring shaft (3) is provided with two spiral rotary-stirring pieces (4). By means of the high-speed dispersing device, the slurry can be dispersed uniformly and stirred sufficiently, the stirring effect can be good, and stirring efficiency can be improved.

Owner:HUZHOU RUIGAO NEW MATERIALS CO LTD

Surface-tolerant coating and application thereof

The invention provides a surface-tolerant coating and an application thereof. The coating comprises an A component and a B component at a weight ratio of (100-125):100. The A component comprises, by weight, 35-55 parts of epoxy resin and 3-10 parts of a first solvent. The B component comprises, by weight, 18-40 parts of an amine curing agent and 5-15 parts of a liquid petroleum resin, which is a liquid aromatic hydrocarbon resin having the viscosity being 700-2600 mpa*s and the aromatic ring of which is connected to non-active hydroxyl. The surface-tolerant coating is excellent in penetrationperformance, the toughness of a coating film is high, and the formed coating layer is excellent in adhesive force and mechanical property.

Owner:BEIJING BSS CORROSION PROTECTION IND +1

Method for preparing silver paste used for back electrode of photovoltaic cell

InactiveCN102360628AGood dispersionImprove finenessNon-conductive material with dispersed conductive materialCable/conductor manufactureSilver pasteMolecular level

The invention discloses a method for preparing silver paste used for a back electrode of a photovoltaic cell. The method comprises the following steps of mixing a pasty solvent, a thickening agent and a diluting solvent, adding superfine silver powder and glass powder in the mixture, dispersing at a high speed in a sand mill, heating synchronously to evaporate the diluting solvent, thereby betterpromoting dispersion of the superfine silver at a molecular level, and finally grinding by using a three-roll grinder so as to prepare the silver paste for the back electrode of the photovoltaic cell. The silver paste used for the back electrode of the photovoltaic cell prepared by the method provided by the invention has good dispersivity, the fineness of the prepared paste material is less than8 microns, so that the method is suitable for being used in the preparation of photovoltaic cells in large scale.

