Novel connection device for telescopic and settlement seam of cable bridge frame

A technology of cable tray and connecting device, applied in electrical components and other directions, can solve problems such as inconvenient installation, and achieve the effect of protecting integrity and protecting electrical safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

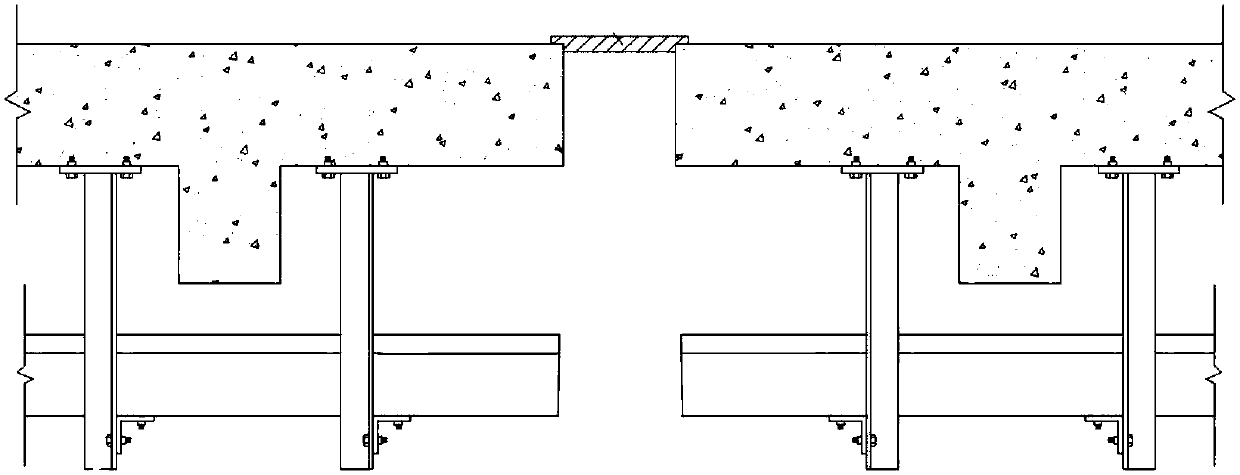

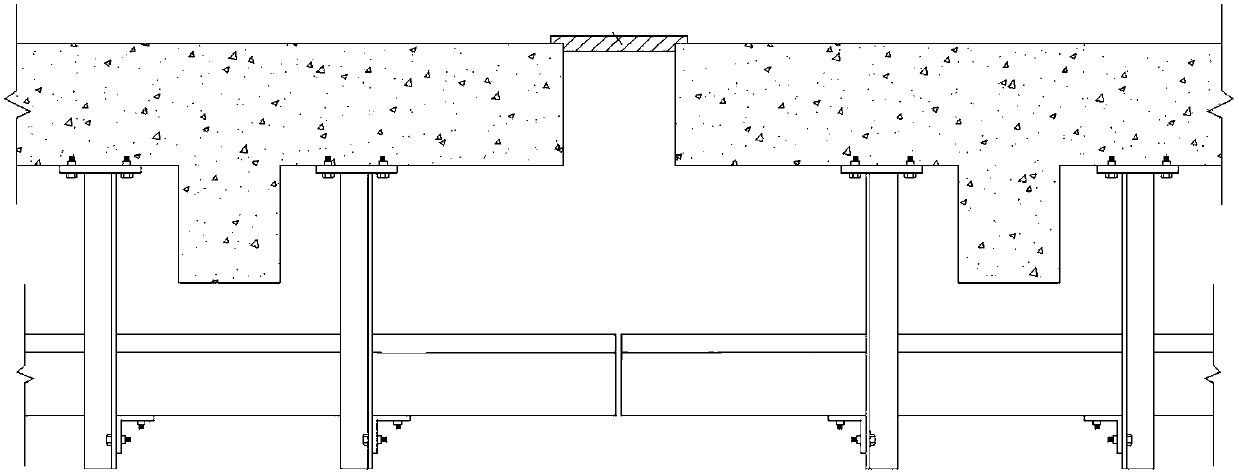

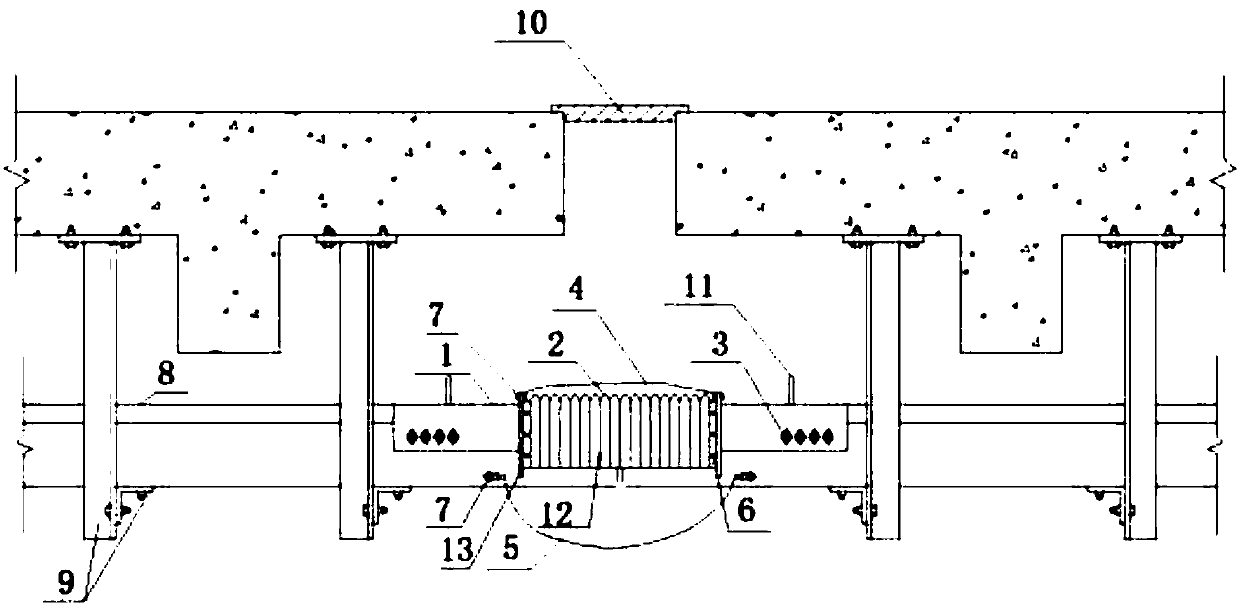

[0020] This application is mainly for figure 2 In this existing commonly used cable bridge installation implementation structure, a new type of cable bridge expansion and settlement joint connection device is implemented, such as Figure 3-4 As shown, it includes two sets of connecting mechanisms. The connecting mechanism includes a joint 1 and a U-shaped steel frame 13 welded and fixed to each other. The joint adopts a U-shaped cover plate size that matches the bridge frame, which is easy to install. A pair of steel handles is welded on the joint 1. 11. It is convenient for construction personnel to carry, and four bolt holes 3 are drilled on both sides of the joint 1 for fixing with bridge bolts. The U-shaped steel frame 13 is formed by welding three trapezoidal steel plates, and the thickness is between 5-10 mm. For different bridge specifications, commonly used bridge specifications are 200×100, 100×50, and the joint size can be adjusted accordingly. The nylon cloth at t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com