Volatile peelable blue gel and preparation method thereof

A volatile, blue glue technology, applied in the direction of adhesives, adhesive additives, polymer adhesive additives, etc., can solve the problems of residual glue residue, long time required for complete curing speed, cumbersome process, etc., to achieve strong adhesion and Adhesiveness, excellent insulation effect, and simple production method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

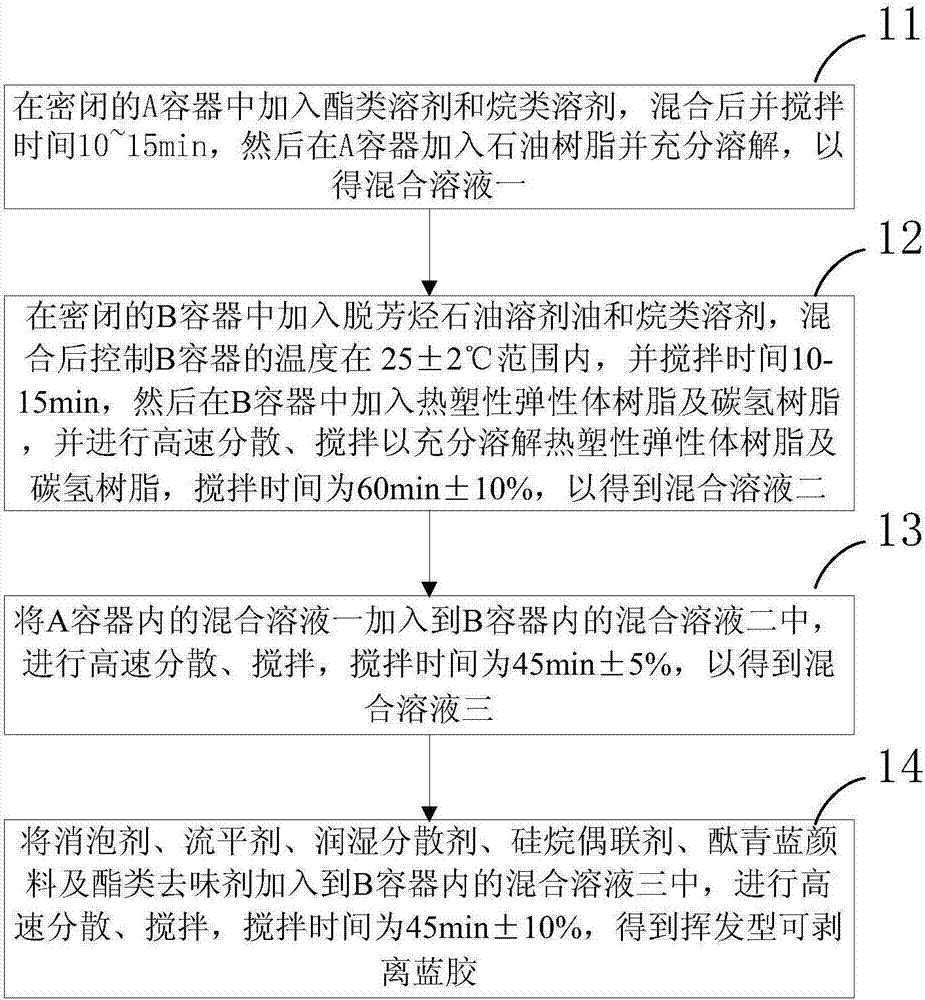

[0036] Such as figure 1 Shown, the present invention also provides a kind of preparation method of volatile strippable blue glue, comprises the following steps:

[0037] Step 11. Add an ester solvent and an alkane solvent into the airtight container A, mix and stir for 10-15 minutes, then add petroleum resin into the container A and fully dissolve it to obtain a mixed solution 1;

[0038] Step 12. Add dearomatized petroleum spirit and alkanes to the closed container B. After mixing, control the temperature of the B container within the range of 25±2°C, and stir for 10-15 minutes, and then add thermoplastic elastomer to the B container. resin and hydrocarbon resin, and perform high-speed dispersion and stirring to fully dissolve the thermoplastic elastomer resin and hydrocarbon resin, and the stirring time is 60min±10% to obtain the mixed solution 2;

[0039] Step 13. Add mixed solution 1 in container A to mixed solution 2 in container B, disperse and stir at a high speed, and t...

