Hydraulic machine

A technology for hydraulic presses and presses, applied in the field of hydraulic presses, can solve the problems of impeller and pump body collision and friction, stuck, parking, etc., and achieves the effect of improving inner hole accuracy, avoiding collision friction and stuck, and easy to use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

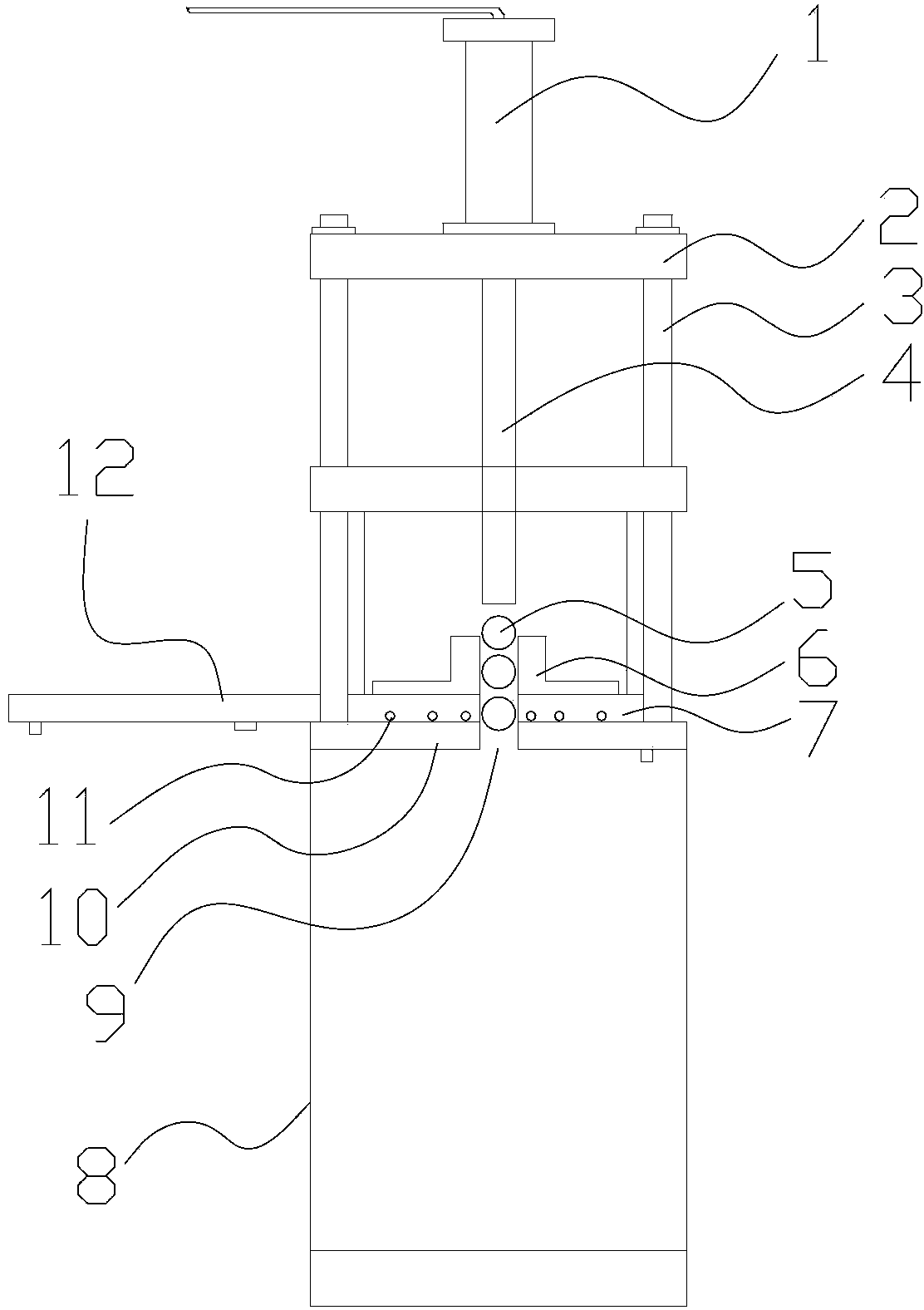

[0015] This embodiment relates to a hydraulic machine, such as figure 1 As shown, including: press 1, support 8, steel ball 5, base 7, lower support plate 10, the center of upper support plate 2, base 7 and support plate 10 is provided with through hole 9, and base 7 is provided with Fix the fixing bolt of the plastic impeller of the water pump of the automobile engine, the lower support plate 10 is arranged on the top of the support 8, the base 7 is arranged on the top of the lower support plate 10, and the centers of the base 7 and the lower support plate 10 are all provided with a through hole 9, and the upper The support plate 2 is fixed above the bracket 8 by the guide post 3, the guide post 3 is evenly distributed around, the base 7 and the lower support plate 10 are located between the upper support plate 2 and the bracket 8, and the top center of the upper support plate 2 A press 1 is provided, the output shaft of the press 1 is connected with a guide rod 4, and the gu...

Embodiment 2

[0017] This embodiment relates to a hydraulic machine, such as figure 1 As shown, including: press 1, support 8, steel ball 5, base 7, lower support plate 10, the center of upper support plate 2, base 7 and support plate 10 is provided with through hole 9, and base 7 is provided with Fix the fixing bolt of the plastic impeller of the water pump of the automobile engine, the lower support plate 10 is arranged on the top of the support 8, the base 7 is arranged on the top of the lower support plate 10, and the centers of the base 7 and the lower support plate 10 are all provided with a through hole 9, and the upper The support plate 2 is fixed above the bracket 8 by the guide post 3, the guide post 3 is evenly distributed around, the base 7 and the lower support plate 10 are located between the upper support plate 2 and the bracket 8, and the top center of the upper support plate 2 A press 1 is provided, the output shaft of the press 1 is connected with a guide rod 4, the guide ...

Embodiment 3

[0019] This embodiment relates to a hydraulic machine, such as figure 1 As shown, including: press 1, support 8, steel ball 5, base 7, lower support plate 10, the center of upper support plate 2, base 7 and support plate 10 is provided with through hole 9, and base 7 is provided with Fix the fixing bolt of the plastic impeller of the water pump of the automobile engine, the lower support plate 10 is arranged on the top of the support 8, the base 7 is arranged on the top of the lower support plate 10, and the centers of the base 7 and the lower support plate 10 are all provided with a through hole 9, and the upper The support plate 2 is fixed on the top of the support 8 by the guide post 3, the guide post 3 is evenly distributed around, the base 7 and the lower support plate 10 are located between the upper support plate 2 and the support 8, and the top center of the upper support plate 2 is provided with Press machine 1, the output shaft of press machine 1 is connected with gu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com