Pencil sharpener spiral hobbing cutter cold drawing production process method and mold

A spiral hob and production process technology, applied in forming tools, manufacturing tools, metal processing equipment, etc., can solve problems such as poor precision and complicated production process of spiral hob cold extrusion, and achieve improved precision and improved pencil sharpening life , good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] The cold-stretching production process of the spiral hob of the pencil sharpener and its mold adopt the following processing flow:

[0023] 1. Raw material drawing: draw the raw material into standard roundness;

[0024] 2. Cold heading processing: processing the drawn raw material into a single product with holes;

[0025] 3. Spheroidizing annealing: reduce the hardness of a single product with holes through spheroidizing annealing;

[0026] 4. Centerless grinding machine processing: grinding off the oxide skin on the surface of the spheroidized annealed product;

[0027] 5. Phosphorus saponification treatment: Phosphorus saponification on the surface of the product processed by centerless grinding, increasing surface lubrication and reducing friction with the mold;

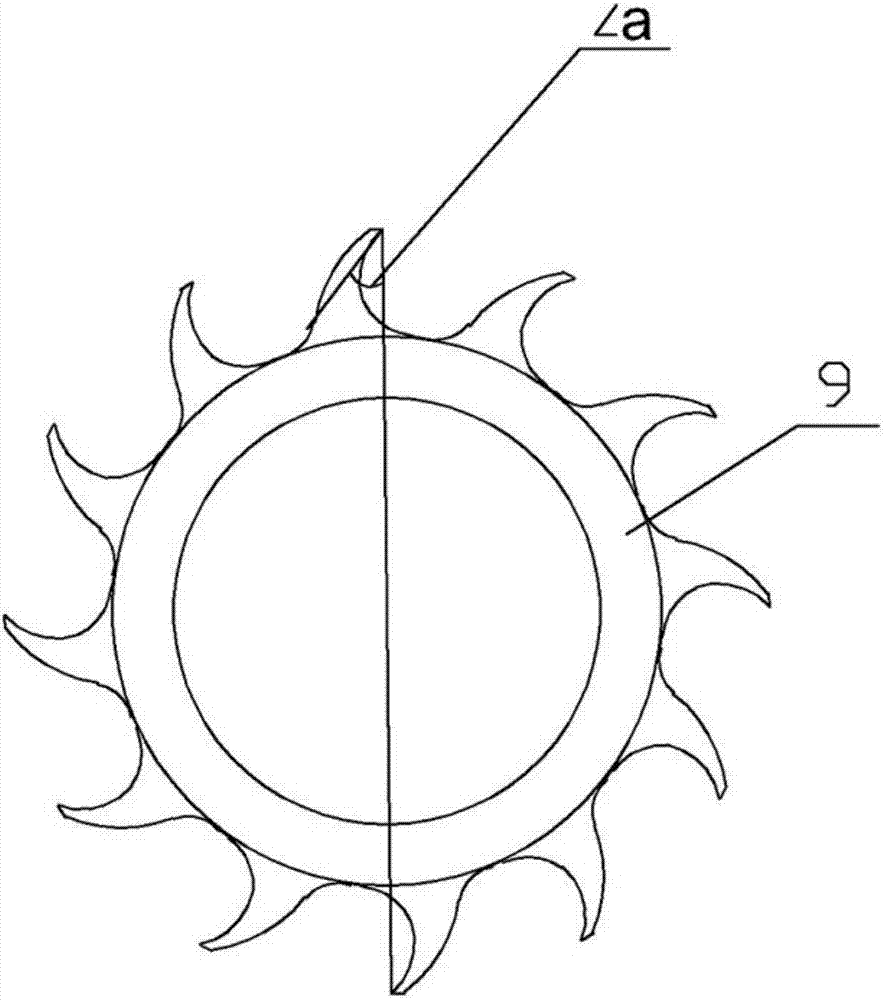

[0028] 6. Cold stretch processing: process the saponified product into a spiral hob 9 with a pre-made mold.

Embodiment 2

[0030] Production of cold drawing dies:

[0031] The raw materials are made of alloy materials, which are processed by spiral mirror pulses with pre-made electrodes, and then manually trimmed and polished at the feed port, and are matched at a high temperature of 800 degrees.

[0032] At present, ordinary machining cannot achieve a rake angle of more than 15 degrees, and only five-axis fine carving can be processed. However, considering that the cost of five-axis fine carving is very high, we use the five-axis fine carving process for electrode processing, and then process it well. The electrode is processed into a stretch forming mold by mirror spiral pulse, and the mold is polished and polished to form a good shape.

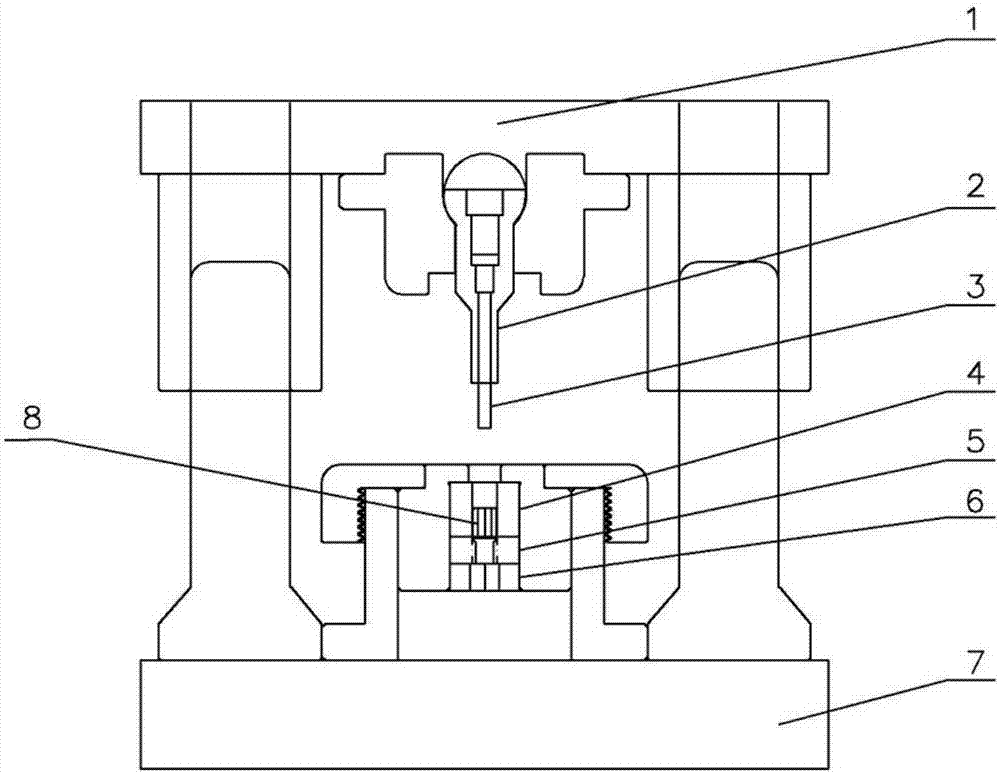

[0033] according to figure 1 , the mold structure includes an upper gland 1 and a lower base 7; a punch 2 and an inner hole core pulling 3 are arranged below the upper gland; a mold pad 6 is provided on the lower base; A molding die 5 is arranged on the upper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com