Preparation method of pseudosciaena crocea egg isolated protein-beta-carotene emulsion

A technology of carotene and protein isolation, which is applied in food ingredients, food shaping, food science, etc., can solve the problems of color degradation, biological activity reduction, bioavailability reduction, etc., and achieves a simple and easy preparation method with good stability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0036] The present invention provides a preparation method of large yellow croaker roe protein isolate-β-carotene emulsion, taking large yellow croaker roe protein isolate and β-carotene, and the preparation steps are as follows:

[0037] S1. Use a sodium chloride solution with a concentration of 0.1-1mol / L to extract protein from large yellow croaker roe, the ratio of solid to liquid is (1:10)-(1:20) g / mL, centrifuge at 5000-10000rpm / min for 10-30min, Take the supernatant (i.e. protein extract), freeze-dry in vacuum at -25-50°C for 60-72 hours to obtain protein freeze-dried powder for later use;

[0038] S2. Ultrasonic heating of β-carotene at 10-30 kHz, 50-55° C. for 10-20 minutes, dissolving it in corn oil, and preparing an oil phase with a mass concentration of β-carotene of 0.05%-0.1% for use;

[0039] S3. Reconstitute the freeze-dried protein powder obtained in step S1 with PBS of pH 7-9, 5-15 mmol / L, and prepare an aqueous phase with a protein concentration of 2-5 mg / mL...

