Freezing pulverizing machine

A freezing pulverizer, No. 1 technology, which is applied in grain processing and other directions, can solve the problem of difficult to meet the requirements of one-time pulverization, and achieve the effect of fine particle size and guaranteed performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings.

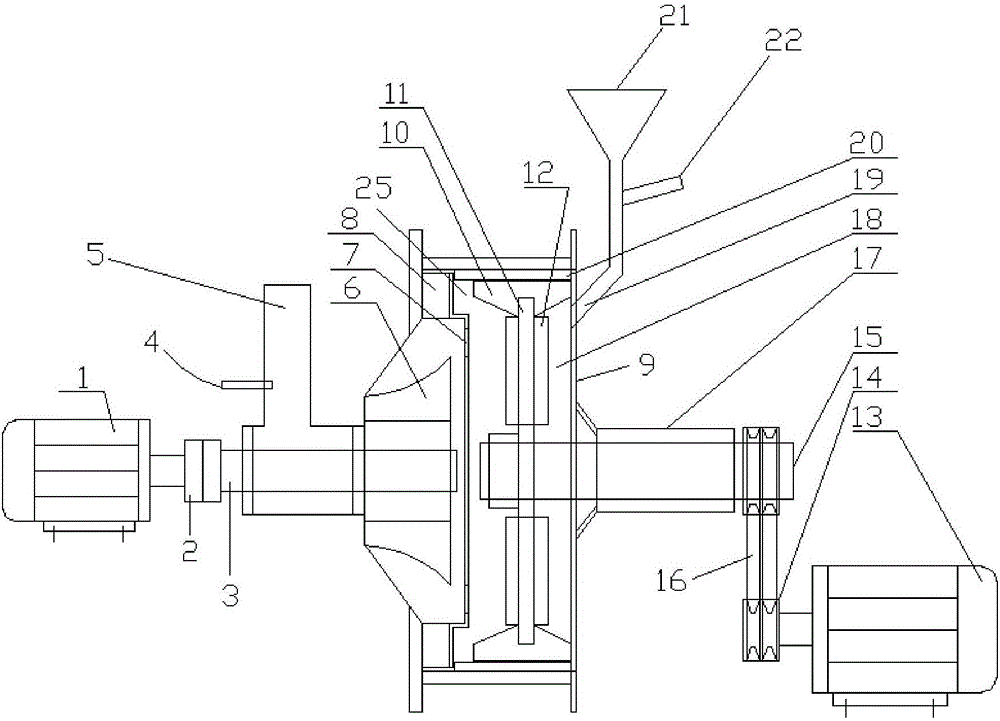

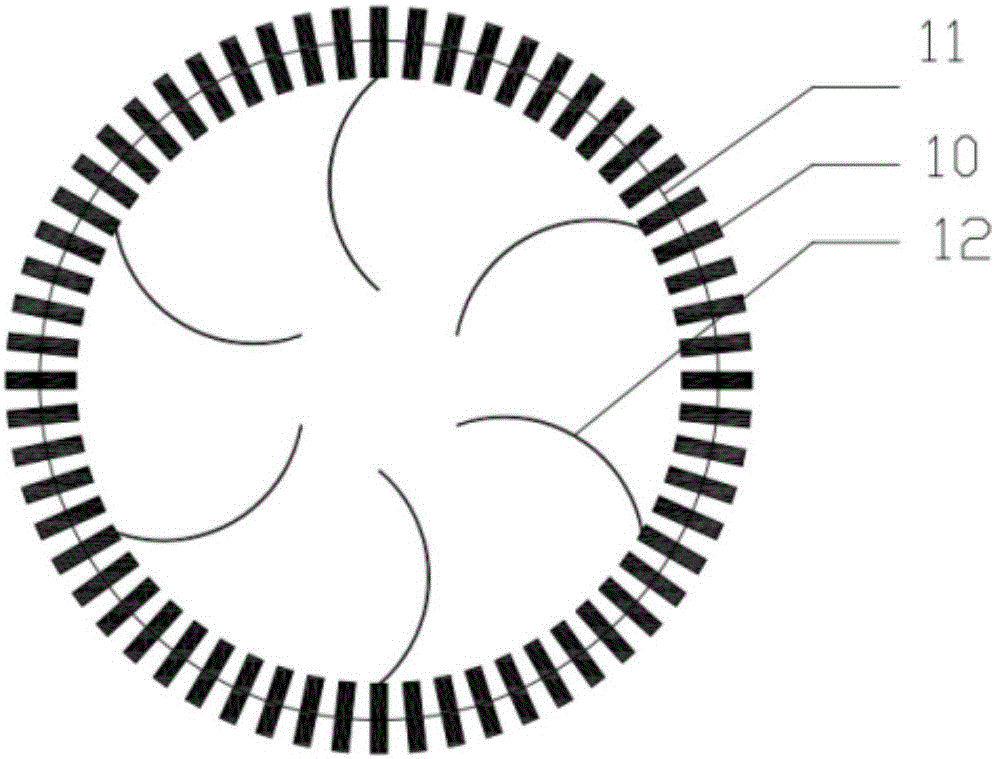

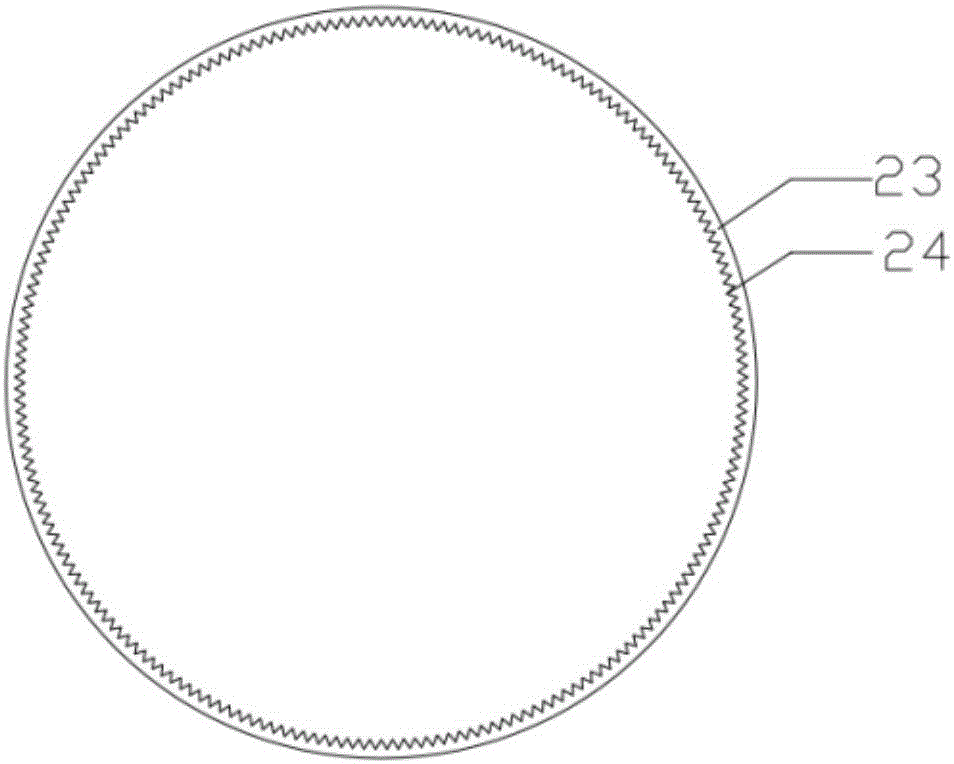

[0016] Such as figure 1 , figure 2 and image 3 As shown, it includes a grinder 9, a feed inlet 21, a liquid nitrogen inlet 22, a classification wheel 6, a discharge pipe 5, a No. 1 motor 13 and a No. 2 motor 1, and the feed inlet 21 and the liquid nitrogen inlet 22 The feed pipe 19 communicates with the grinder 9, and the material is initially mixed and cooled with liquid nitrogen in the feed pipe 19, then sent into the grinding chamber 18, further mixed with liquid nitrogen, and frozen; the other part of the grinder 9 One end is connected to one end of the classifying wheel 6, and the other end of the classifying wheel 6 is connected to the discharge pipe 5, and the No. 1 motor 13 drives the grinder 9, and the grinder 9 includes a grinding chamber 18. The cutterhead base 11, the movable cutter set 10, the movable c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com