One-component high-elasticity silylated polyurethane waterproof coating and production method thereof

A technology of silanized polyurethane and waterproof coatings, which is applied in the direction of polyurea/polyurethane coatings and coatings, which can solve the problems of weak bonding of inorganic materials, unfriendly environment, and long curing time, so as to shorten the curing time and facilitate construction , enhance the effect of bonding performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] The one-component highly elastic silylated polyurethane waterproof coating is prepared from the following raw materials in parts by weight:

[0025] 50-70 parts of polyether polyol (330N), 180-200 parts of polyether polyol (DDL-2000), 60-70 parts of diphenylmethane diisocyanate (MDI), 10-20 parts of toughening agent minus four lines Oil, 10-15 parts of silane coupling agent (KH-590), 0.3-0.5 parts of catalyst (T-12), 3-5 parts of latent curing agent, 5-7 parts of epoxy resin, 20-30 parts of non-reactive dilution Agent, 140-180 parts of powdered filler, 3-5 parts of white carbon black, 3-5 parts of carbon black, 0.3 parts of antioxidant.

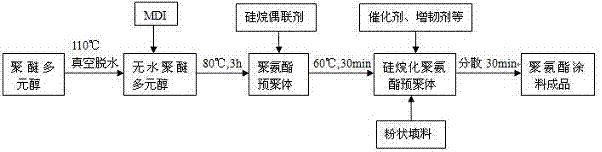

[0026] The preparation method of the above-mentioned one-component highly elastic silylated polyurethane waterproof coating comprises the following steps:

[0027] (1) Configure each component according to the above weight ratio, and dehydrate polyether polyol (330N) and polyether polyol (DDL-2000) by heating to form anhydrous polyeth...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com