Polymer composite material containing micro-nano hybrid structure filler, and preparation method thereof

A technology of composite materials and structural fillers, applied in heat exchange materials, chemical instruments and methods, polycrystalline material growth, etc., can solve the problem of damage to polymer matrix processing performance, uneven distribution of whisker diameter, and reduction of aspect ratio, etc. problems, to achieve the effects of improving comprehensive mechanical properties, good reinforcement and toughening effect, high melt index and melt strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

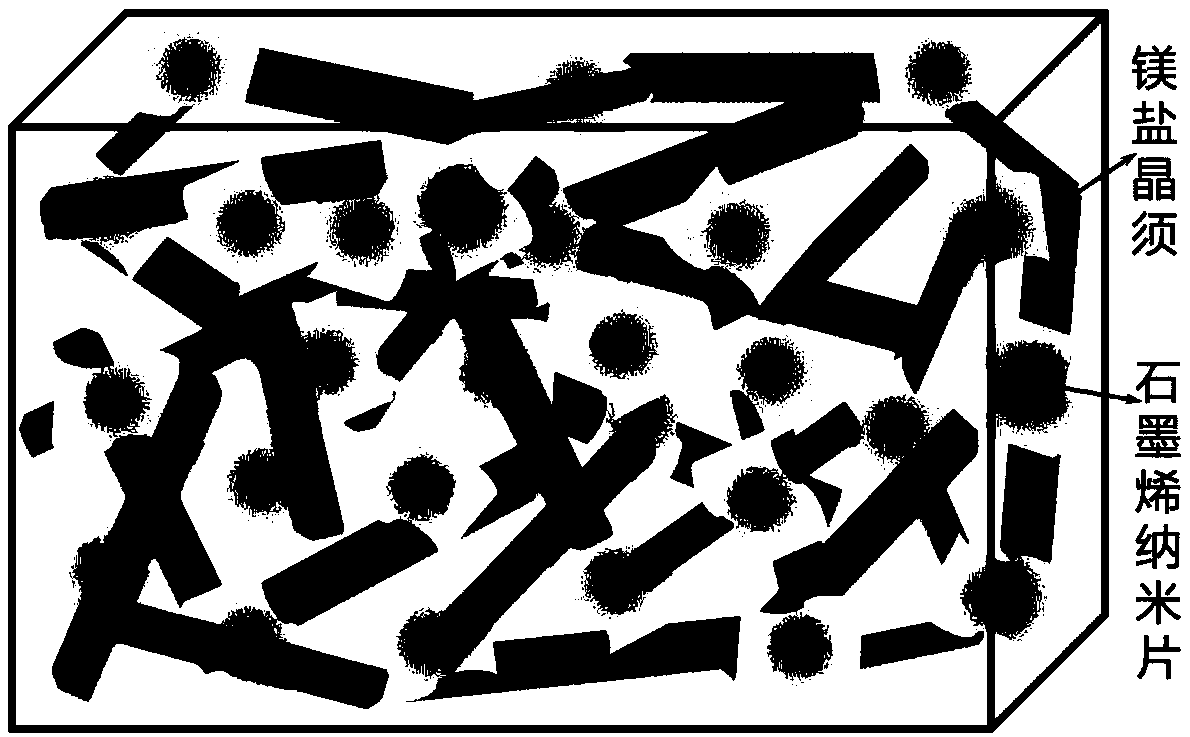

[0059] A preparation method of a polymer composite material containing a micro-nano hybrid structure filler, comprising the following steps:

[0060] Dissolve an appropriate amount of soluble carbonate or alkali and stabilizer in water, and stir evenly to obtain mixed solution A; at the same time, dissolve soluble magnesium salt in water, and stir uniformly to obtain solution B; add B evenly into A under normal temperature stirring state to obtain The uniform mixed solution C is left standing after mixing, and the insoluble magnesium salt crystals nucleate, grow, and precipitate, and after separation and drying, white magnesium carbonate whiskers or flocculent precipitates of magnesium hydroxide whiskers are obtained;

[0061] Stabilizer used in the present invention is one or more in polyethylene glycol, sodium dodecylbenzenesulfonate, fatty acid glyceride, polyethylene glycol p-isooctylphenyl ether or carboxymethyl cellulose, so The mass ratio of the stabilizer to water is 0...

