Preparation of low-temperature primary sintering high-density superfine crystal particle pure tungsten material

An ultra-fine grain and secondary sintering technology, which is applied in the field of preparation of high-density ultra-fine grain pure tungsten material by low-temperature primary sintering, can solve the problems of difficulty in forming nano-powders, and achieves lower sintering temperature, high production efficiency and high density. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

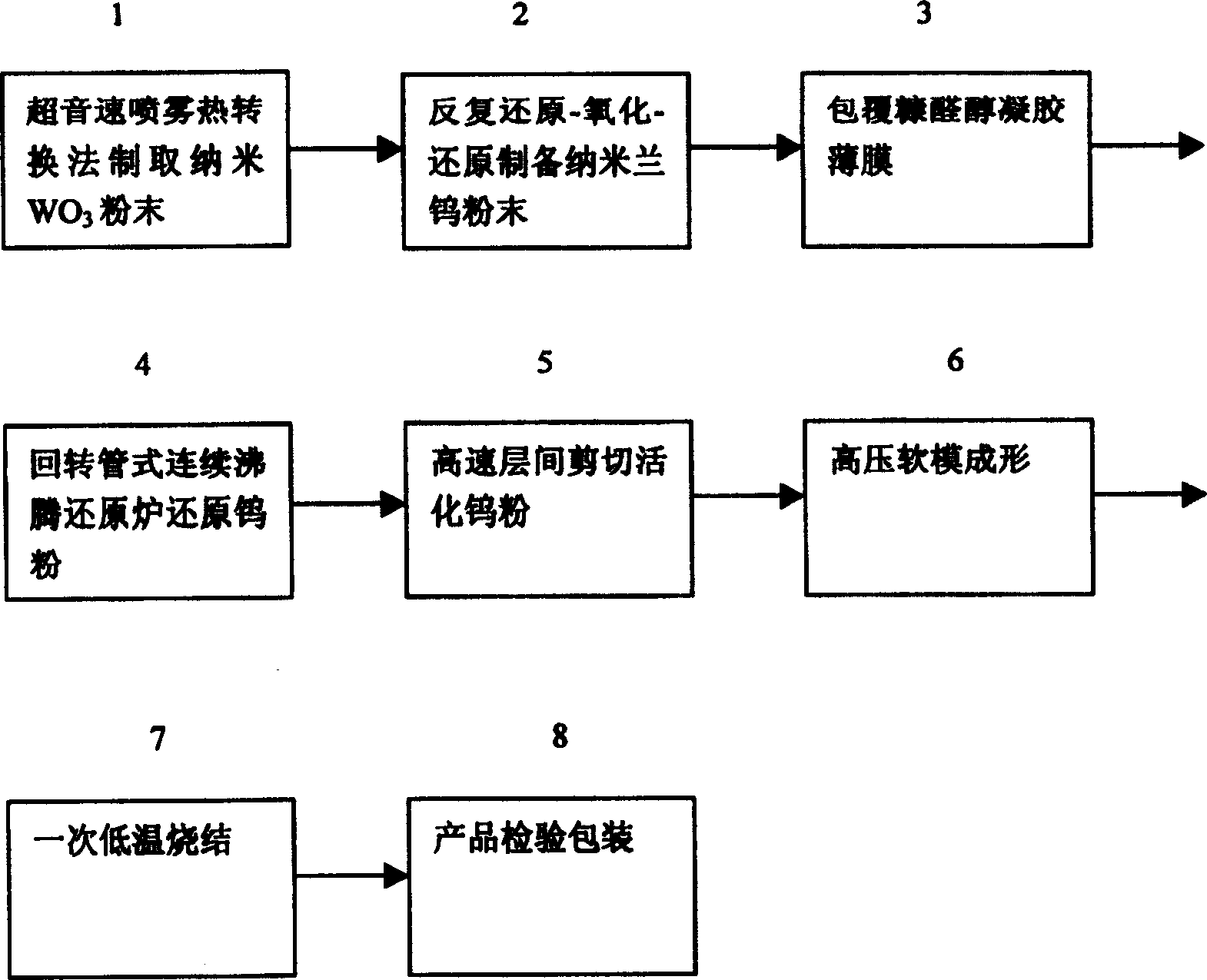

Method used

Image

Examples

Embodiment 1

[0033] Embodiment 1: When preparing 10Kg of high-density ultra-fine grain pure tungsten material, it should be completed according to the following steps.

[0034] 1. Preparation of nano-WO with average particle size ≤ 40nm 3 powder

[0035] Weigh 34.08 liters of high-concentration ammonium tungstate solution, its WO 3 The content is 370g / liter, using the supersonic spray heat conversion method, at the air injection pressure 6.5MPa, the air injection speed 830m / s, the nozzle injection angle α=50°, the focal length F=11.5mm, hot air temperature 400 ℃, countercurrently send hot air, liquid The flow rate is 400ml / min, and the high-concentration ammonium tungstate solution is made into 12.6kg of nano-scale WO 3 Powder, average particle size ≤40nm.

[0036] 2. Repeated reduction-oxygen-reduction to prepare blue tungsten powder with finer particle size.

[0037] Nano-WO with an average particle size ≤ 40nm 3 powder in a tubular reduction furnace at 500°C for 45 minutes, and the...

Embodiment 2

[0048] Example 2, when preparing 1Kg of high-density ultra-fine grain pure tungsten material, it should be completed according to the following steps.

[0049] 1. Preparation of nanoscale WO 3 powder

[0050] Weigh 3.41 liters of high-concentration ammonium tungstate solution, its WO 3 The content is 350g / liter, using the supersonic spray heat conversion method, at the air jet pressure 5MPa, jet speed 664m / s, nozzle jet angle α=50° focal length F=11.5mm, hot air temperature 350°C, countercurrent hot air flow, liquid flow The delivery speed is 400ml / min, and the high-concentration ammonium tungstate solution is made into 1.26kg nano-scale WO 3 Powder, average particle size ≤40nm.

[0051] 2. Repeated reduction-oxygen-reduction to prepare blue tungsten powder with finer particle size.

[0052] ≤40nm nano WO 3 powder in a tube-type reduction furnace at 450°C for 60 minutes, and nano-WO 3 All powders are restored to WO 2.9 Blue tungsten powder, then 550 ° air flow in the tu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com