Owner:NEW MATERIAL INST OF SHANDONG ACADEMY OF SCI

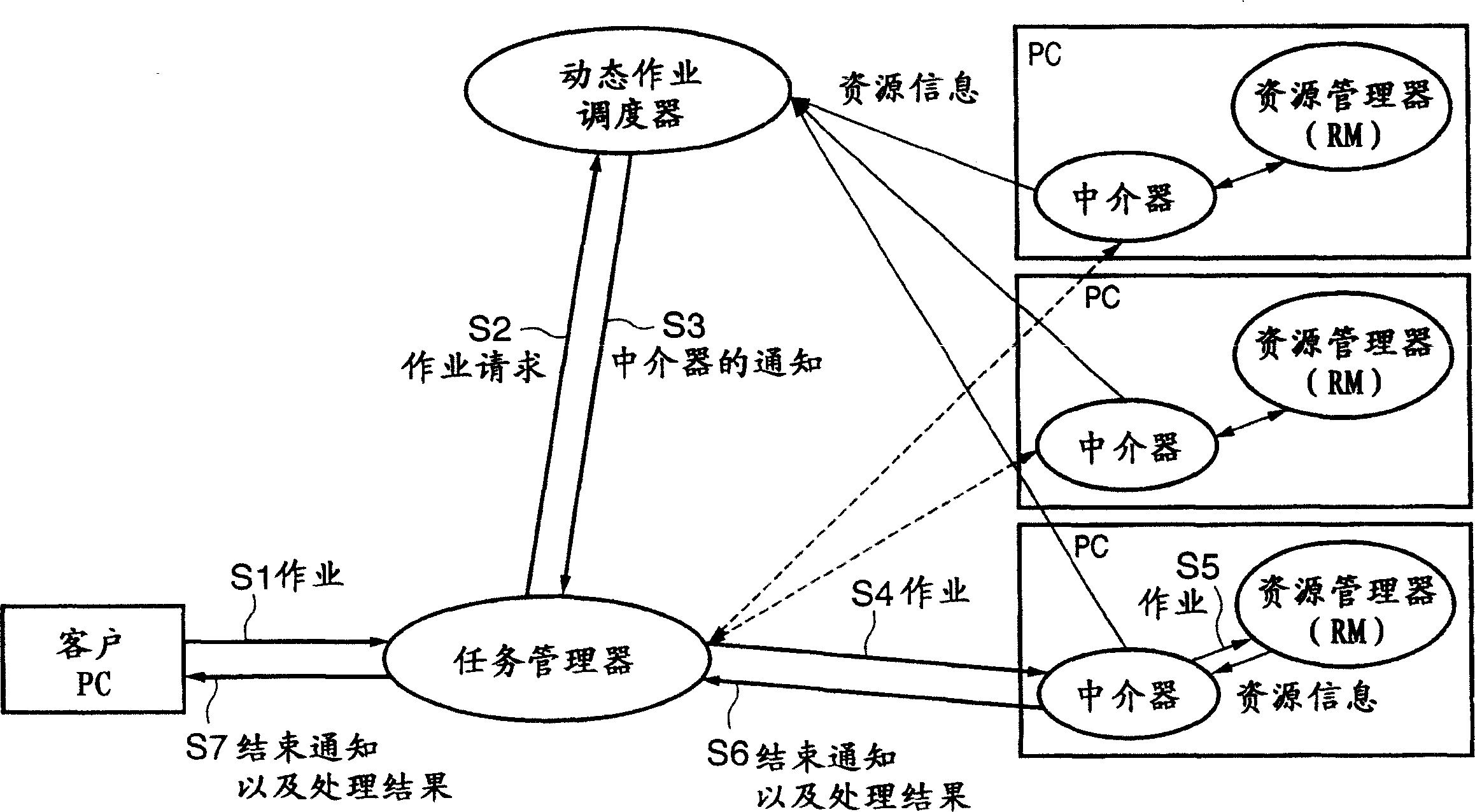

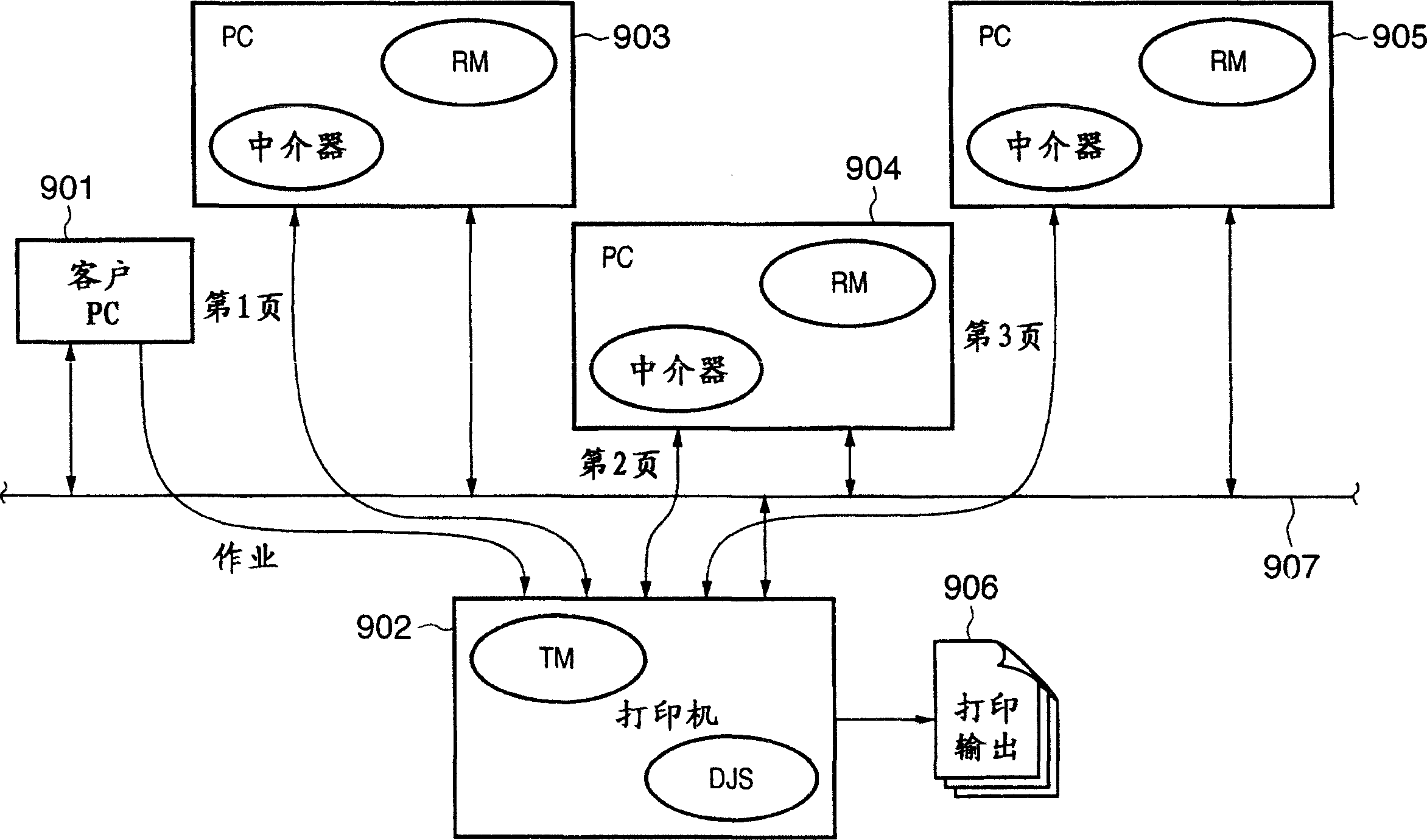

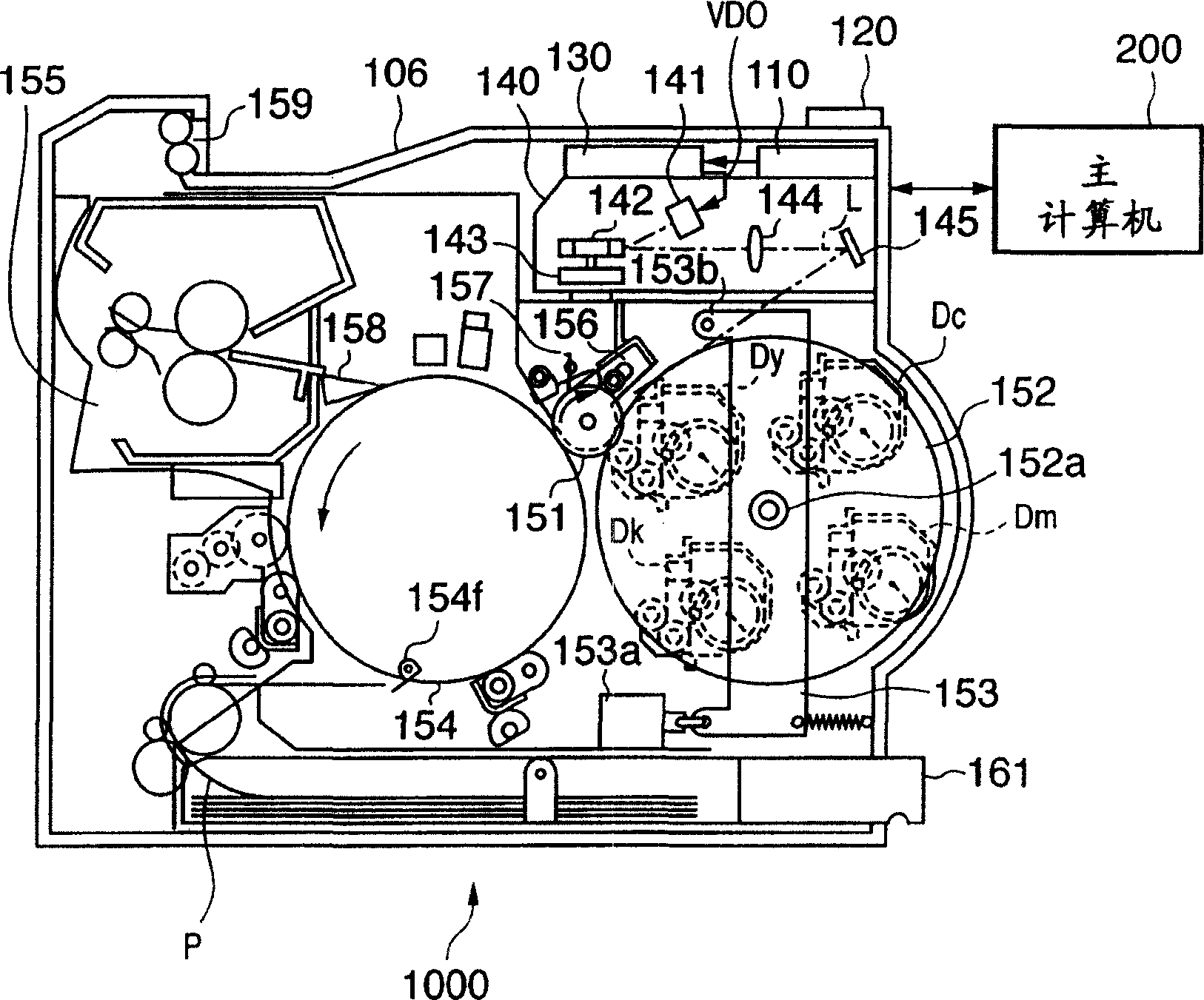

Information processing apparatus and its control method

InactiveCN1707421AHigh speed dispersionVisual presentation using printersMultiple digital computer combinationsInformation processingImaging processing

By distributing a large amount of processing among multiple devices, the mechanism that seeks high-speed processing does not perform processing allocation that considers the hardware resources of the devices that perform the distributed processing. Therefore, the drawing in the printing job is distributed among the devices connected to the computer network. During processing, determine whether to perform hardware processing or software processing (S1102, S1103), search for an image processing device that can perform hardware rendering processing or software rendering processing (S1104, S1106) from devices connected to the computer network, and determine and The result of the search is notified to the device that sent the job divided from the print job (S1108).

