Heat resistant and corrosion resistant vermicular cast iron material and preparation method thereof

A technology of vermicular graphite cast iron and corrosion resistance, which is applied in the field of heat-resistant and corrosion-resistant vermicular graphite cast iron materials and their preparation, can solve the problems affecting the heat resistance, heat and corrosion resistance, and limited toughness of materials, so as to improve the heat resistance and corrosion resistance. Corrosion, low production cost and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

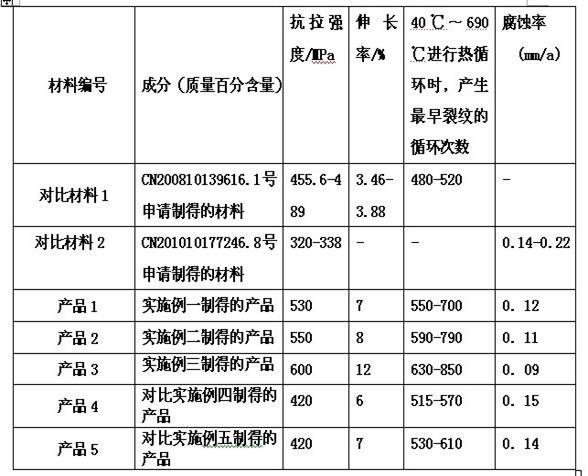

Embodiment 1

[0028] Composition of compacted graphite iron material matrix:

[0029] Preparation of chrome-plated iron wire and cobalt-plated iron wire: Take the iron wire with a diameter of 1mm and the composition weight percentage: C is 0.05%, Si is 0.2%, Mn is 0.40%, P<0.02%, S<0.025%, and the rest is Fe . Iron wire accounts for 5% of the volume of the material.

[0030] Chromium-plating on the surface of half of the iron wire and cobalt-plating on the other half of the iron wire according to conventional methods; respectively form chrome-plated iron wire and cobalt-plated iron wire, the thickness of the chromium-plated and cobalt-plated layers is 100 μm, and the overall length of the formed chromium-plated iron wire and cobalt-plated iron wire is equivalent;

[0031] According to the conventional method of cleaning ball production, each of the above-mentioned chrome-plated iron wire and cobalt-plated iron wire takes one wire to form a spherical mixed double-wire wire group (two wires...

Embodiment 2

[0035] The matrix composition of vermicular graphite cast iron material is by weight percentage: C is 3.5%, Si is 3.9%, Mn is 0.4%, Dy is 0.7%, Zr is 0.7%, P<0.03%, S <0.025%, and the rest is Fe for batching .

[0036] The weight percentage of iron wire components is: C is 0.07%, Si is 0.3%, Mn is 0.45%, P<0.02%, S<0.025%, and the rest is Fe. The wire diameter is 2mm. Iron wire accounts for 40% of the volume of the material.

[0037] Chromium-plated on the surface of half of the iron wire, and cobalt-plated on the surface of the other half of the iron wire according to the conventional method; the chrome-plated iron wire and the cobalt-plated iron wire were formed respectively, the thickness of the chrome-plated and cobalt-plated layers were both 500 μm, and the overall length of the two was equivalent. The conventional method that cleaning ball is produced makes the double-wire wire group that two kinds of metal wires of band plating mix, and the wire group diameter is 10cm...

Embodiment 3

[0040] The matrix composition of vermicular graphite cast iron material is by weight percentage: C is 3.4%, Si is 3.8%, Mn is 0.13%, Dy is 0.45%, Zr is 0.6%, P<0.03%, S <0.025%, and the rest is Fe.

[0041] The weight percentage of iron wire components is: C is 0.06%, Si is 0.25%, Mn is 0.43%, P<0.02%, S<0.025%, and the rest is Fe. The wire diameter is 1.5mm. Iron wire accounts for 20% of the volume of the material.

[0042] According to the conventional method, half of the iron wire surface is chrome-plated, and the other half of the iron wire surface is cobalt-plated; the chrome-plated iron wire and the cobalt-plated iron wire are respectively formed. The conventional method that cleaning ball is produced makes the two-wire metal wire group that two kinds of metal wires of band plating mix, and the wire group diameter is 15cm.

[0043] During the preparation, 0.7% of the molten iron mass 75 ferrosilicon inoculant and 0.5% of the Dy-containing rare earth vermicular agent we...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com