Laser induced variable polarity square wave tungsten argon arc welding method for small-hole-diameter thin-walled tube

A tungsten electrode argon arc welding and tungsten electrode argon arc technology, applied in welding equipment, welding accessories, arc welding equipment and other directions, can solve the problems of arc spot interference, poor welding precision, etc., to reduce tungsten electrode burnout, welding High speed and the effect of increasing welding speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

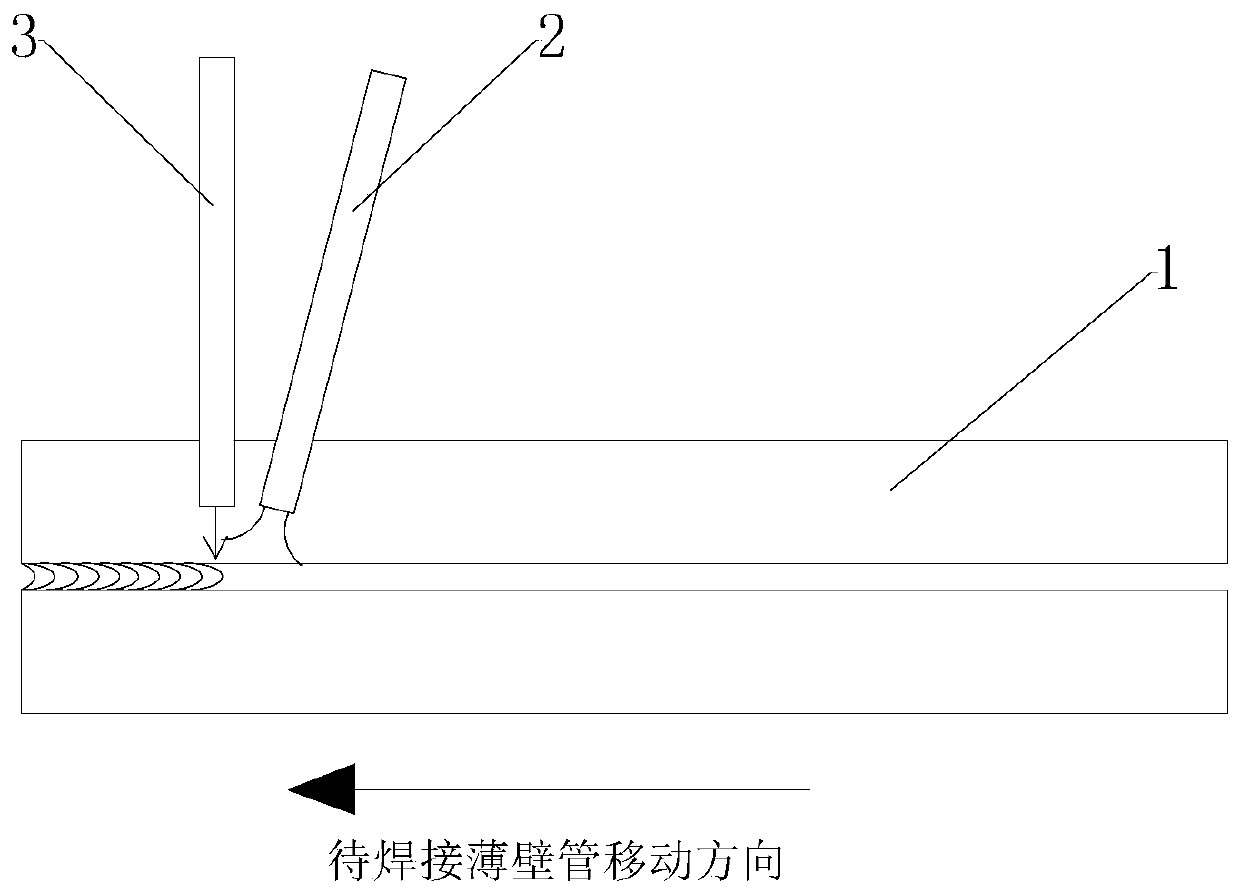

[0026] Now, the present invention will be further described in detail in conjunction with the accompanying drawings and specific embodiments. All technologies realized based on the following contents belong to the protection scope of the present invention.

[0027] The following embodiments will be described in detail by taking welding a 2 mm thick aluminum alloy pipe fitting as an example.

[0028] The type of laser used is DSS266-Q1, the pulse width is <1ns, the wavelength is 266nm, and the maximum repetition rate is 5KHZ.

[0029] The model of variable polarity square wave tungsten argon arc welding machine used is VPTIG-315, the rated voltage is 0-380V, the arc closing current is 5-315A, and the duty cycle is 60%.

[0030] The specific working process of laser-induced variable polarity square-wave tungsten argon arc welding of small-aperture thin-walled tubes in the present invention is as follows:

[0031] (1) Laser beam emitting gun 2 and variable polarity square wave t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Defocus amount | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com