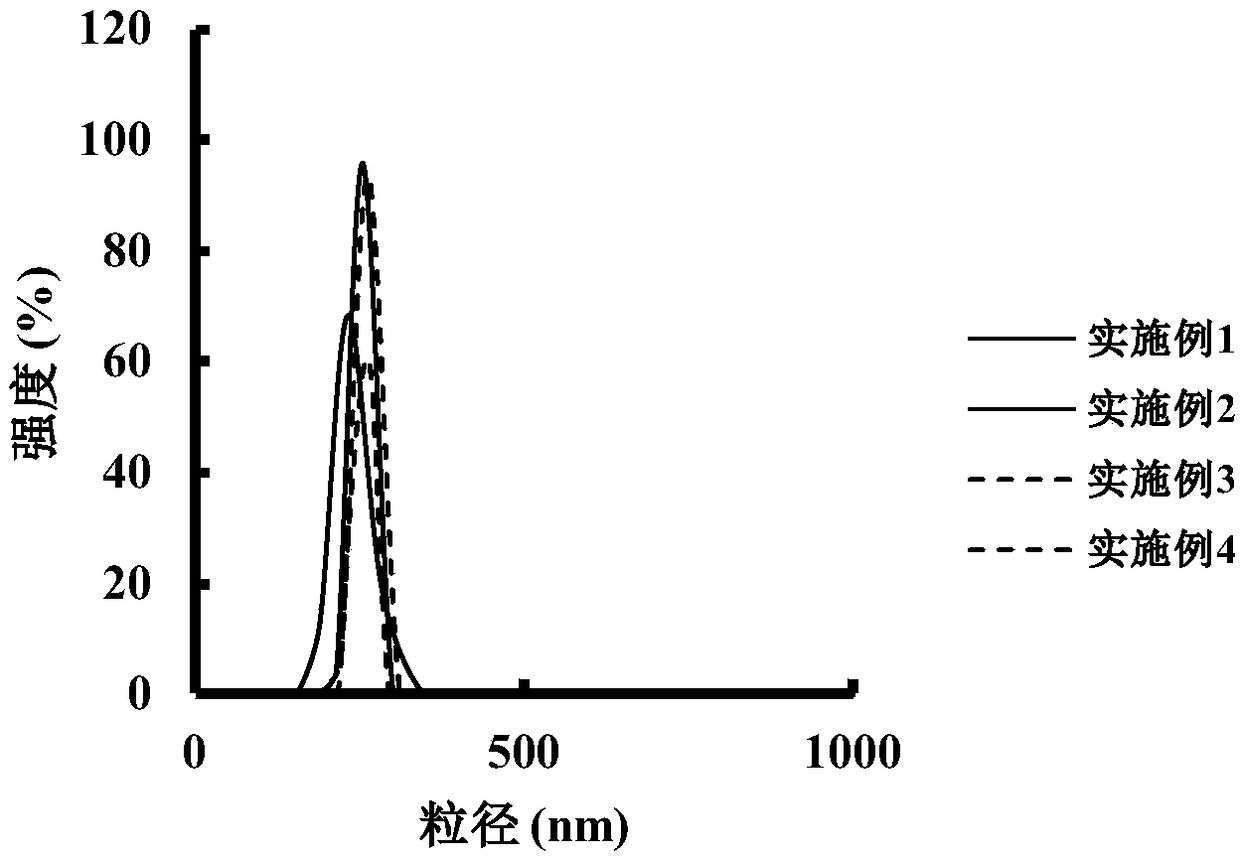

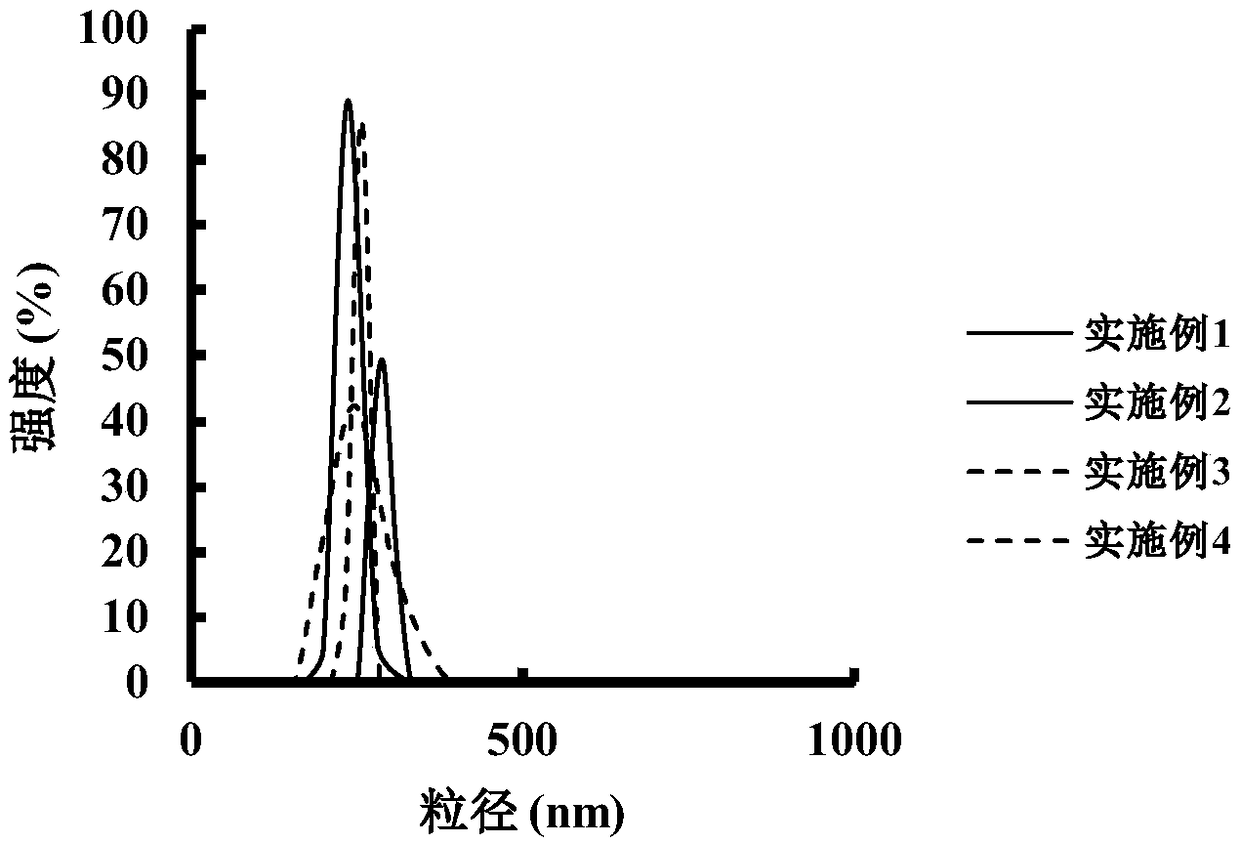

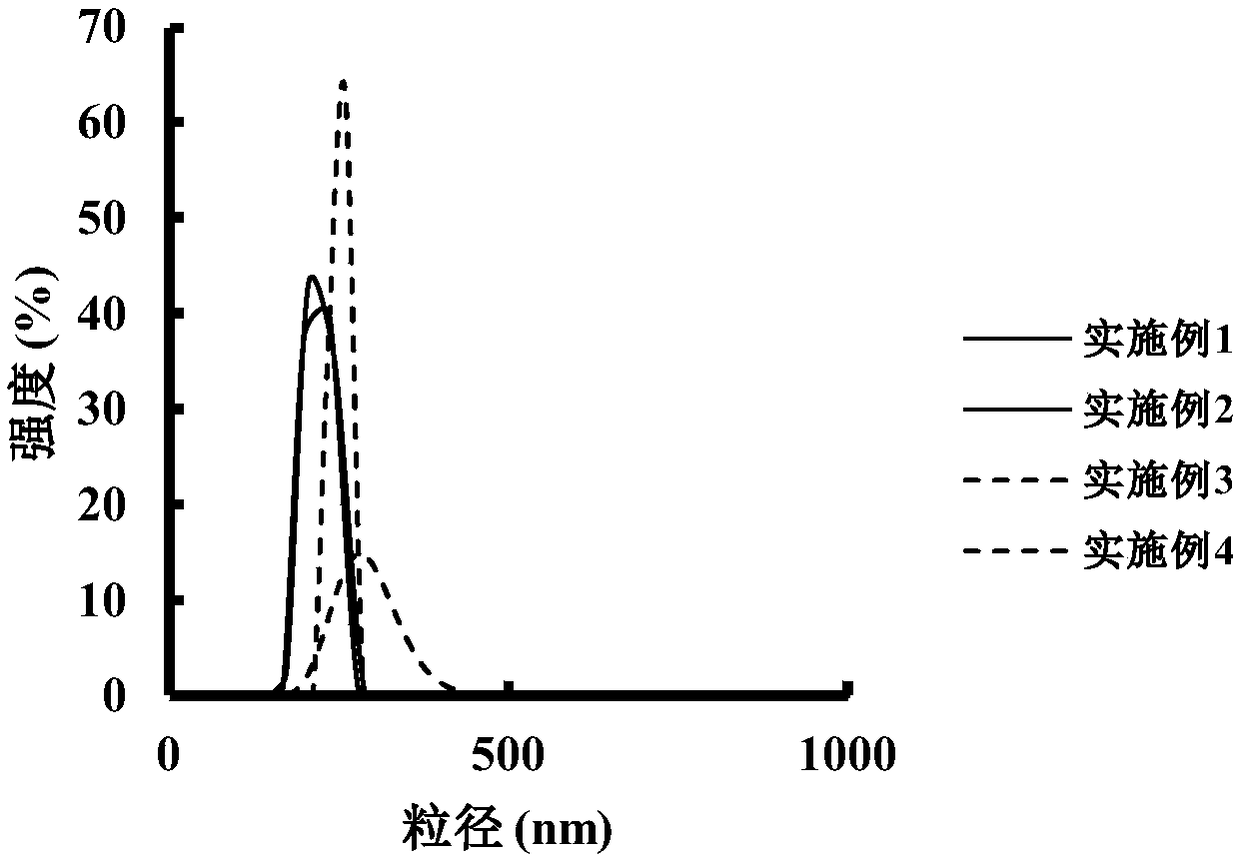

Embodiment 1

[0043]A preparation method of large yellow croaker roe protein isolate-β-carotene emulsion, taking large yellow croaker roe protein isolate and β-carotene, and its preparation steps are as follows:

[0044] S1, the large yellow croaker roe is carried out protein extraction with the sodium chloride solution of concentration 0.6mol / L, the solid-liquid ratio 1:20g / mL of large yellow croaker roe and sodium chloride solution, 5000rpm / min centrifugal 30min, get supernatant ( That is, protein extract), vacuum freeze-drying at -25°C for 60 hours to obtain protein freeze-dried powder for future use;

[0045] S2. Ultrasonic heating of β-carotene at 10 kHz and 50° C. for 20 minutes to dissolve it in corn oil, and prepare an oil phase with a mass concentration of β-carotene of 0.1% for use;

[0046] S3. Reconstitute the freeze-dried protein powder obtained in step S1 with pH 8, 10 mmol / L PBS, and prepare an aqueous phase with a protein concentration of 2 mg / mL for use;

[0047] S4. Mix t...

Embodiment 2

[0050] S1. Use a sodium chloride solution with a concentration of 0.6mol / L to extract protein from large yellow croaker roe, the ratio of solid to liquid is 1:20g / mL, centrifuge at 5000rpm / min for 30min, take the supernatant (i.e. protein extract), and store at -50°C Vacuum freeze-drying under conditions for 72 hours to obtain protein freeze-dried powder for future use;

[0051] S2. Ultrasonic heating of β-carotene at 10 kHz and 50° C. for 20 minutes to dissolve it in corn oil, and prepare an oil phase with a mass concentration of β-carotene of 0.1% for use;

[0052] S3. Reconstitute the freeze-dried protein powder obtained in step S1 with pH 8, 10 mmol / L PBS, and prepare an aqueous phase with a protein concentration of 2 mg / mL for use;

[0053] S4. Mix the oil phase prepared in step S2 with the water phase prepared in step S3 in a ratio of 3:100 by weight, and disperse at a high speed of 10000r / min for 2min;

[0054] S5, 12000 psi high pressure homogenization 5 times to obta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com