Embodiment 1

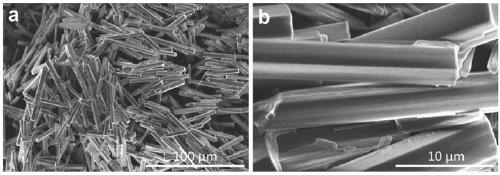

[0075] Dissolve 5kg of sodium carbonate and 50g of polyethylene glycol p-isooctyl phenyl ether in 50kg of water, stir well to obtain mixed solution A; at the same time, dissolve 4.5kg of magnesium chloride in 50kg of water, stir well to obtain solution B; B was evenly added to A to obtain a uniform mixed solution C, which was left to stand at 25°C for 6 hours after mixing to obtain flocculent precipitates of white magnesium carbonate whiskers.

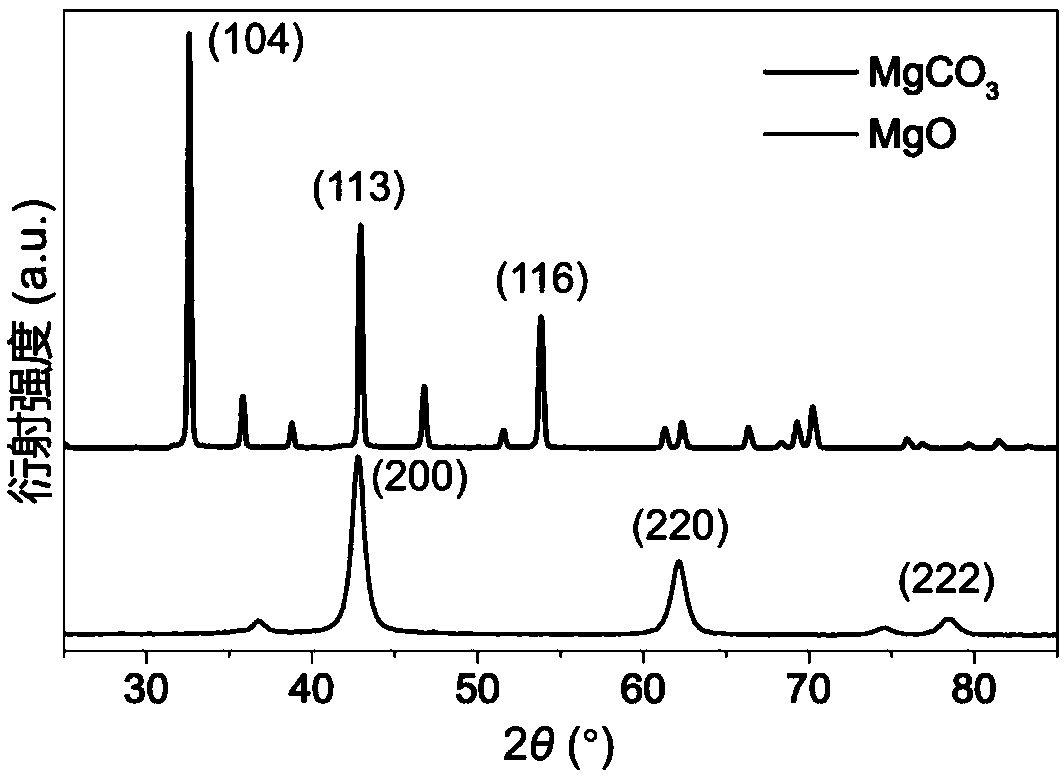

[0076] Centrifuge and dry the magnesium carbonate whisker precipitate, and calcinate at 700°C for 0.5 hours to remove free water, bound water and CO 2 molecules, resulting in white fluffy magnesium oxide whiskers.

[0077] After mixing 1 part of graphene nanosheets and 20 parts of magnesium oxide whiskers with 79 parts of polyethylene (PE), melt and mix them through a twin-screw extruder, extrude and granulate to obtain a PE composite material.

Embodiment 2

[0079] Dissolve 53kg of sodium carbonate and 5kg of carboxymethyl cellulose in 50kg of water, and stir evenly to obtain a mixed solution A; at the same time, dissolve 59.2kg of magnesium nitrate in 50kg of water, and stir evenly to obtain a solution B; add B evenly to A under stirring at room temperature , a uniform mixed solution C was obtained, and after mixing, it was left to stand at 20° C. for 12 hours to obtain flocculent precipitates of white magnesium carbonate whiskers.

[0080] Centrifuge and dry the magnesium carbonate whisker precipitate, and calcinate at 500°C for 6 hours to remove free water, bound water and CO 2 molecules, resulting in white fluffy magnesium oxide whiskers.

[0081] After mixing 10 parts of graphene nanosheets and 1 part of magnesium oxide whiskers with 89 parts of polypropylene (PP), melt and mix them through a twin-screw extruder, extrude and granulate to obtain a PP composite material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com