Owner:CANON KK

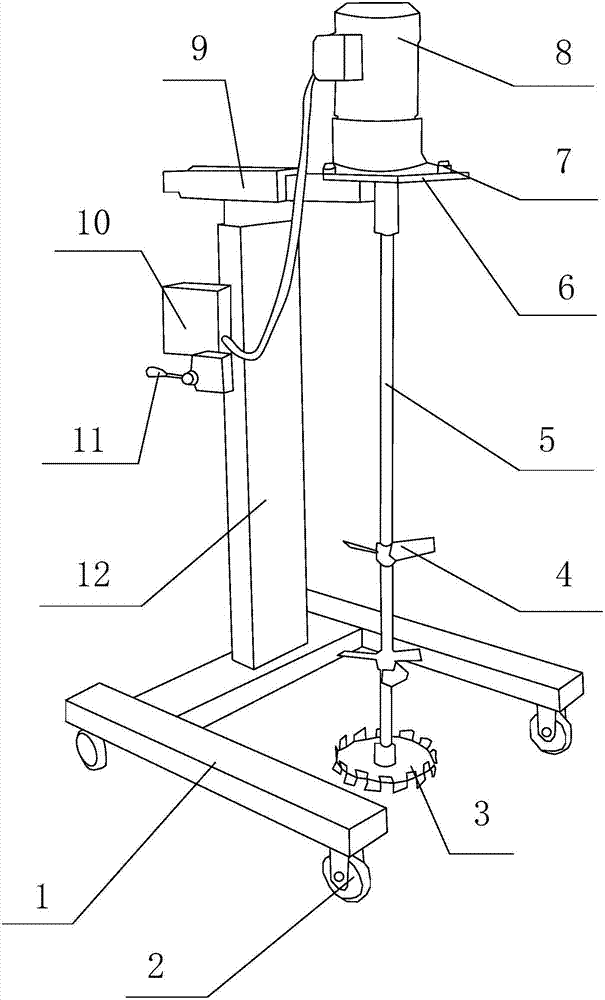

High-speed stirring system capable of moving quickly

InactiveCN107875889AHigh speed dispersionImprove impactRotary stirring mixersTransportation and packagingEngineeringSupport plane

The invention discloses a high-speed stirring system capable of moving quickly, which includes a support frame, on which a supporting column is arranged. The supporting column is provided with a mounting bench on which a motor is disposed. The motor is connected to a stirring device. Rolling wheels are disposed on the bottom of the support frame. The high-speed stirring system can perform high-speed and intensive shear, collision, crushing and dispersion to traditional Chinese medicine raw materials, so that rapidly mixing, dissolving, dispersing and refining the raw materials. The system canbe quickly moved, so that stirring position can be changed and stirring efficiency is quickly increased. The system also can achieve multi-layer stirring and increases stirring rate.