Embodiment 1

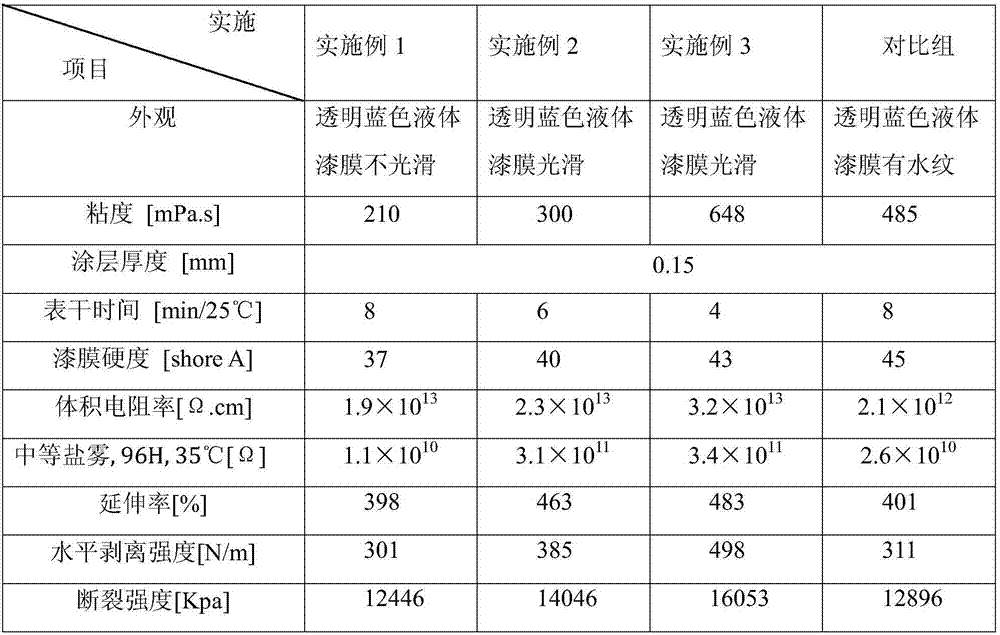

[0044] Volatile peelable blue glue, calculated in parts by weight, its raw material composition and content are as follows: 13 parts of thermoplastic elastomer resin, 4 parts of hydrocarbon resin, 3 parts of petroleum resin, 0.5 part of silane coupling agent, dearomatized petroleum spirit 50 parts, 6 parts of ester solvent, 22 parts of alkanes solvent, 0.5 part of defoamer, 0.3 part of leveling agent, 0.5 part of wetting and dispersing agent, 0.2 part of phthalocyanine blue pigment. According to the preparation method of volatile peelable blue glue, the above raw materials are dispersed and stirred at high speed to obtain volatile peelable blue glue with three anti-salt (salt spray, moisture-proof, mold-proof) functions and resistance insulation protection functions.

Embodiment 2

[0046] Volatile peelable blue glue, calculated in parts by weight, its raw material composition and content are as follows: 14.5 parts of thermoplastic elastomer resin, 6 parts of hydrocarbon resin, 5 parts of petroleum resin, 0.5 part of silane coupling agent, dearomatized petroleum spirit 43 parts, 6 parts of ester solvent, 22 parts of alkanes solvent, 0.7 part of defoamer, 0.5 part of leveling agent, 0.5 part of wetting and dispersing agent, 0.3 part of phthalocyanine blue pigment. According to the preparation method of volatile peelable blue glue, the above raw materials are dispersed and stirred at high speed to obtain volatile peelable blue glue with three anti-salt (salt spray, moisture-proof, mold-proof) functions and resistance insulation protection functions.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com