Film supply mechanism of bale wrapping machine

A film wrapping machine and straw bale technology, applied in the field of film supply mechanism, can solve the problems of accumulation in the film supply mechanism, loose film rolls, and different rotation speeds of guide shafts.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

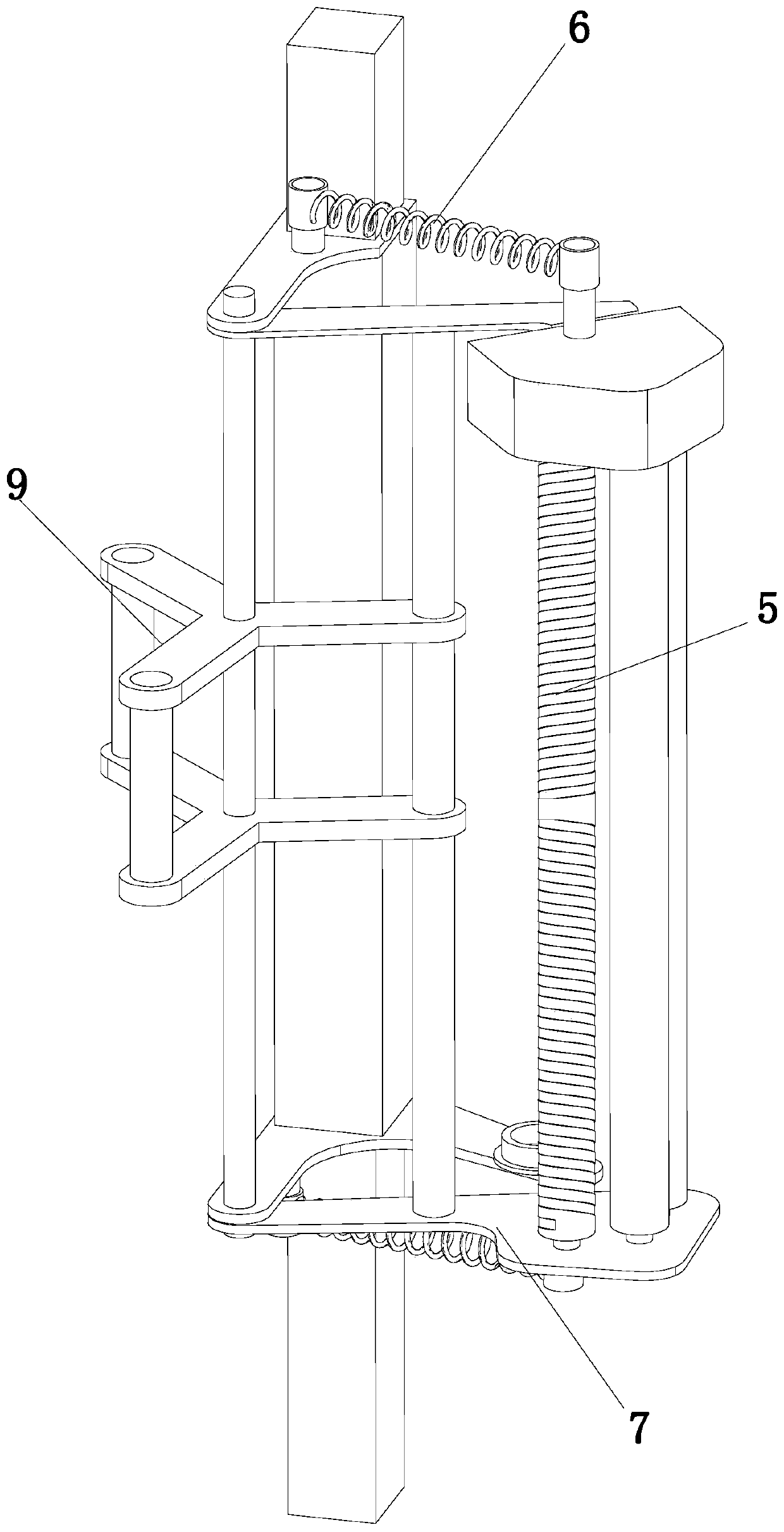

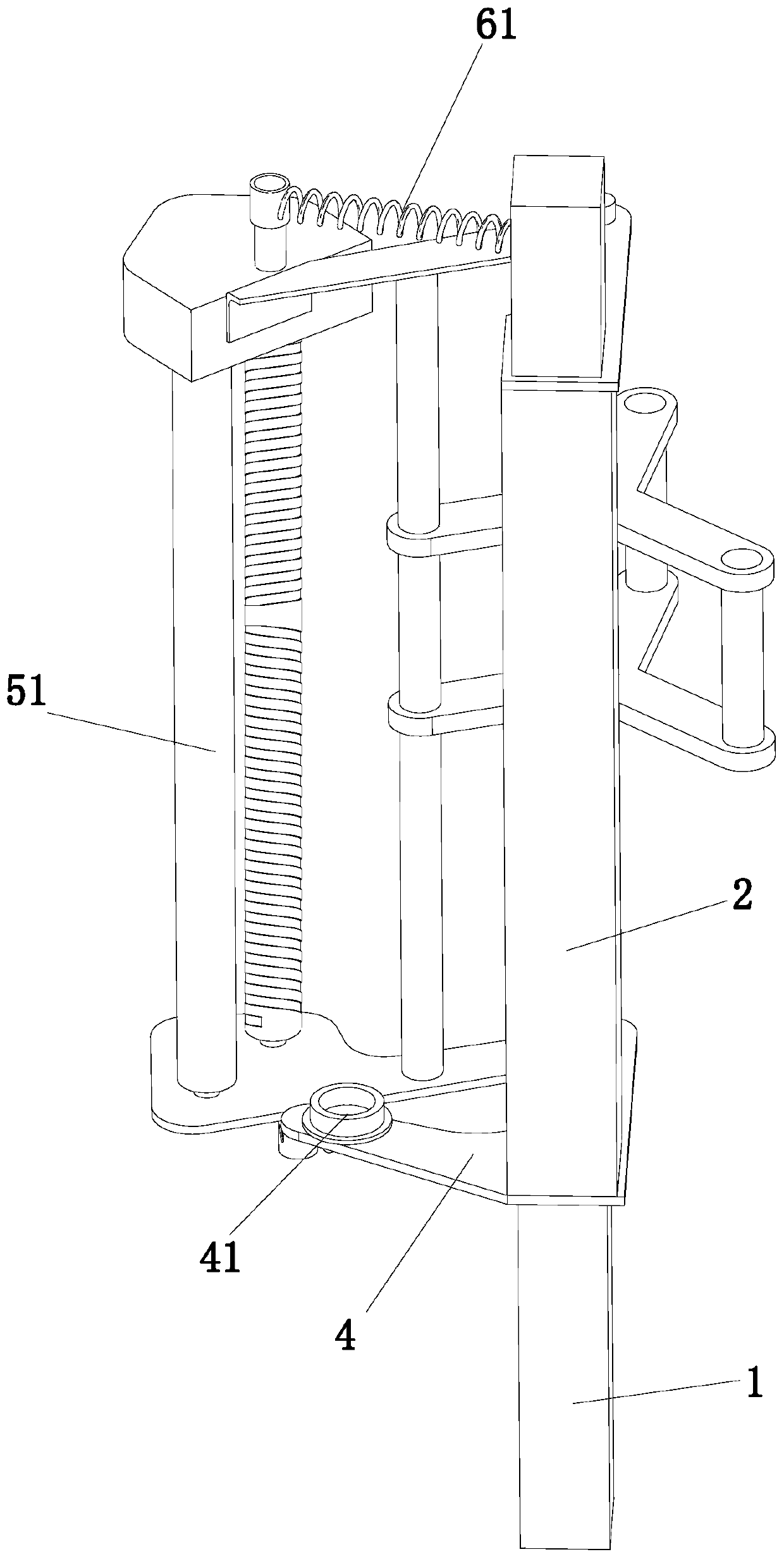

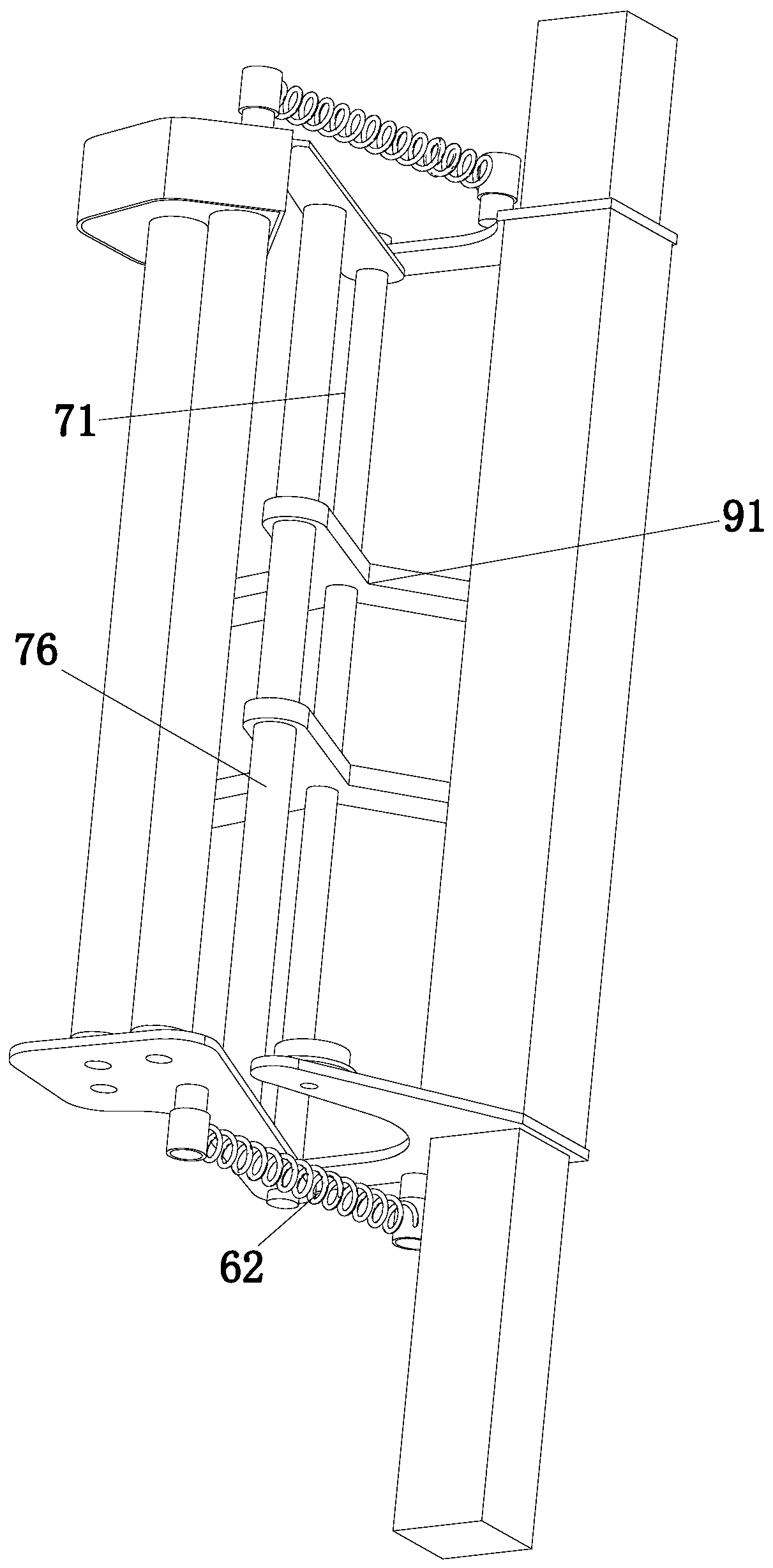

[0028] The present invention provides a film feeding mechanism of a bale wrapping machine through improvement, such as Figure 1-Figure 8 As shown, it includes a support rod 1 vertically installed on the bale wrapping machine, a guide sleeve 2 sleeved on the support rod 1 and a clamping device for clamping the roll film roller. The clamping device includes a useful The support