Device and method for compounding and forming central flange pipe joint from pipe blank in single-step and multi-directional way

A composite forming and tube blank technology, applied in mechanical equipment, engine components, metal processing equipment, etc., can solve the problems of different plastic processing technology, low material utilization rate, low production efficiency, etc., to save processing time and material utilization. The effect of high rate and few steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

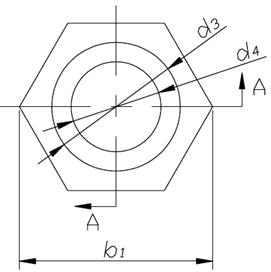

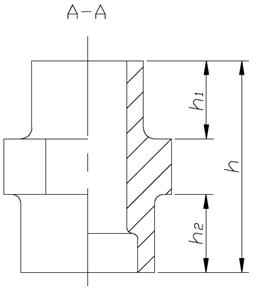

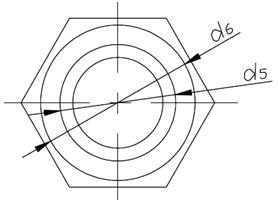

[0033] Example: A Typical Mid-Flanged Fitting, Small End OD d 3 =20mm, height h 1 =14mm, outer diameter of big end d 6 =24mm, height h 2 =14mm, through hole diameter d 4 =12mm, big end step hole diameter d 5 =17.8mm, the hexagonal flange in the middle is simplified into a cylindrical flange with a diameter of 30mm, and the overall height of the pipe joint in the middle flange h =38mm; the material is 15#; the outer diameter of the tube blank is used d 2 =28mm, inner diameter d 1 =13mm, tube blank length L =27.5; Die mandrel 5 is placed in the outer ring 4 of the die, the tube blank is placed on the mandrel 5 of the die, and the punch 3 is installed in the regular hexagonal cavity 6 at the upper end of the outer ring of the die. The billet is extruded from top to bottom on a 2000KN hydraulic press, the metal filling is in good condition, and the metal flow is consistent with the design.

[0034] The one-step multi-directional compound forming method of the middl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com