Polyvinyl alcohol fiber dispersion technology and application thereof

A polyvinyl alcohol fiber and dispersion technology, which is applied in the field of materials, can solve problems such as poor dispersion, and achieve the effect of simple technology, easy control, and improved dispersion uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] 1. Use graphene powder to disperse polyvinyl alcohol fibers, the specific steps are as follows:

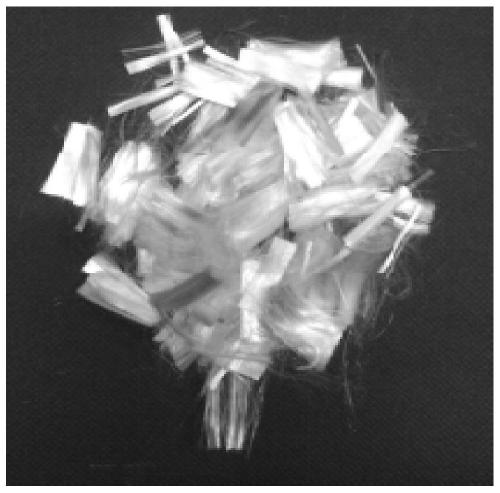

[0027] (1) 1g polyvinyl alcohol fiber (its initial product state is as figure 1 As shown, it is a bundle) placed in a glass container, stirred at 5°C for 120s, the bundle fiber becomes fluffy (such as figure 2 shown).

[0028] (2) Add 0.1g of graphene powder with a particle size of 5 to 50 microns to the polyvinyl alcohol fiber in step (1), then put the mixture together in a ball mill, stir for 120s, and the fluffy fiber is dispersed into a monofilament (Such as image 3 As shown), the polyvinyl alcohol fiber is dispersed, and finally a monofilament polyvinyl alcohol fiber is obtained.

[0029] Two, the monofilament polyvinyl alcohol fiber obtained above is applied to the preparation of concrete materials, according to the following steps:

[0030] (1) Determine the amount of cement, water, sand, aggregate and monofilament polyvinyl alcohol fiber according to the concr...

Embodiment 2

[0036] Using graphene powder to disperse polyvinyl alcohol fibers, the specific steps are as follows:

[0037] (1) Put 1 g of polyvinyl alcohol fibers in a glass container, stir at 35°C for 150 s, and the bundled fibers will become fluffy fibers.

[0038] (2) Add 0.2g of graphene powder with a particle size of 5 to 50 microns to the polyvinyl alcohol fiber in step (1), then put the mixture together in a ball mill, stir for 120s, and the fluffy fiber is dispersed into a monofilament , the polyvinyl alcohol fibers are dispersed, and finally monofilament polyvinyl alcohol fibers are obtained.

[0039] According to the method of Example 1, the monofilament polyvinyl alcohol fibers were applied to the preparation of concrete materials, and the results showed that the monofilament polyvinyl alcohol fibers obtained in this embodiment could be well dispersed in the concrete.

Embodiment 3

[0041] Using graphene powder to disperse polyvinyl alcohol fibers, the specific steps are as follows:

[0042] (1) Put 1 g of polyvinyl alcohol fibers in a glass container, stir at 50°C for 180 s, and the bundled fibers become fluffy.

[0043] (2) Add 0.2g of graphene powder with a particle size of 5 to 50 microns to the polyvinyl alcohol fiber in step (1), then put the mixture together in a ball mill, stir for 120s, and the fluffy fiber is dispersed into a monofilament , the polyvinyl alcohol fibers are dispersed, and finally monofilament polyvinyl alcohol fibers are obtained.

[0044] According to the method of Example 1, the monofilament polyvinyl alcohol fibers were applied to the preparation of concrete materials, and the results showed that the monofilament polyvinyl alcohol fibers obtained in this embodiment could be well dispersed in the concrete.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com