Spinning and drawing process of fixing metal film casing for printer and duplicator and the locking fixture therefor

A technology of copiers and printers, applied in the field of precision machining, to achieve the effects of long service life, high surface roughness, and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

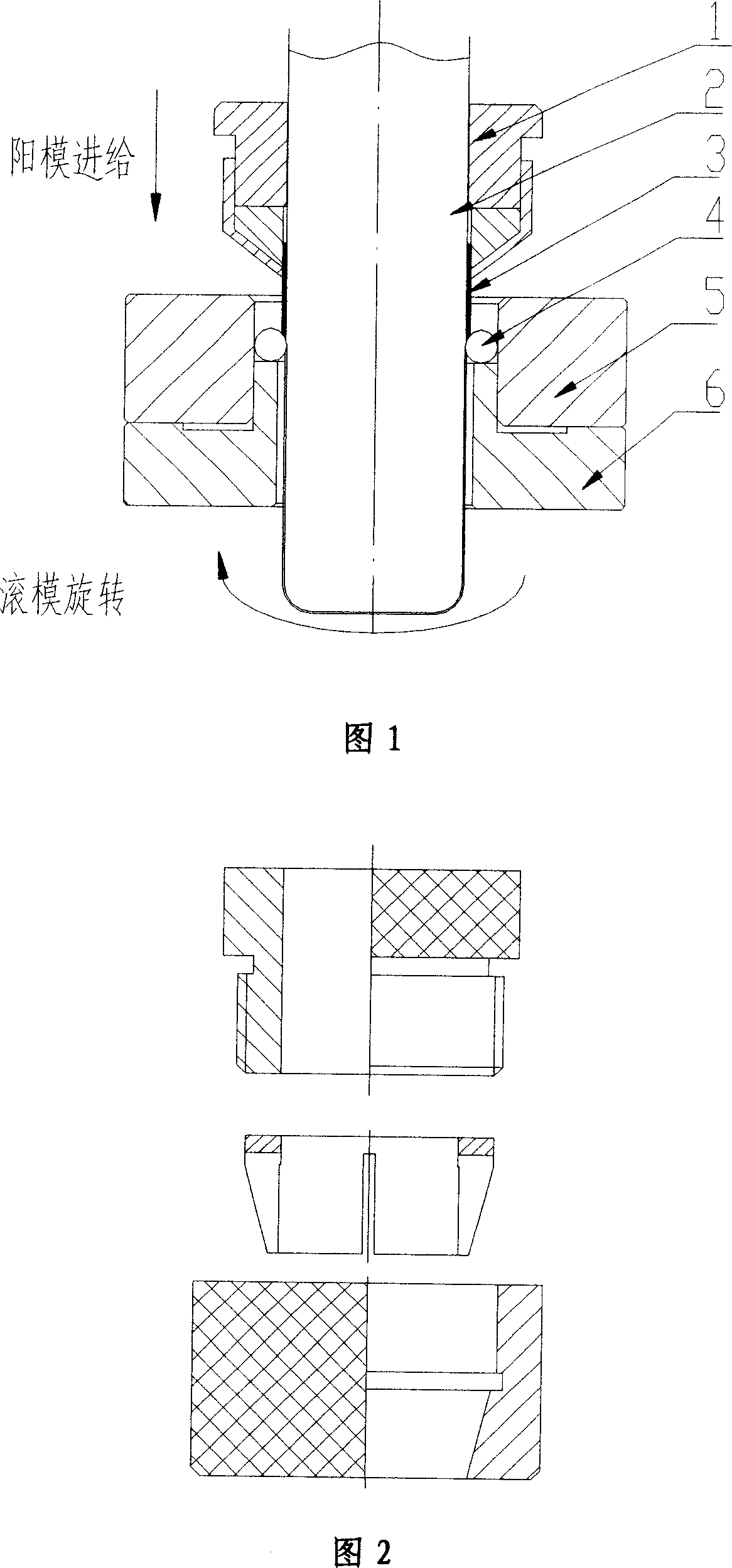

[0046] Spinning stretching parameters used:

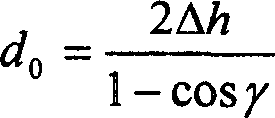

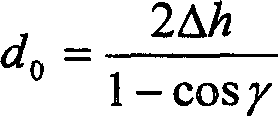

[0047] Thinning Δh and deformation ε: Δh=0.185; ε=0.82;

[0048] Bite angle γ: take 21°;

[0049] The diameter and quantity of the steel ball: the calculated diameter of the steel ball is φ5.6; the diameter of the steel ball is φ5;

[0050] The rotation speed of the roller mold: 900r / min;

[0051] The feed speed of the male mold: take 0.08mm / r.

[0052] The metal fixing film sleeve manufactured with the above process parameters is post-processed to produce a FFS-30 metal fixing film with a length of 240 and a wall thickness of δ0.04. The surface roughness is high, smooth, without pits, creases, and Cracks, the number of printed and copied papers after installation test is 42,000.

Embodiment 2

[0054] Spinning stretching parameters used:

[0055] Thinning Δh and deformation ε: Δh=0.35; ε=0.87;

[0056] Bite angle γ: take 35°;

[0057] The diameter and quantity of the steel ball: the calculated diameter of the steel ball is φ3.8; the diameter of the steel ball is φ4;

[0058] The rotation speed of the roller mold: 900r / min;

[0059] The feed speed of the male mold: take 0.09mm / r.

[0060] The metal fixing film sleeve manufactured with the above process parameters is post-processed to produce FFS-24 metal fixing film with a length of 230 and a wall thickness of δ0.04. The surface roughness is high, smooth, without pits, creases, and Cracks, after the installation test, the number of printed and copied papers is 45,000.

Embodiment 3

[0062] Spinning stretching parameters used:

[0063] Thinning Δh and deformation ε: Δh=0.30; ε=0.80;

[0064] Bite angle γ: take 35°;

[0065] The diameter and quantity of the steel ball: the calculated diameter of the steel ball is φ3.3; the diameter of the steel ball is taken as φ3;

[0066] The rotation speed of the roller mold: 900r / min;

[0067] The feed speed of the male mold: take 0.09mm / r.

[0068] The metal fixing film sleeve manufactured with the above process parameters is post-processed to produce a FFS-24L metal fixing film with a length of 238.5 and a wall thickness of δ0.04. Cracks, after the installation test, the number of printed and copied papers is 45,000.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com