Hydraulic machine hydraulic system capable of realizing local loading rapidly and stably

A local loading and hydraulic system technology, applied in the field of hydraulic press hydraulic system, can solve the problems of limited application, long forming cycle, low efficiency, etc., and achieve the effects of rapid response, reduced energy consumption, and reduced pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

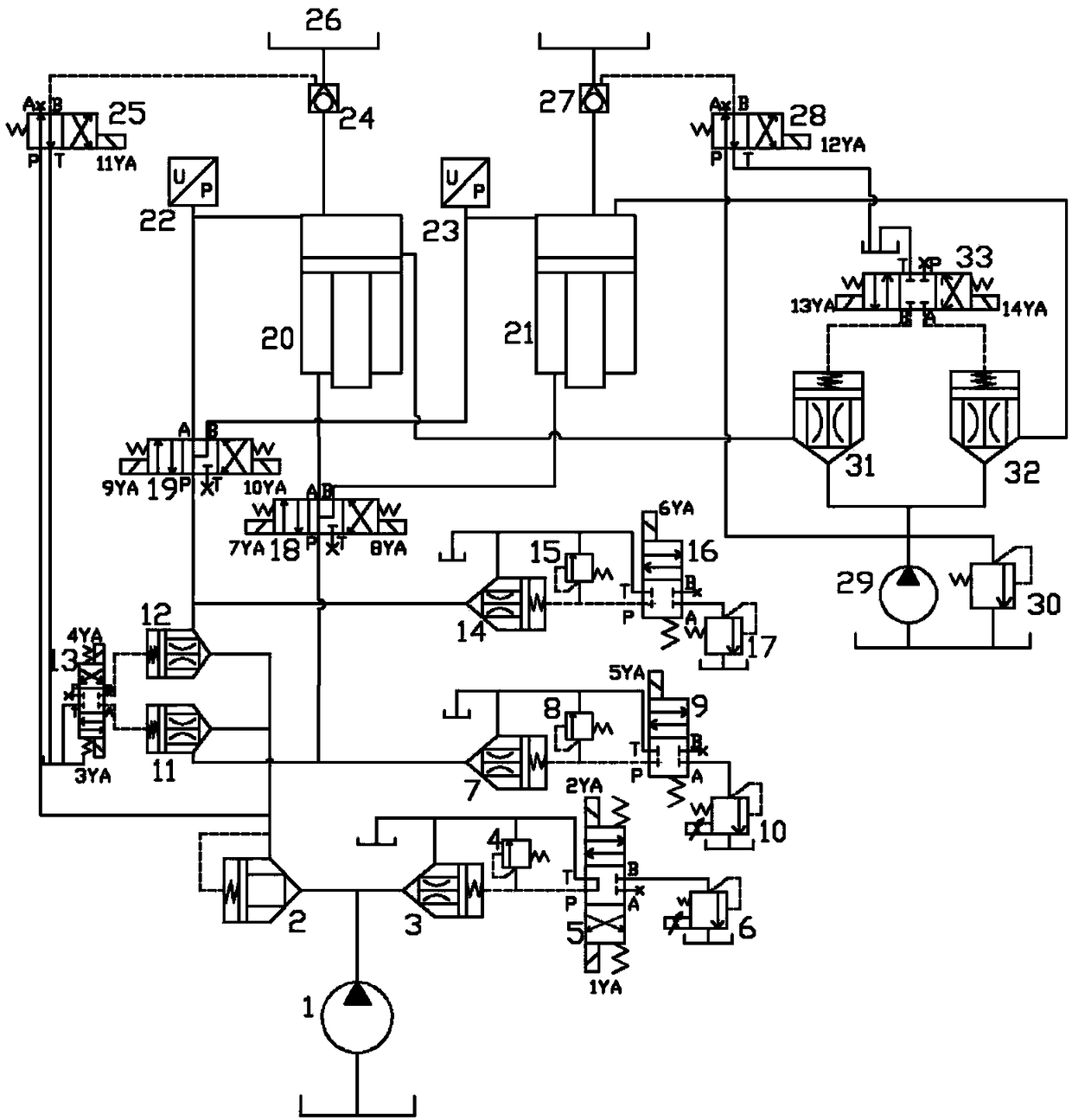

[0021] refer to figure 1 , a hydraulic system of a hydraulic press capable of quickly and stably realizing local loading, including a power output system, a pressure control system and a loading system, a cartridge valve 2 of the power output system, an oil outlet and a second pressure control cartridge valve 11 of the pressure control system The oil inlet is connected to the oil inlet of the first pressure control cartridge valve 12; the A port and B port of the fourth electromagnetic reversing valve 18 of the pressure control system are respectively connected to the first hydraulic cylinder 20 and the second hydraulic cylinder 21 of the loading system The lower chamber, the A port and the B port of the fifth electromagnetic reversing valve 19 of the pressure control system are respectively connected to the upper chamber of the first hydraulic cylind...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com