High-speed dispersing device for fire retardant slurry

A high-speed dispersing device, flame retardant technology, applied in mixers with rotary stirring devices, transportation and packaging, dissolving and other directions, can solve the problems of long stirring time, poor stirring and dispersing effect, low stirring efficiency, etc. Good effect, improve stirring efficiency, protect the effect of rotating arm

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described below in conjunction with the accompanying drawings and embodiments, but not as a basis for limiting the present invention.

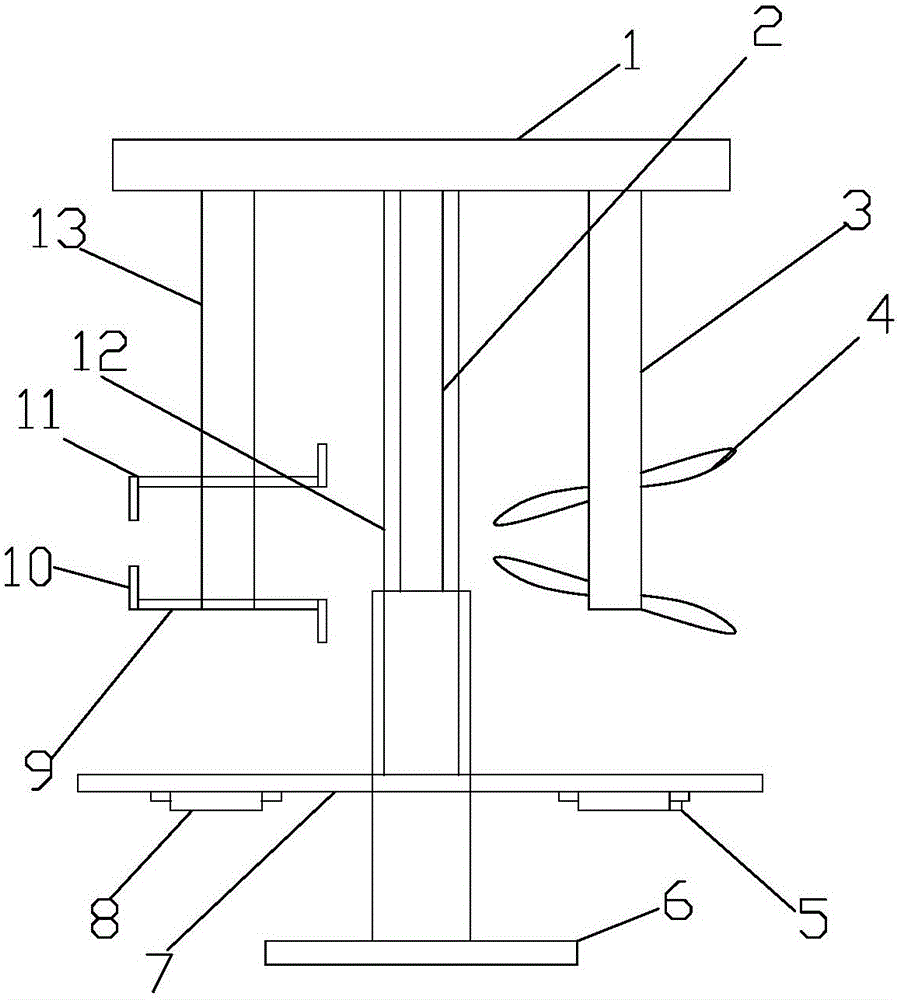

[0012] Example. A high-speed dispersion device for flame retardant slurry, consisting of figure 1 As shown, a base 6 is included, a hydraulic cylinder 2 is arranged on the base 6, a frame 1 is arranged on the hydraulic cylinder 2, and a left stirring shaft 13, a middle stirring shaft 12 and a right stirring shaft 3 arranged downward are arranged on the frame 1 , the bottom of the left stirring shaft 13 is provided with two stirring discs 11, the stirring disc 11 includes a disc 9, and the periphery of the disc 9 is provided with agitating blades 10 which are staggered up and down; the lower end of the middle stirring shaft 12 is provided with a rotating arm 7. The rotating arm 7 is provided with a rotating rod 8; the lower part of the right stirring shaft 3 is provided with two spiral stirring blad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com