Surface-tolerant coating and application thereof

A low surface treatment and coating technology, applied in the field of anti-corrosion of steel materials, which can solve the problems of lack of permeability and paint film toughness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

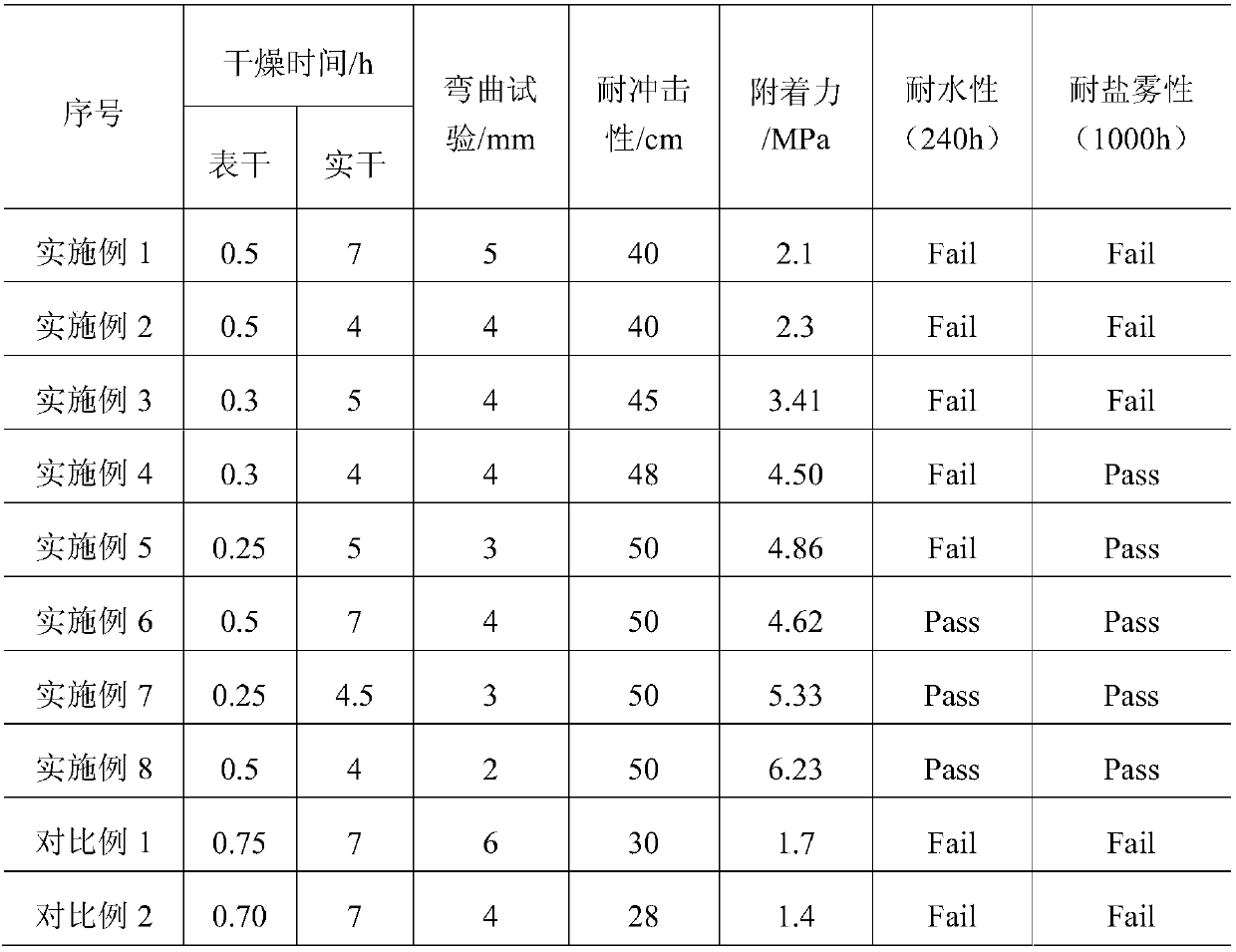

Examples

preparation example Construction

[0043] Preparation of component A: put the base material resin and solvent into the tank, start the high-speed disperser, the rotation speed of the disperser is 800-1000r / min, after 10-20min, slowly add pigments and fillers and optional additives while stirring , high-speed dispersion and grinding;

[0044] Preparation of component B: add amine curing agent, liquid petroleum resin and additives into the tank in sequence, and disperse evenly;

[0045] Before use, mix A and B components in a certain proportion and stir evenly to obtain a low surface treatment coating.

Embodiment 1

[0047] The composition of low surface treatment coating in the present embodiment is:

[0048] Component A: a total of 55g of bisphenol A epoxy resin (epoxy resin E51) with an epoxy value of 0.48-0.54, a total of 10g of a solvent (benzyl alcohol: xylene = 1:2), a total of rheological agent M-5 0.5g, wetting and dispersing agent Anti Terra 204 0.25g in total;

[0049] Component B: a total of 40g of BS-T33 phenalkamine from Zhenjiang Baisui Chemical Factory, a total of 15g of liquid petroleum resin RutgersNovares LA 300;

[0050] When used, components A and B are mixed in a weight ratio of 100:100.

Embodiment 2

[0052] The composition of low surface treatment coating in the present embodiment is:

[0053] Component A: a total of 35g of bisphenol A epoxy resin (epoxy resin E51) with an epoxy value of 0.48 to 0.54, a total of 3g of a solvent (benzyl alcohol: xylene = 1:2), a total of 3g of a rheological agent M-5 0.5g, wetting and dispersing agent Anti Terra 204 0.25g in total;

[0054] Component B: a total of 18g of BS-T33 phenalkamine from Zhenjiang Baisui Chemical Factory, a total of 5g of liquid petroleum resin RutgersNovares LA 300;

[0055] When used, components A and B are mixed in a weight ratio of 125:100.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com