High-tenacity high-anti-permeability high-durability concrete and preparation method thereof

A durable concrete and high-toughness technology, applied in the field of building materials, can solve the problems that the compressive strength is easy to achieve, the flexural strength, splitting tensile strength, flexural strength and anti-penetration are difficult to achieve and other durability indicators, so as to improve Thermal conductivity, uniform micro- and macro-structure, improved crack resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

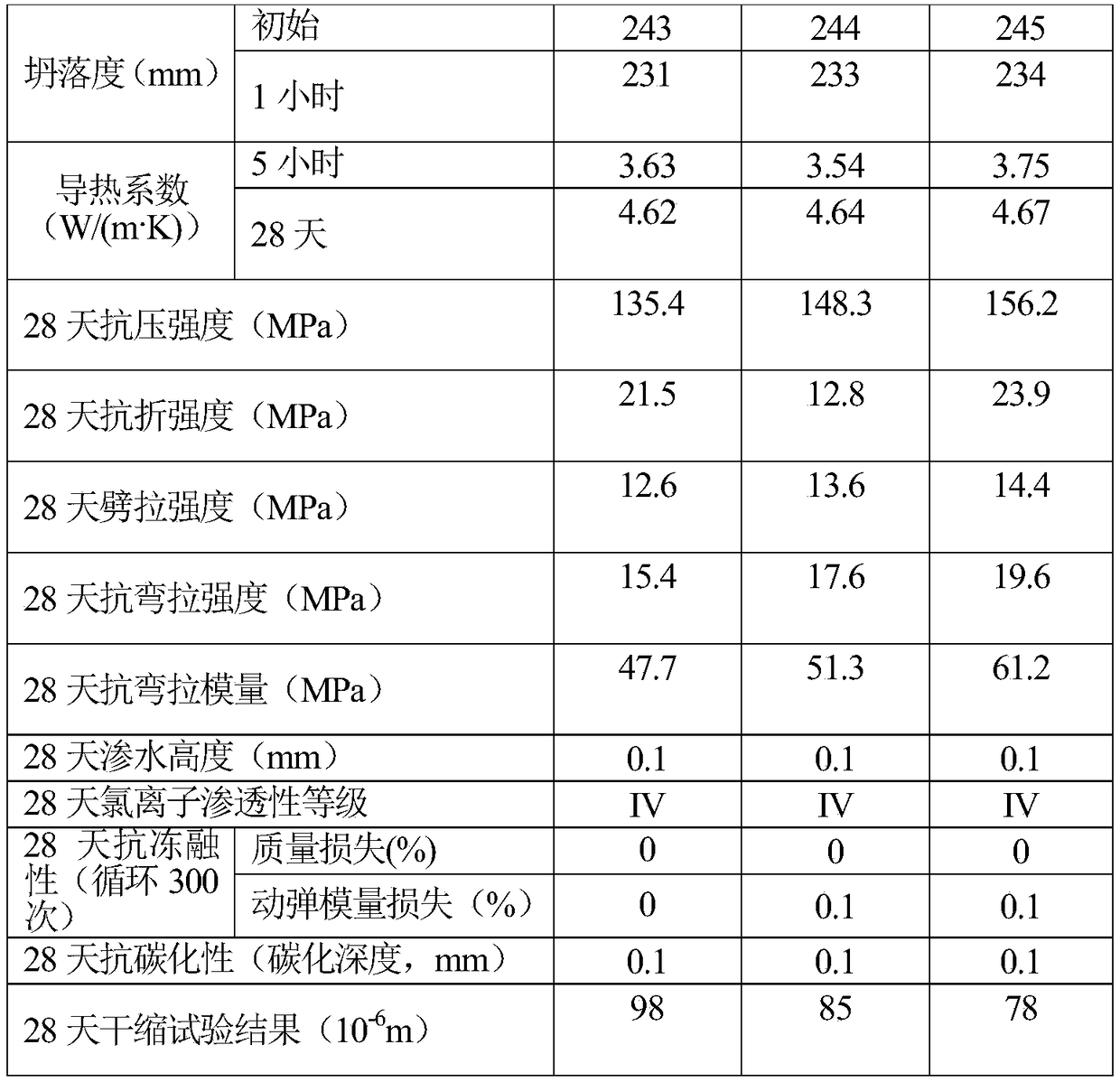

[0041] Example 1: Preparation method of C130 high toughness, high impermeability and high durability concrete

[0042] Step 1, put 980 parts of crushed stone, 505 parts of sand, 40 parts of silicon powder, 34 parts of boron nitride powder, 0.5 part of low-degree graphene oxide sheet powder, and 1.4 parts of high-strength polyvinyl alcohol fiber into the Into the mixer to make it fully mixed;

[0043] Step 2, adding 418 parts of cement, 34 parts of fly ash, 45 parts of steel slag powder and 17 parts of phosphorus slag powder into the mixture of step 1 in order to make it evenly mixed by mass parts;

[0044] Step 3: Mix 11.7 parts of dispersing activator, 17.6 parts of water reducing agent, 117.2 parts of modified graphene oxide dispersion liquid and 47.2 parts of water according to parts by mass and stir evenly to obtain a mixture;

[0045] Step 4: Slowly add the mixture prepared in Step 3 to the mixture prepared in Step 2 under stirring to obtain high-toughness, high-impermea...

Embodiment 2

[0067] Example 2: Preparation method of C140 high toughness, high impermeability and high durability concrete

[0068] Step 1, put 960 parts of crushed stone, 473 parts of sand, 40 parts of silicon powder, 35 parts of boron nitride powder, 0.7 part of low-degree graphene oxide sheet powder, and 1.5 parts of high-strength polyvinyl alcohol fiber into the Into the mixer to make it fully mixed;

[0069] In step 2, 425 parts of cement, 35 parts of fly ash, 47 parts of steel slag powder and 17 parts of phosphorus slag powder are added to the mixture of step 1 in turn and stirred to make it evenly mixed according to the number of parts by mass;

[0070] Step 3: Mix 12 parts of dispersing activator, 17.9 parts of water reducer, 119.6 parts of modified graphene oxide dispersion and 44.6 parts of water according to parts by mass and stir to obtain a mixture;

[0071] Step 4: Slowly add the mixture prepared in Step 3 to the mixture prepared in Step 2 under stirring to obtain high-tough...

Embodiment 3

[0073] Example 3: Preparation method of C150 high toughness, high impermeability and high durability concrete

[0074] Step 1, put 900 parts of gravel, 443 parts of sand, 41 parts of silicon powder, 37 parts of boron nitride powder, 1.0 parts of low-degree graphene oxide sheet powder, and 1.6 parts of high-strength polyvinyl alcohol fiber according to the number of parts by mass. Into the mixer to make it fully mixed;

[0075] Step 2, adding 432 parts of cement, 35 parts of fly ash, 49 parts of steel slag powder and 18 parts of phosphorous slag powder into the mixture of step 1 successively by mass parts and stirring to make it evenly mixed;

[0076] Step 3: Mix 12.2 parts of dispersing activator, 18.3 parts of water reducing agent, 122.2 parts of modified graphene oxide dispersion liquid and 36.7 parts of water according to parts by mass and stir evenly to obtain a mixture;

[0077] Step 4: Slowly add the mixture prepared in Step 3 to the mixture prepared in Step 2 under sti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com