Size distribution method for micro powder

An ultra-fine powder and dispersion technology, which is applied in the direction of mixing methods, chemical instruments and methods, and dissolution, can solve the problems of secondary agglomeration, enlargement of inorganic material powder particles, and high cost of material powder to achieve dispersion modification Good effect and cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Theoretical analysis and mathematical derivation of the ultrafine powder gradation dispersion method of the present invention.

[0019] The spatial geometry of the interstices of a particle affects its overall filling characteristics to varying degrees, depending on factors such as filling type, particle shape, and particle size distribution.

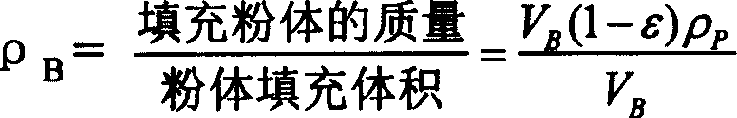

[0020] (1) Bulk density ρ B It is the mass of powder per unit filling volume in a certain filling state, also known as apparent density, and the unit is kg / m 3 .

[0021] formula:

[0022]

[0023] Where: V B —Powder filling volume, m 3 ;

[0024] ρ P —The density of particles Kg / m 3 ;

[0025] ε—porosity;

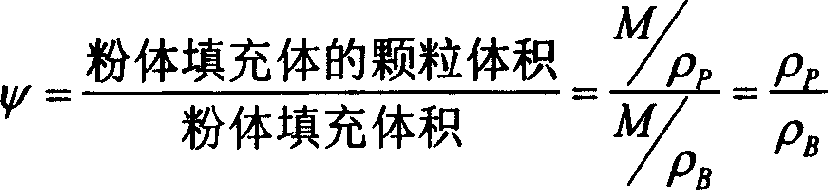

[0026] (2) The filling rate ψ is the ratio of the particle volume to the powder volume under a certain filling state.

[0027] formula:

[0028]

[0029] In the formula: M—mass of filling powder.

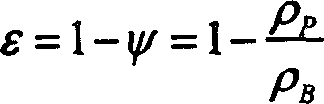

[0030] (3) Porosity ε is the ratio of void volume to powder filling volume.

[0031] formula:

[0032] ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com