Owner:张炜

Method for manufacturing carbon nanotube electrocatalytic electrode for organic waste water treatment

InactiveCN100400714CSpecial hollow structureImprove electrocatalytic activityWater/sewage treatmentElectrodesEpoxyElectricity

The present invention relates to the making process of carbon nanotube electrically catalytic electrode for treating organic waste water, and belongs to the field of electrode material production in electrically catalytic oxidation technology. After carbon nanotube with high catalytic activity and great specific surface area and binder PTFE in certain ratio are mixed, the mixture is cold pressed to form and wire is led out from one end of the epoxy resin cured electrode. The carbon nanotube electrically catalytic electrode has high conducting performance and low power consumption, and may be modified to obtain high electrically catalytic activity. The carbon nanotube electrically catalytic electrode is suitable for use in treating organic waste water and has high degradation rate on organic matter in waste water.

Owner:SHANGHAI UNIV

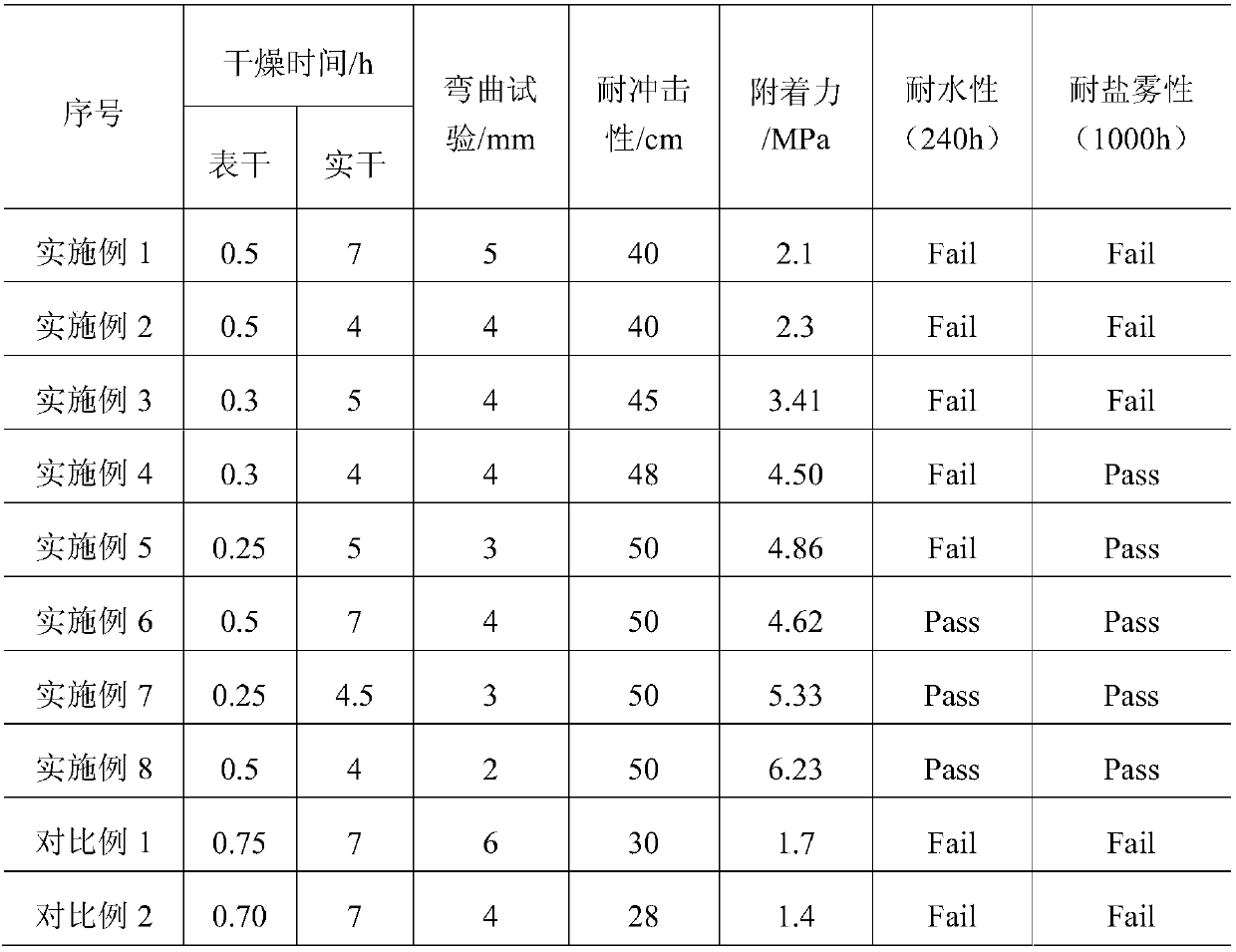

A solvent-free flexible anti-corrosion epoxy coating and its preparation method and application method

InactiveCN103788735BViscosity change rate is smallImprove flexibilityAnti-corrosive paintsGlycidyl methacrylatePoly(ethylene glycol) diglycidyl ether

The invention provides a solvent-free flexible anti-corrosion epoxy coating and a preparation method and application method thereof. In terms of mass percent, the epoxy coating includes 45 to 60 parts of epoxy resin, 10 to 15 parts of reactive diluent, 10 to 13 parts of aluminum tripolyphosphate, 7 to 10 parts of glass flakes, 2 to 3 parts of wetting Dispersion aid, 10-14 parts of filler; among them, the epoxy resin is composed of 30-40 parts of bisphenol A resin with an epoxy value of 0.54 and 15-20 parts of bisphenol A resin with an epoxy value of 0.42; reactive diluent It consists of 4-8 parts of polyethylene glycol diglycidyl ether and 6-7 parts of glycidyl methacrylate. Compared with the prior art, the epoxy coating of the present invention has the advantages of no solvent and zero VOC emission, and improves the durability and brittleness of the epoxy coating, prolongs the durability and anti-corrosion life of the coating, so it is a An environmentally friendly, flexible, long-term anti-corrosion epoxy coating.