platform 4 that supports the rotation of the roll film roller, the guide mechanism 5 that can always be attached to the surface of the roll film roller, and the pulling mechanism 6 for changing the distance from the guide mechanism 5 to the support platform 4, the support platform 4. It is horizontally and fixedly installed on the bottom of the guide sleeve 2. The guide mechanism 5 is rotatably matched with the guide sleeve 2 through the hinge frame 7. The pulling mechanism 6 is arranged on the hinge frame 7. The guide mechanism 5 includes several vertical The guide rollers 81 that are set and are rotata...

Embodiment 2

[0037] The present invention provides a film supply mechanism of a bale wrapping machine through improvement, such as Figure 1-Figure 8 As shown, it includes a support rod 1 vertically installed on the bale wrapping machine, a guide sleeve 2 sleeved on the support rod 1 and a clamping device for clamping the roll film roller. The clamping device includes a useful The support platform 4 that supports the rotation of the roll film roller, the guide mechanism 5 that can always be attached to the surface of the roll film roller, and the pulling mechanism 6 for changing the distance from the guide mechanism 5 to the support platform 4, the support platform 4. It is horizontally and fixedly installed on the bottom of the guide sleeve 2. The guide mechanism 5 is rotatably matched with the guide sleeve 2 through the hinge frame 7. The pulling mechanism 6 is arranged on the hinge frame 7. The guide mechanism 5 includes several vertical The guide rollers 81 that are set and are rotatab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com