Process method for manufacturing rotor shielding sleeve by mechanical processing

A technology of mechanical processing and process method, applied in the direction of manufacturing tools, metal processing, metal processing equipment, etc., can solve problems such as affecting the overall operation of the motor, large performance deviation, and difficult to control the welding quality of the rotor shielding sleeve.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

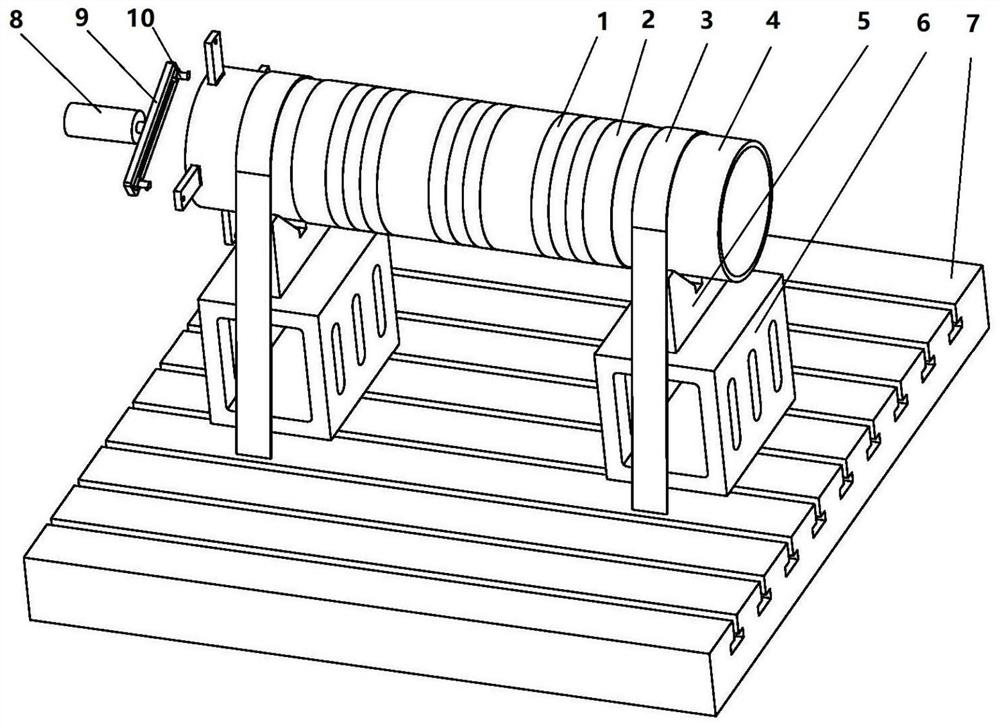

[0018] Such as figure 1 As shown, a process method for manufacturing a rotor shielding sleeve by mechanical processing includes the following steps:

[0019] 1) Clean the workbench 7 of the boring machine to ensure the cleanliness of the workbench;

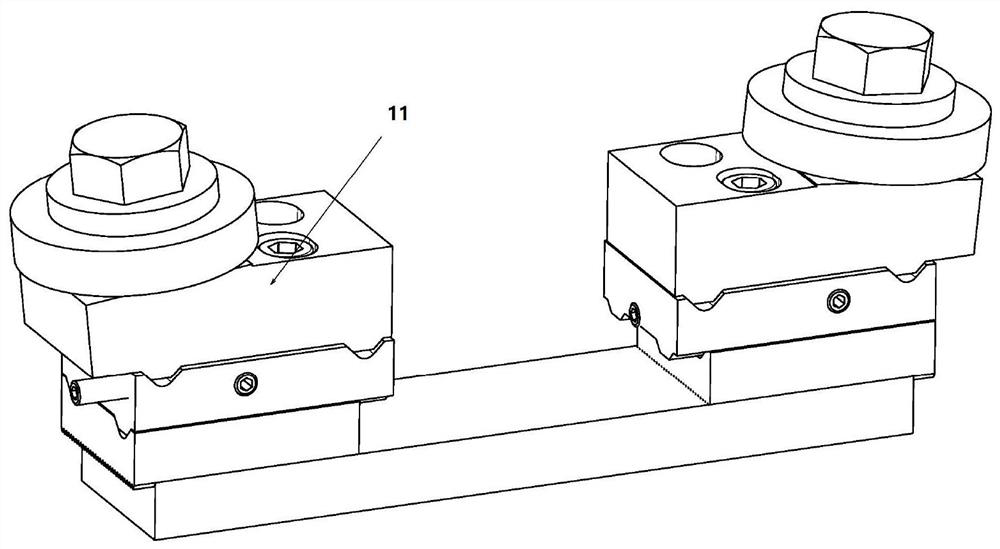

[0020] 2) Install the square box 6 on the workbench 7 respectively, install the V-shaped iron 5 on the square box, and adjust the level of the V-shaped iron 5 with a spirit level, and the parallelism of the V-shaped iron 5 relative to the workbench 7 is not greater than 0.02mm;

[0021] 3) Install the rotor shielding sleeve 4 horizontally on the V-shaped iron 5. The outer surface of the rotor shielding sleeve 4 is wrapped with a 3mm thick oil-resistant rubber plate 2 for reducing vibration during processing. The tape 1 fixes the rotor shielding sleeve 4 and the oil-resistant rubber plate 2. The two ends of the rotor shielding sleeve 4 are wound with shrinkage tape 3 at a position 200 mm away from the end face, and the shrinkage t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com