Owner:CENT RES INST OF BUILDING & CONSTR CO LTD MCC GRP +2

Low-modulus single-component polyurethane sealant for hydraulic engineering and production method thereof

ActiveCN107286894BHigh speed dispersionImprove sealingNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesPolymer sciencePtru catalyst

The invention discloses low-modulus single-component polyurethane sealing gum for hydraulic engineering, and a production method thereof. The low-modulus single-component polyurethane sealing gum for hydraulic engineering is prepared from polyether polyol, methylene diphenyl diisocyanate, vacuum distillate line oil, a silane coupling agent, a T-12 catalyst, a latent curing agent, epoxy resin, a non-active diluent, powdered fillers, white carbon black, carbon black and an antioxidant. The low-modulus single-component polyurethane sealing gum for hydraulic engineering and the production method thereof have the following advantages: the low-modulus single-component polyurethane sealing gum for hydraulic engineering overcomes the foaming weakness, has excellent viscosity with concrete and is environment-friendly; meanwhile, the production cost is reduced, the shelf life is prolonged, the curing time is shortened, curing formation and ice have low adhesive property, and the effect of resisting ice pull and ice push can be achieved effectively. The material has excellent performance and a plurality of hydraulic engineering characteristic indexes, and can effectively improve the sealing and water stop effects of the hydraulic architecture, enhance the safety and prolong the service life.

