Pipe cutting machine

A pipe cutting machine and pipe cutting technology, which is applied in the direction of pipe shearing device, shearing device, shearing machine equipment, etc., can solve the problems of high labor intensity, accident risk, and expensive equipment for hacksaw cutting, and achieve high production efficiency and avoid The effect of collision friction and low manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

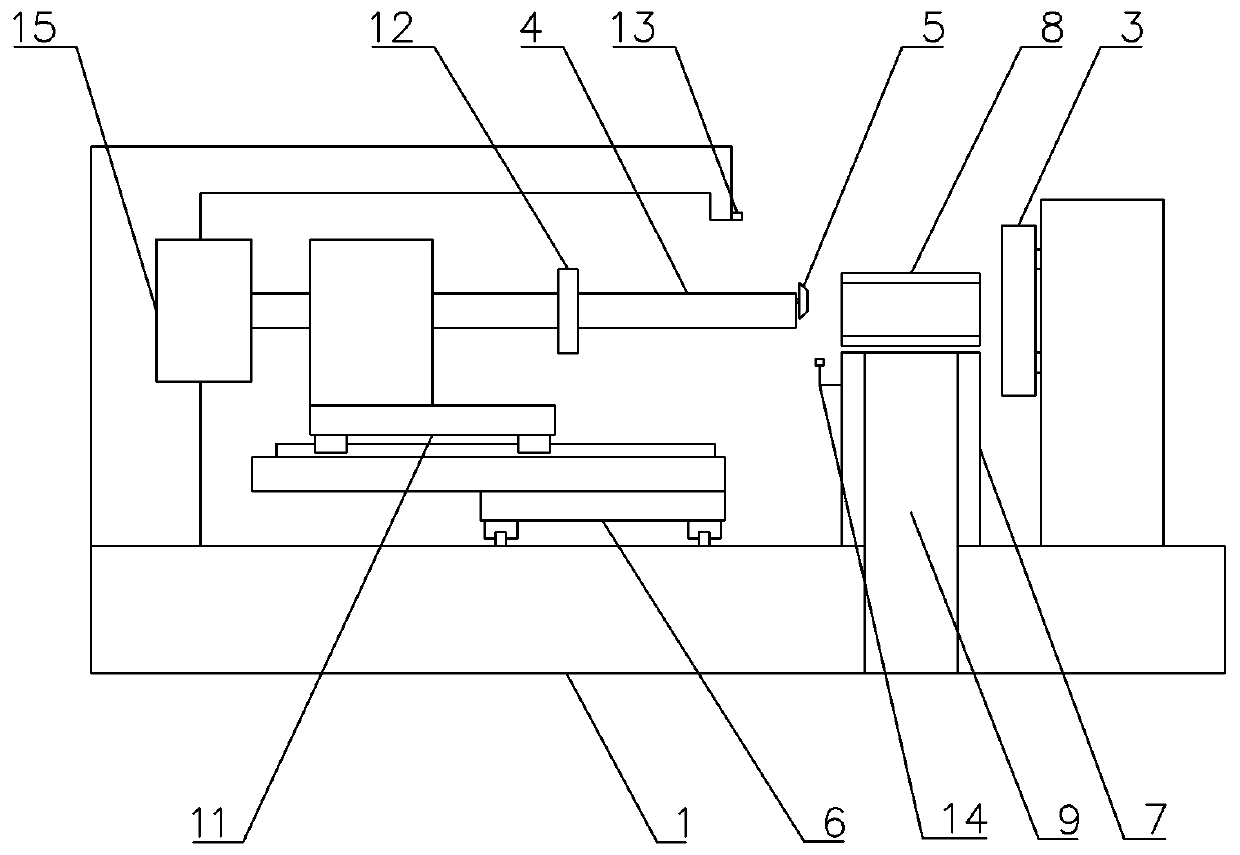

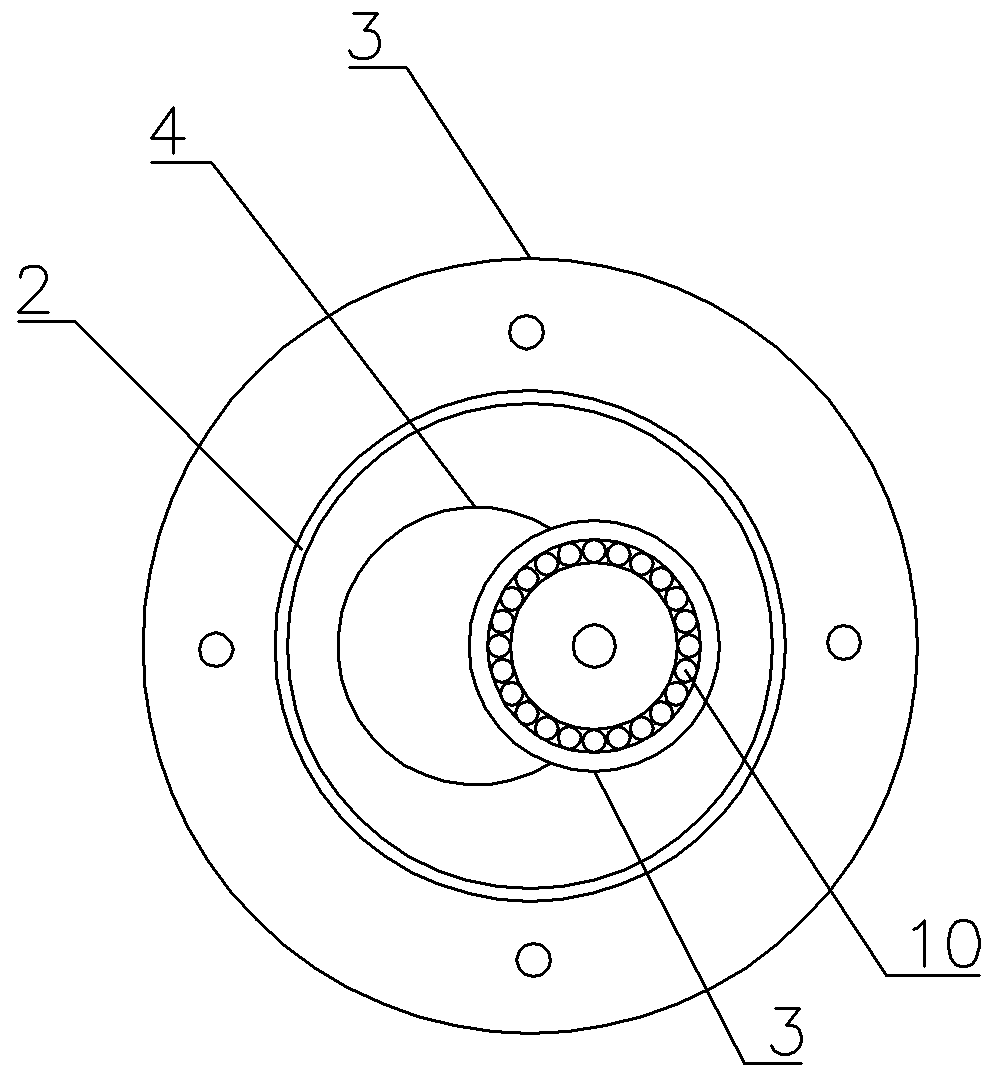

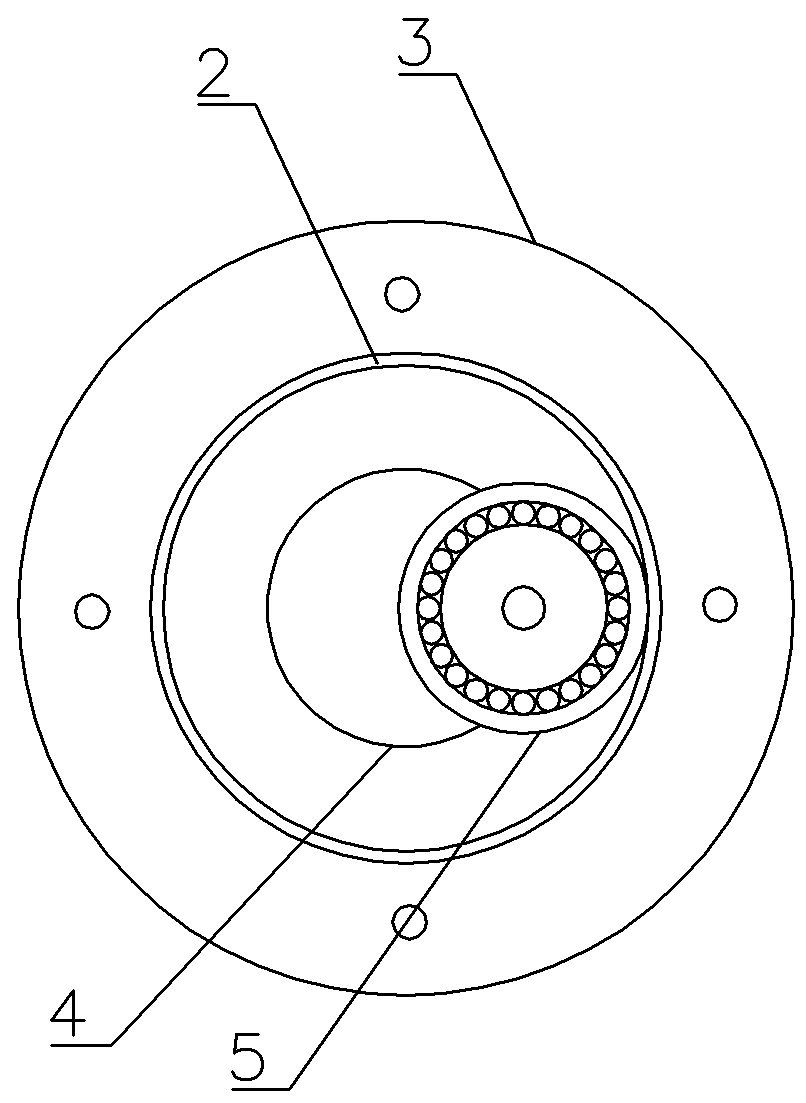

[0021] refer to Figure 1 to Figure 3 As shown, the pipe cutting machine includes a frame 1, and the frame 1 is provided with an outer cutter cylinder 3 and an inner cutter assembly for cutting the pipe material 2, and the pipe material 2 is placed in the outer cutter cylinder 3, so that The inner cutter assembly includes a rotating shaft 4 and an eccentric cutter 5 eccentrically mounted on one end of the rotating shaft 4, and the rotating shaft 4 drives the eccentric cutter 5 to rotate; the inner cutter assembly is provided with a Y-axis displacement mechanism 6, and the inner cutter assembly The Y-axis displacement mechanism 6 drives the rotating shaft 4 to move radially inside the pipe 2; during processing, the axis of the cutter shaft is concentric with the axis of the pipe 2, and the eccentric cutter 5 is close to the inner wall of the pipe 2. The radial displacement of the rotating shaft 4 and the eccentric cutter 5 is controlled by the Y-axis displacement mechanism 6; d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com