Continuous tapered upsetting die and upsetting method for bar material with superhigh height-diameter ratio

A high-diameter ratio, upsetting technology, applied in the direction of manufacturing tools, forging/pressing/hammering machinery, metal processing equipment, etc., can solve the problems of long production cycle, complex processing of convex and concave mold blanks, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0048] In this example, the forging material is titanium alloy, the diameter of the original bar is 250mm, and the blank volume of the target forging is 79841.1237cm 3 , the calculated height of the cylindrical blank is 1626.51mm, therefore, the height-to-diameter ratio of the initial bar is as high as 6.506. According to the forging design requirements of the target forging, the aspect ratio of the blank is 0.256. That is, the round bar with an initial height-to-diameter ratio of 6.506 is upset into a cake-like preform with a height-to-diameter ratio of 0.256, providing a preform with a reasonable size and shape for the subsequent forging of the target forging.

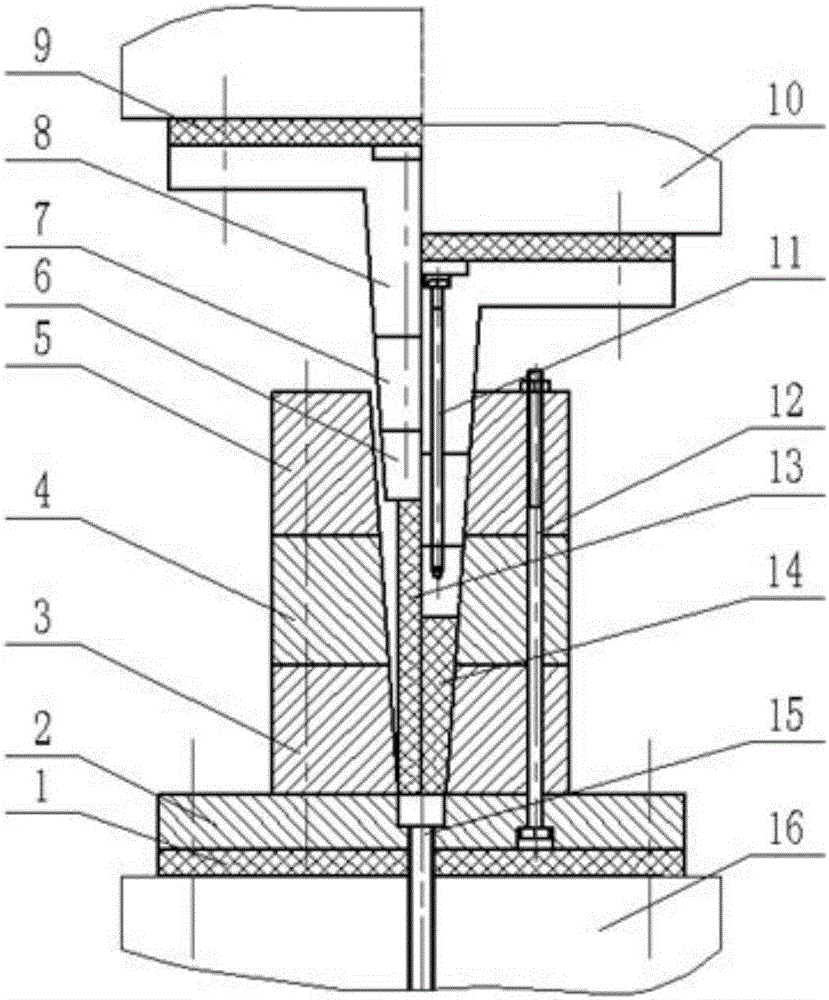

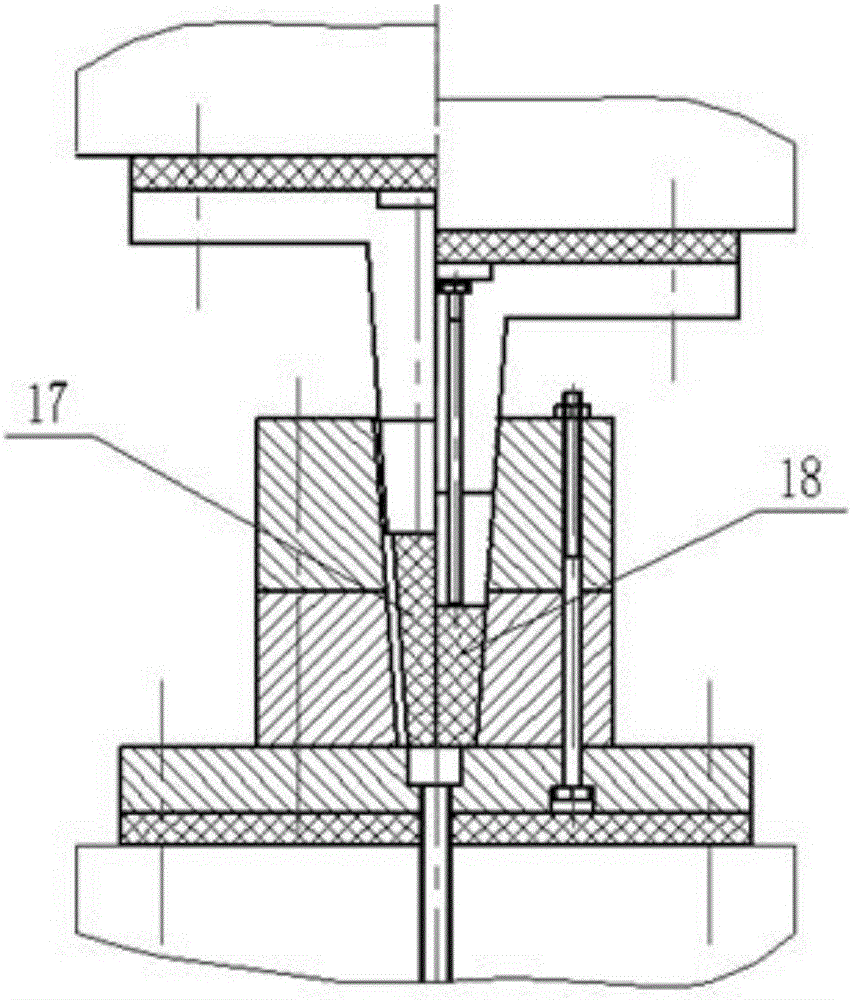

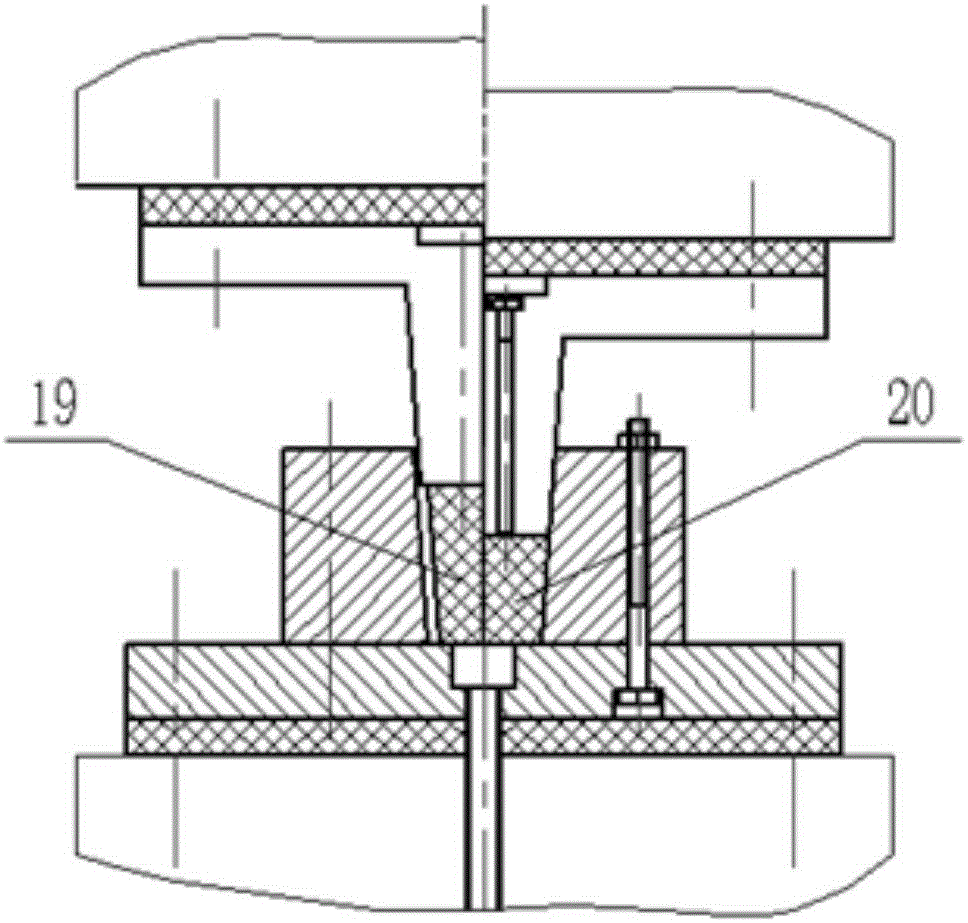

[0049] The schematic diagram of the mold structure of this embodiment is as figure 1 , figure 2 and image 3 As shown, the schematic diagrams of the mold before and after the first, secon...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com