Owner:XINJIANG KENENG WATERPROOF & PROTECTION TECH CO LTD

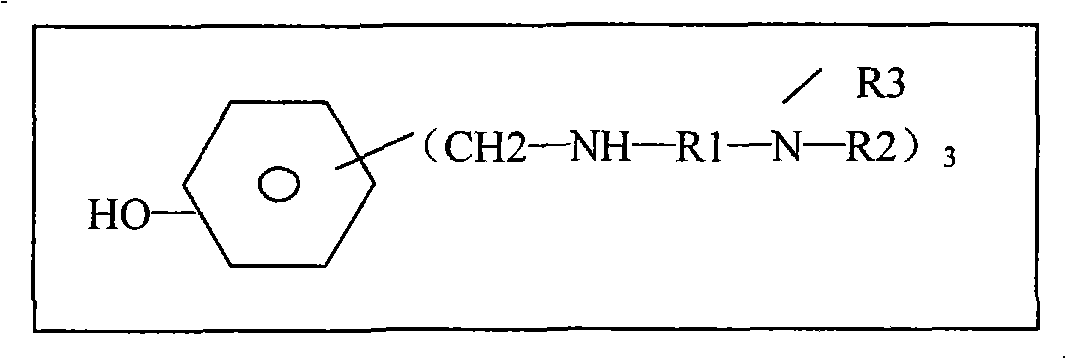

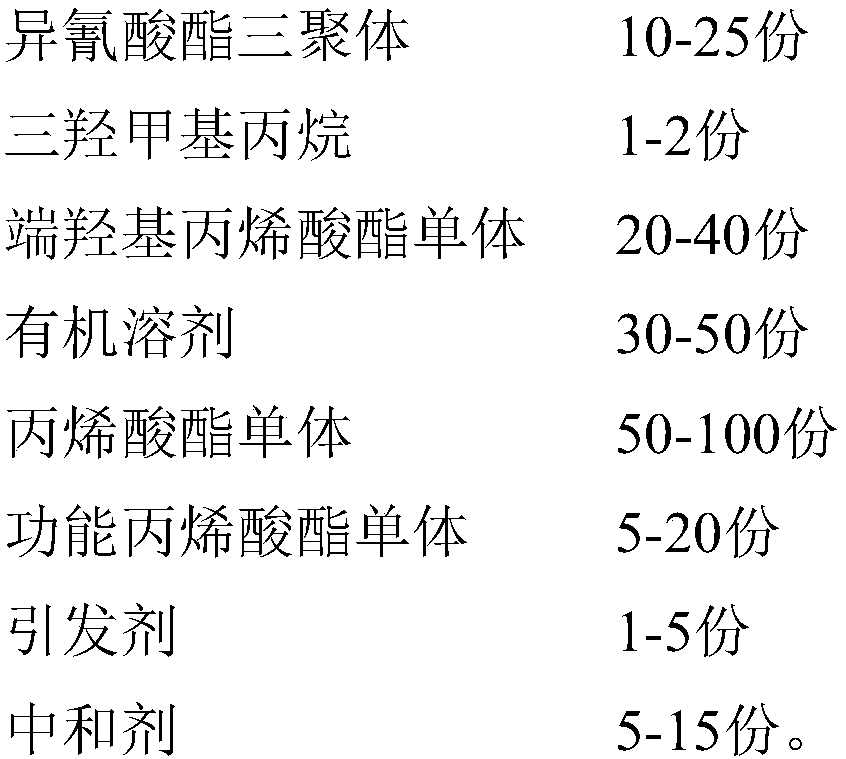

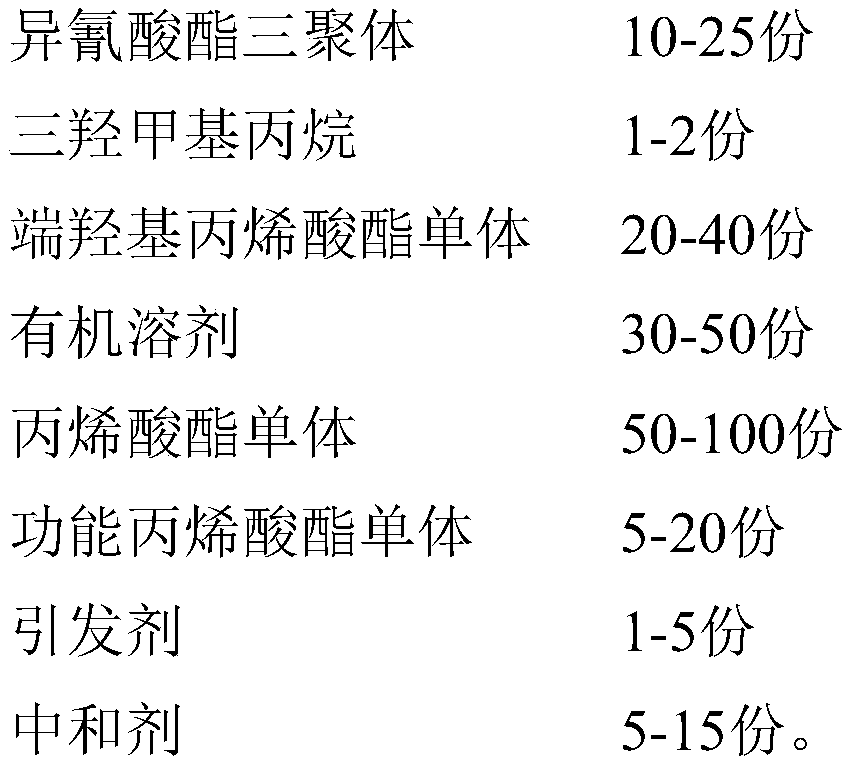

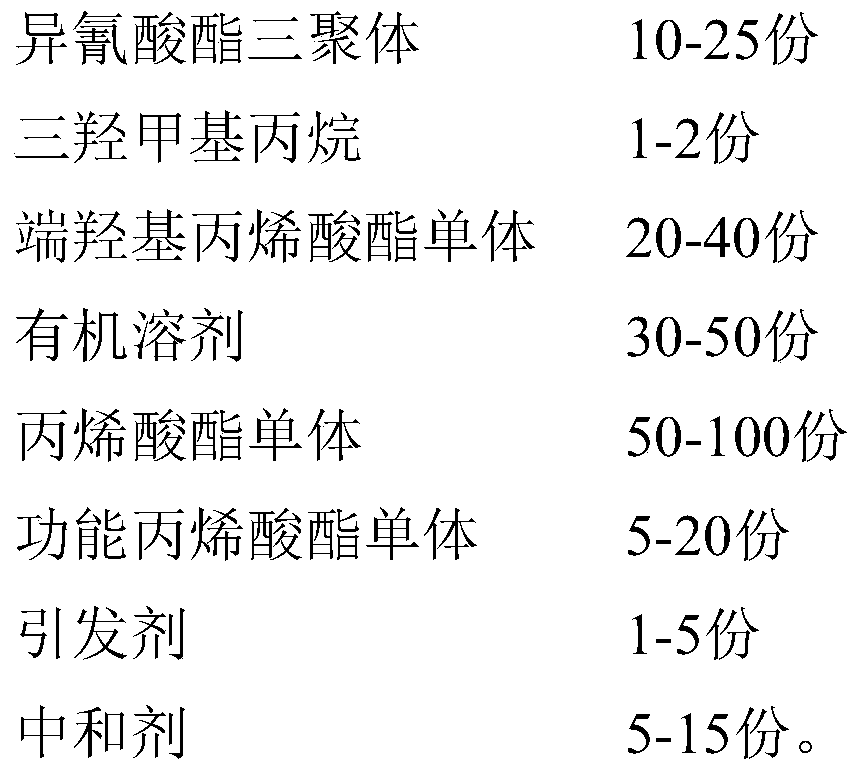

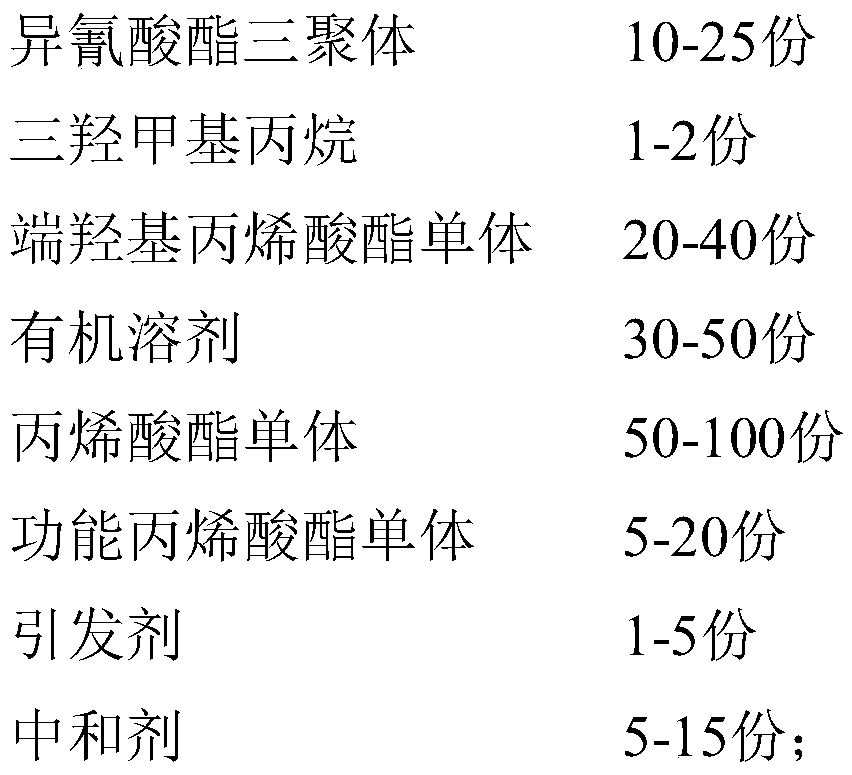

Preparation method of high-solid-content star acrylate polyurethane dispersion for coating varnish

