Surface micro-morphology processing method of gear composite plastic forming die

A technology of plastic forming and processing methods, which is applied in the direction of manufacturing tools, forging/pressing/hammer devices, forging/pressing/hammering machinery, etc., to achieve the effects of improving metal flow, increasing die life, and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

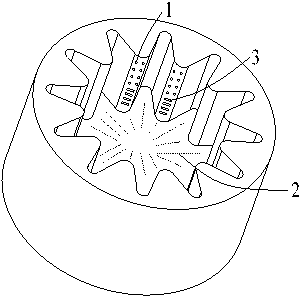

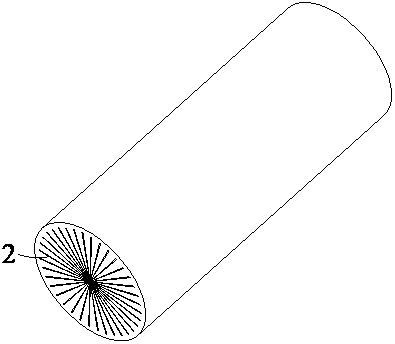

[0055] Example 1: Multi-station hot precision forging-cold extrusion plastic forming of spur gears

[0056] Laser processing equipment: SPI fiber laser.

[0057] The concrete implementation of the present invention its steps are:

[0058] The first step: provide SPI fiber laser. Determine the basic parameters of the laser: laser power 50W, pulse width 5000 .

[0059] The second step: Determine the maximum forming pressure area of the multi-station precision forging die and cold extrusion die, that is, the tooth top and tooth root of the precision forging die.

[0060] The third step is to drive the laser equipment, adjust the laser parameters such as laser power density, pulse width, and pulse frequency, and adopt the laser processing technology of "single pulse at the same point multiple times" in the lower die of the pier rough station of the multi-station hot die forging die Micro-pit 1 is processed at the place with the highest forming pressure (tooth shape), and th...

example 2

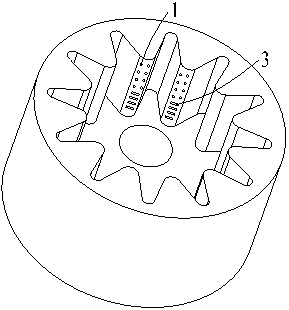

[0066] Example 2: Multi-station Hot Precision Forging-Cold Extrusion Plastic Forming of Spur Bevel Gears

[0067] The first step is to provide SPI fiber laser. Determine the basic parameters of the laser: laser power 50W, pulse width 5000 .

[0068] The second step is to determine the area with the highest forming pressure during the forming process of the multi-station precision forging die, that is, the tooth top and tooth root of the precision forging die.

[0069] The third step is to drive the laser equipment and adjust laser parameters such as laser power density, pulse width, and pulse frequency. Using the "single pulse at the same point with multiple intervals" laser processing technology, the shape of the micro-pit 1 with a diameter of 90 is processed at the point where the forming pressure of the lower die is the highest (tooth shape) at the pier rough station of the multi-station hot die forging die. , depth 40 , Density 10%. In addition, nanometer molybdenu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com