Corn starch composite membrane as well as preparation method and applications thereof

A corn starch, waxy corn starch technology, applied in climate change adaptation, sustainable manufacturing/processing, flexible covering, etc. The effect of good social and economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0065] Weigh 7.5g of cornstarch and 3g of glycerol, add them into a beaker filled with 100mL of distilled water, and mix different contents of nano-CaCO 3 Add 50mL of distilled water for ultrasonic dispersion, then mix with the mixture of starch and glycerol, heat in a boiling water bath until the starch is completely gelatinized, stir magnetically for 30 minutes, degas for about 15 minutes, pipette a certain amount of film liquid to make a film, and heat at 45°C Dry for 48 hours in a blower drier, remove the film, and store in a desiccator with a relative humidity (67%).

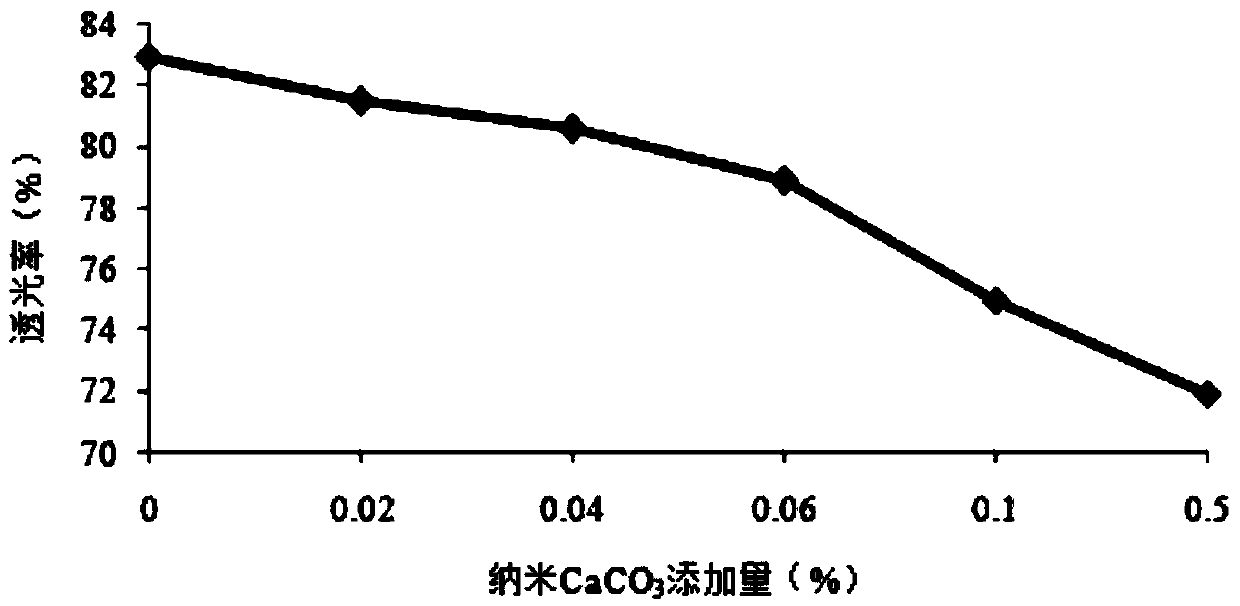

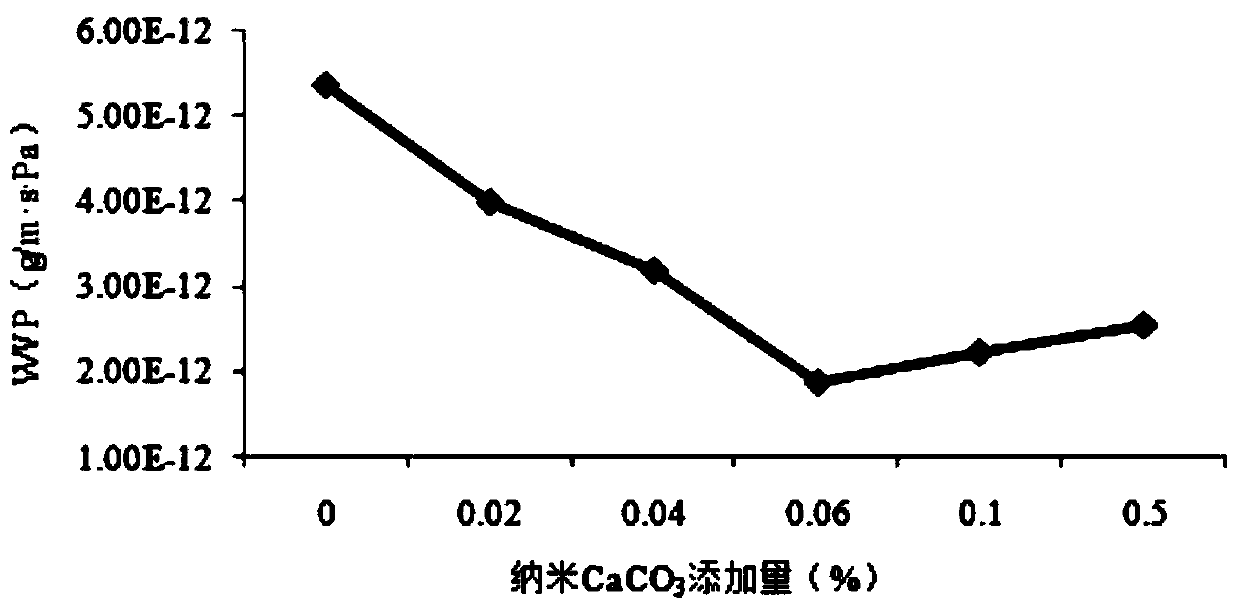

[0066] Configure Nano CaCO 3 The mass fractions of content in each film are 0%, 0.02%, 0.04%, 0.06%, 0.1%, 0.5% (nano CaCO 3 quality / quality of cornstarch).

[0067] Table 1 Nano-CaCO 3 Effect of Content on Mechanical Properties of Corn Starch Films

[0068]

[0069]

[0070] Note: The values in the table are expressed as mean ± standard deviation; 2) Different letters after the mean value in ea...

Embodiment 2

[0093] Weigh 7.5g of cornstarch and 3g of glycerin, add them into a beaker filled with 100mL of distilled water, add different amounts of waxy cornstarch nanoparticles into 50mL of distilled water for ultrasonic dispersion, then mix them with the mixture of starch and glycerol, and place in a boiling water bath Heat in