The invention discloses a preparation method of a high-solid-content star acrylate polyurethane dispersion for coating varnish, and relates to the technical field of coating varnish. The preparation method comprises the steps of synthesizing an NCO group-containing star core A1 by using an isocyanate trimer and trimethylolpropane; synthesizing a double bond-containing star core A2 by reaction between the star core A1 and a hydroxyl-terminated acrylic monomer; adding an organic solvent into the star core A2 for diluting to obtain an A3; dropwise adding an acrylic monomer, a functional acrylic monomer and an initiator into the A3 to synthesize star acrylate polyurethane A4; then removing the solvent; neutralizing and adding deionized water for high speed dispersing, so as to prepare the high-solid-content star acrylate polyurethane dispersion. The acrylate polyurethane dispersion prepared by the method provided by the invention can form a high weather-proof coating film with high fullness and glossiness of 98 or more by matching with amino resin; the solvent content is less than 5%, the solid content is higher than 60%, and the effects of environment protection and no pollution are realized.

Owner:安徽匠星联创新材料科技有限公司

Green anti-corrosive paint for interior wall

InactiveCN100999641BNo pollutionShorten drying timeChloropene polymer coatingsAnti-corrosive paintsButyl acetatePolymer science

The present invention discloses one kind of green anticorrosive inner wall paint, which consists of n-butanol 28-30 weight portions, chlorobutadiene rubber 2.5-4.2 weight portions, butyl acetate 7-8 weight portions, petroleum resin 4-6 weight portions, DIBP 8-10 weight portions, barium sulfate 20-30 weight portions and pigment in proper amount. The preparation process of the paint includes addingthe first mentioned five components into one reactor with high speed shearing and emulsifying machine to modify the base material in the rotation speed of 4000-4500 rpm for 2 hr, adding barium sulfate and pigment and high speed shearing at 5000-5800 rpm to disperse and emulsify for more 2 hr to reach material fineness below 60 micron, filtering and packing. The paint has the features of no toxicity, no bad smell, high anticorrosive and waterproof property, high adhesion, etc.

Owner:邹文和

Preparation method of high-solid star-shaped acrylic polyurethane dispersion for varnish

ActiveCN108676126BGood dispersionHigh speed dispersionCoatingsPolyurethane dispersionPolymer science

The invention discloses a method for preparing a high-solid star-shaped acrylic polyurethane dispersion used for varnishes, and relates to the technical field of varnishes, using isocyanate trimer and trimethylolpropane to synthesize star cores containing NCO groups A1, star core A1 reacts with hydroxyl-terminated acrylic acid monomer to synthesize star core A2 containing double bonds, add organic solvent to star core A2 to dilute to obtain A3, then add acrylic acid monomer, functional acrylic monomer, and initiator dropwise to A3 to synthesize Star-shaped acrylic polyurethane A4, and then remove the solvent, and after neutralization, add deionized water to disperse at high speed to obtain a high-solid star-shaped acrylic polyurethane dispersion. The acrylic polyurethane dispersion prepared in the present invention can form a highly weather-resistant varnish coating film with extremely high fullness and a gloss of more than 98 by coordinating with amino resin; and the solvent content is lower than 5%, and the solid content is higher than 60%, which is environmentally friendly and pollution-free .

Owner:安徽匠星联创新材料科技有限公司

Green anti-corrosive paint for interior wall

InactiveCN100999641AShort drying timeGood water resistanceChloropene polymer coatingsAnti-corrosive paintsPipingToxicity

The present invention discloses one kind of green anticorrosive inner wall paint, which consists of n-butanol 28-30 weight portions, chlorobutadiene rubber 2.5-4.2 weight portions, butyl acetate 7-8 weight portions, petroleum resin 4-6 weight portions, DIBP 8-10 weight portions, barium sulfate 20-30 weight portions and pigment in proper amount. The preparation process of the paint includes adding the first mentioned five components into one reactor with high speed shearing and emulsifying machine to modify the base material in the rotation speed of 4000-4500 rpm for 2 hr, adding barium sulfate and pigment and high speed shearing at 5000-5800 rpm to disperse and emulsify for more 2 hr to reach material fineness below 60 micron, filtering and packing. The paint has the features of no toxicity, no bad smell, high anticorrosive and waterproof property, high adhesion, etc.

Owner:邹文和

Bottom-mounted high-speed dispersing device for preparing silicon mortar for concrete

PendingCN112121691AHigh speed dispersionEasy to checkRotary stirring mixersTransportation and packagingElectric machineEngineering

The invention provides a bottom-mounted high-speed dispersing device for preparing silicon mortar for concrete. The bottom-mounted high-speed dispersing device has the following beneficial effects that after improvement, the bottom-mounted high-speed dispersing device comprises a dispersing barrel, a mortar discharging pipe, supporting legs, a variable-frequency dispersing motor, a powder feedingopening, a dispersing liquid feeding opening, a high-speed dispersing disc, a flow guide ring hinge plate and a barrel upper cover; wherein the top of the dispersing barrel is connected with the barrel upper cover, the variable-frequency dispersing motor is fixed below the dispersing barrel through a high-speed motor flange plate, the variable-frequency dispersing motor is connected with the high-speed dispersing disc through a corresponding high-speed bearing and a shaft, and the high-speed shaft and the dispersing disc extend into the dispersing barrel from the bottom of the dispersing barrel and are close to the bottom of the dispersing barrel; and a discharge port electromagnetic valve and a slurry discharge pipe are arranged at the bottom of the dispersion barrel. The high-speed dispersion device is relatively simple in structure, can realize high-speed dispersion of silicon mortar through reasonable mechanical structure and system integration, has relatively high dispersion efficiency, and is easy for inspection and maintenance of dispersion blades.

