Device for precisely processing deep groove and deep hole by variable-focus laser

A precision machining and variable focal length technology, applied in laser welding equipment, metal processing equipment, manufacturing tools, etc., can solve the problems of laser power density drop, insufficient sputtering force, and increased melting ratio, and achieve good heat dissipation and perforation The effect of large depth and long life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

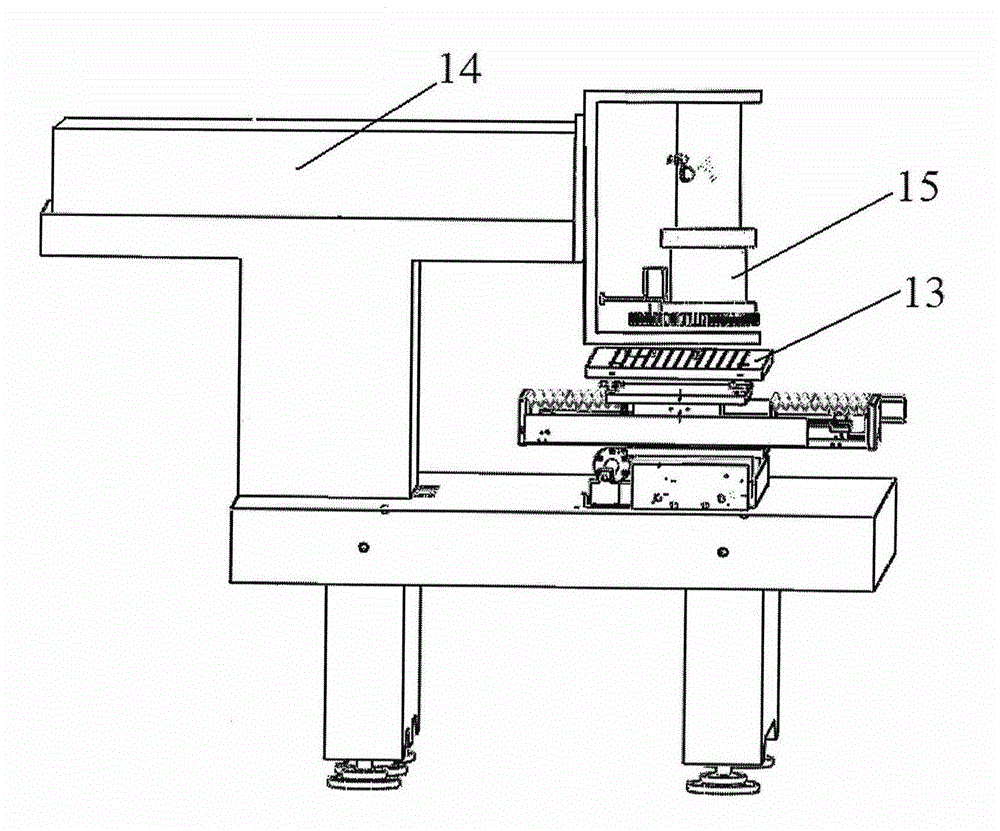

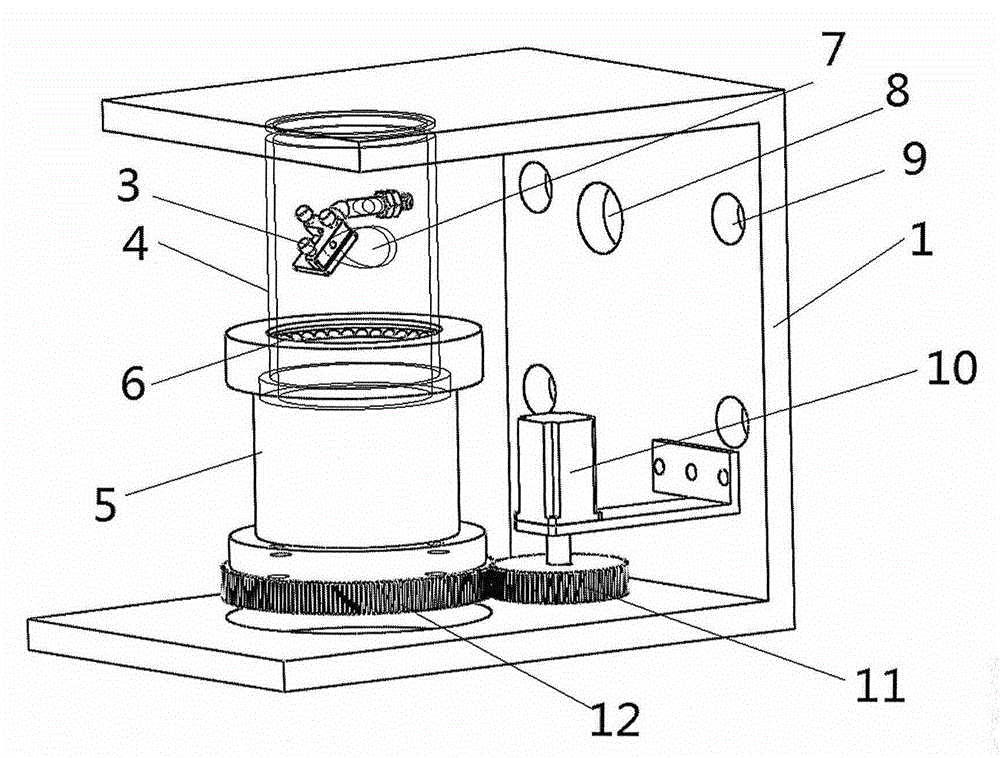

[0068] The method for performing zoom laser precision machining of deep grooves using the above-mentioned device specifically includes the following steps:

[0069] (1) The workpiece is clamped on the zoom laser precision machining deep groove and deep hole device, and 6 focusing lenses are evenly arranged and installed on the focusing lens seat, so that it meets the following conditions:

[0070] 1) The laser beam is incident on the central axis of a focusing lens on the focusing lens seat, vertically incident along the Z direction and focused on the surface of the workpiece;

[0071] 2) The workpiece can be driven by the worktable to do translational movement in the X-Y direction, that is, the focused spot of the laser beam moves relatively on the surface of the workpiece;

[0072] 3) XYZ forms a Cartesian coordinate system;

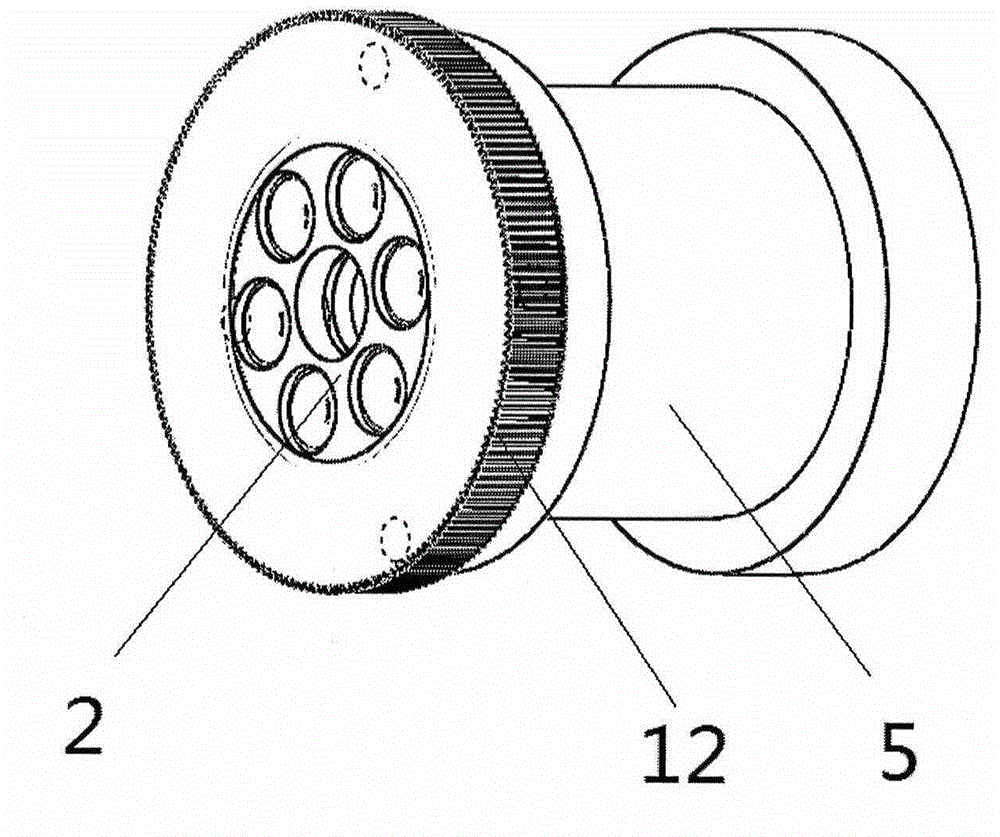

[0073] 4) The diameter of the focus lens seat is 180mm. The diameter of the six focus lenses installed on it is 25mm, and the focal lengths are 120.0...

Embodiment 2

[0079] The method for performing zoom laser precision machining of deep holes using the above-mentioned device specifically includes the following steps:

[0080] (1) Clamp the workpiece and 8 focusing lenses on the zoom laser precision machining deep groove and deep hole device, so that it meets the following conditions:

[0081] 1) The laser beam is incident on the central axis of a focusing lens on the focusing lens seat, vertically incident along the Z direction and focused on the surface of the workpiece;

[0082] 2) The workpiece can be driven by the worktable to do translational movement in the X-Y direction, that is, the focused spot of the laser beam moves relatively on the surface of the workpiece;

[0083] 3) XYZ forms a Cartesian coordinate system;

[0084] 4) The diameter of the focusing lens seat is 250mm, and the diameters of the 8 focusing lenses installed on it are all 30mm, and the focal lengths are 100.0mm, 120.2mm, 120.4mm, 120.6mm, 120.8mm, 121.0mm, 121.2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com