medium until the starch is completely gelatinized, stir magnetically for 30 minutes, degas for about 15 minutes, pipette a certain amount of film liquid to form a film, dry it in a blast dryer at 45°C for 48 hours, peel off the film, and store it at a relative humidity (67%) Store in a desiccator.

[0094] The mass fractions of starch nanoparticle content in each film were configured to be 0%, 1%, 5%, 15%, 20%, 25% (mass of starch nanoparticle / mass of cornstarch).

[0095] Table 4 Effect of waxy corn starch nanoparticles content on mechanical properties of corn starch films

[0096]

[0097] Note: The values in the table are expressed as mean ± standard de...

Embodiment 3

[0116] Weigh 0.06% (accounting for starch dry basis) nano-CaCO 3 , add 100mL of distilled water for ultrasonic dispersion, add 7.5g of cornstarch and 3g of glycerin, heat in a boiling water bath until the starch is completely gelatinized, and after magnetic stirring for 30min, add different amounts of chitosan acetic acid solution into the cooled In the gelatinized liquid, stir magnetically for 30 minutes after mixing, then degas for about 15 minutes, pipette a certain amount of film liquid to form a film, dry it in a blast dryer at 45°C for 48 hours, peel off the film, and dry at a relative humidity (67%) save in the device.

[0117] Dissolve chitosan with different contents in 50ml concentration of 1% acetic acid solution, mix well, set aside.

[0118] The mass fractions of chitosan content in each film were configured to be 0%, 10%, 20%, 30%, 40%, 50% (mass of chitosan / mass of cornstarch).

[0119] (Escherichia coli ATCC 25922 Shanghai Fuxiang Biotechnology Co., Ltd.)

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com