Owner:四川省川铁枕梁工程有限公司

Method for preparing silver paste used for back electrode of photovoltaic cell

InactiveCN102360628BHigh speed dispersionGood dispersionNon-conductive material with dispersed conductive materialCable/conductor manufactureSilver pasteMolecular level

The invention discloses a method for preparing silver paste used for a back electrode of a photovoltaic cell. The method comprises the following steps of mixing a pasty solvent, a thickening agent and a diluting solvent, adding superfine silver powder and glass powder in the mixture, dispersing at a high speed in a sand mill, heating synchronously to evaporate the diluting solvent, thereby betterpromoting dispersion of the superfine silver at a molecular level, and finally grinding by using a three-roll grinder so as to prepare the silver paste for the back electrode of the photovoltaic cell. The silver paste used for the back electrode of the photovoltaic cell prepared by the method provided by the invention has good dispersivity, the fineness of the prepared paste material is less than8 microns, so that the method is suitable for being used in the preparation of photovoltaic cells in large scale.

Owner:NEW MATERIAL INST OF SHANDONG ACADEMY OF SCI

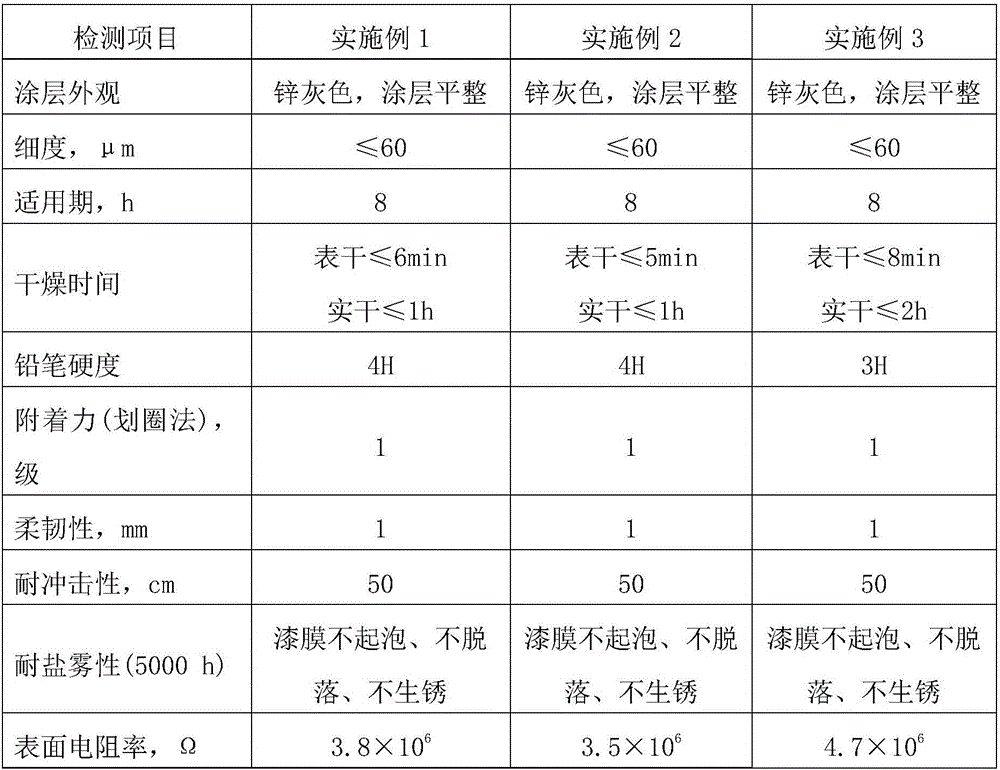

A kind of antistatic paint on steel structure surface and preparation method thereof

InactiveCN103788726BGood for condensationIncrease crosslink densityElectrically-conductive paintsCarbon nanotubeSlurry

The invention provides a antistatic paint for a steel structure surface and a preparation method thereof. The paint is prepared by mixing zinc-aluminum alloy powder slurry and ethyl orthosilicate slurry in a mass ratio of 3:1-5:1. The ethyl orthosilicate in the ethyl orthosilicate slurry is subjected to hydrolytic condensation under the action of a catalyst, and a furfural-furfuryl alcohol resin is added as a modifier into the zinc-aluminum alloy powder slurry. After the zinc-aluminum alloy powder slurry and ethyl orthosilicate slurry are mixed, the furfural-furfuryl alcohol resin is cured to release water molecules when meeting with acid so as to promote the further condensation of the ethyl orthosilicate hydrolytic condensation substances, and the furfural-furfuryl alcohol resin and the zinc-aluminum alloy powder react to form a interpenetrating network, thereby enhancing the crosslinking density between the paint and the steel structure substrate surface and increasing the wettability and adhesive force of the coating for the substrate.Preferably, a carbon nanotube dispersion solution and conductive mica powder can be added into the zinc-aluminum alloy powder slurry to correspondingly improve the antistatic property of the obtained coating. Therefore, the protective paint is suitable for various steel storage tank internal and external walls, large bridges, ships, offshore oil drilling platforms and other steel structure surfaces.

Owner:CENT RES INST OF BUILDING & CONSTR CO LTD MCC GRP +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com