High-speed stirring system capable of moving quickly

A high-speed stirring and fast-moving technology, which is applied to mixer accessories, mixers with rotating stirring devices, dissolution, etc., can solve the problems of large volume and weight of the mixing tank, inconvenient movement, slow stirring efficiency, etc., to improve the stirring efficiency Efficiency, diversification of stirring positions, and the effect of increasing the stirring rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

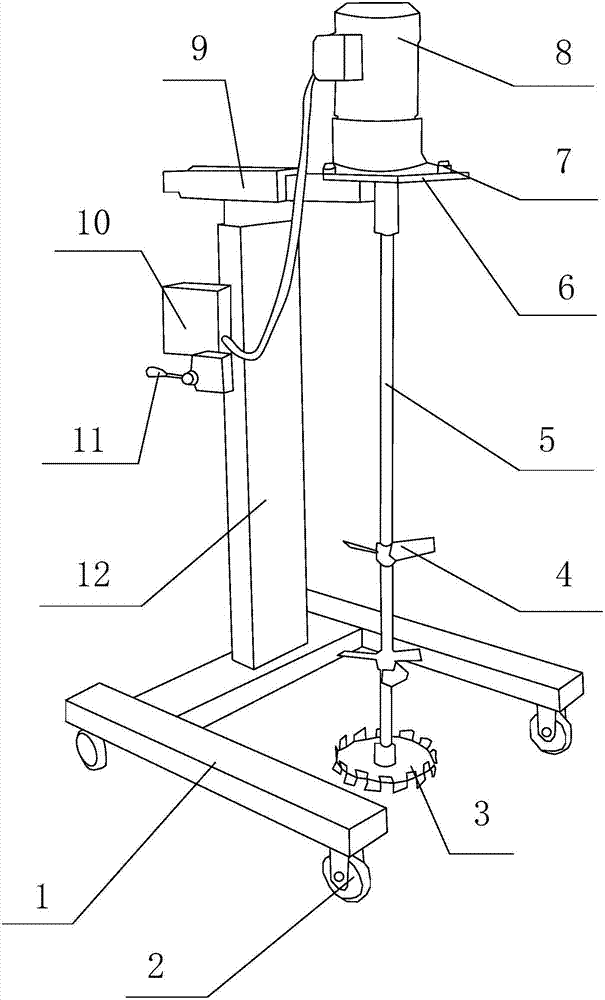

[0016] Such as figure 1 As shown, the high-speed stirring system capable of rapid movement includes a support frame 1, a support column 12 is provided on the support frame 1, a mounting platform 9 is provided on the support column 12, and a motor is provided on the mounting platform 9. 8. The motor 8 is connected with a stirring device, and the bottom end of the support frame 1 is provided with a roller 2 . The movement of the device is realized by the roller 2, so that the next stirring position can be reached quickly.

[0017] The stirring device includes a dispersing disc 3 and a stirring blade 4 , the dispersing disc 3 is provided with a rotating shaft 5 , and the end of the rotating shaft 5 away from the dispersing disc 3 passes through the stirring blade 4 and is connected to a motor 8 . The raw materials in the mixing barrel are agitated at multiple levels through the dispersing disc 3 and the stirring blade 4, the rotation speed of the raw materials in the barrel is i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com