Tool for machining inner bore of rectangular cylinder by means of center lathe

A common lathe and rectangular technology, applied in metal processing equipment, metal processing machinery parts, positioning devices, etc., can solve the problems of high equipment purchase and maintenance costs, low processing efficiency, and low spindle speed of horizontal boring machines, and achieve Simple structure, improved processing efficiency and high precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

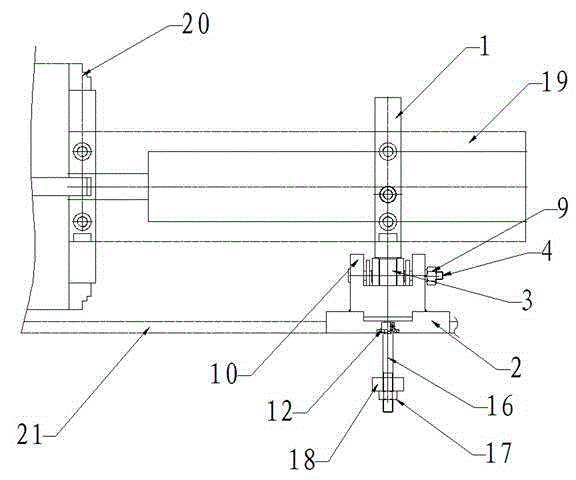

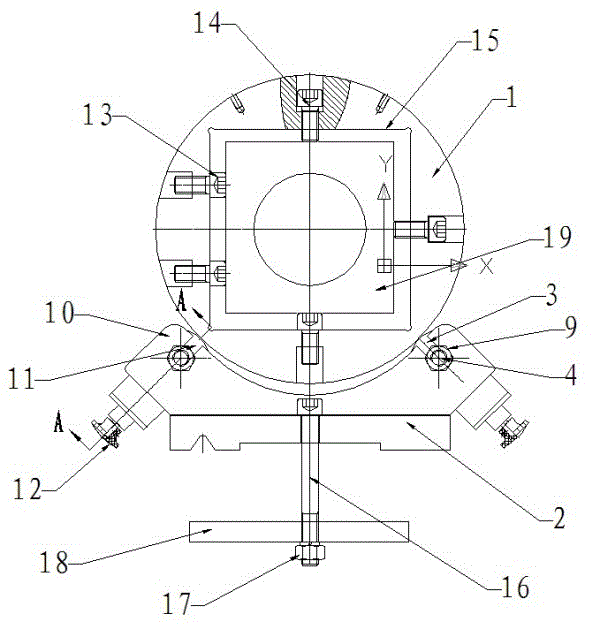

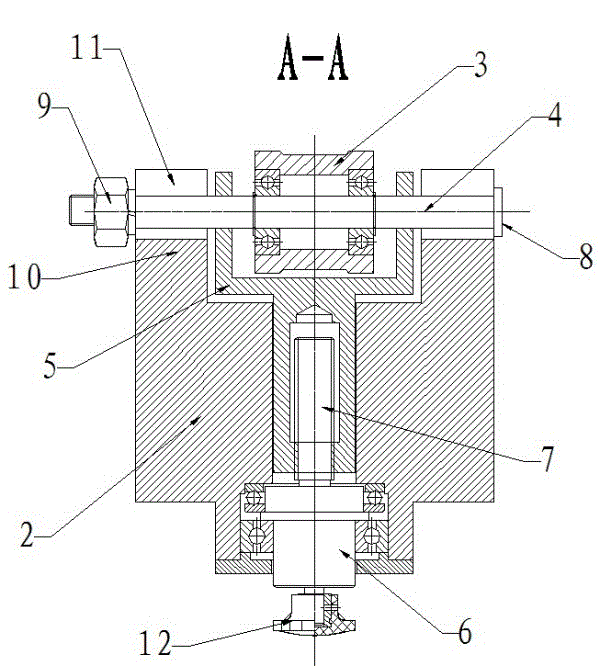

[0021] In order to clearly illustrate the technical features of this solution, the specific implementation of the present invention will be further described below according to the accompanying drawings.

[0022] like figure 1 , figure 2 and image 3 As shown, a tooling for machining the inner hole of a rectangular cylinder with an ordinary lathe includes a positioning clamping disc 1 and a roller support seat 2. There are two positioning clamping discs 1, and the positioning clamping disc 1 is provided with There is a positioning clamping mechanism, and the positioning clamping mechanism includes a positioning block 13, a jacking screw 14 and a rectangular inner hole 15 located at the center of the positioning clamping disc 1, and the side length of the rectangular inner hole 15 is 280 mm. , a positioning block 13 and two positioning blocks 13 are respectively provided on two adjacent planes of the rectangular inner hole 15, and the positioning block 13 is detachably mount...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com