Horizontal type roller mill

A drum roll and mill technology, applied in grain processing, etc., can solve problems such as complex structures, and achieve the effects of improving production efficiency, high reliability, and reducing beating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

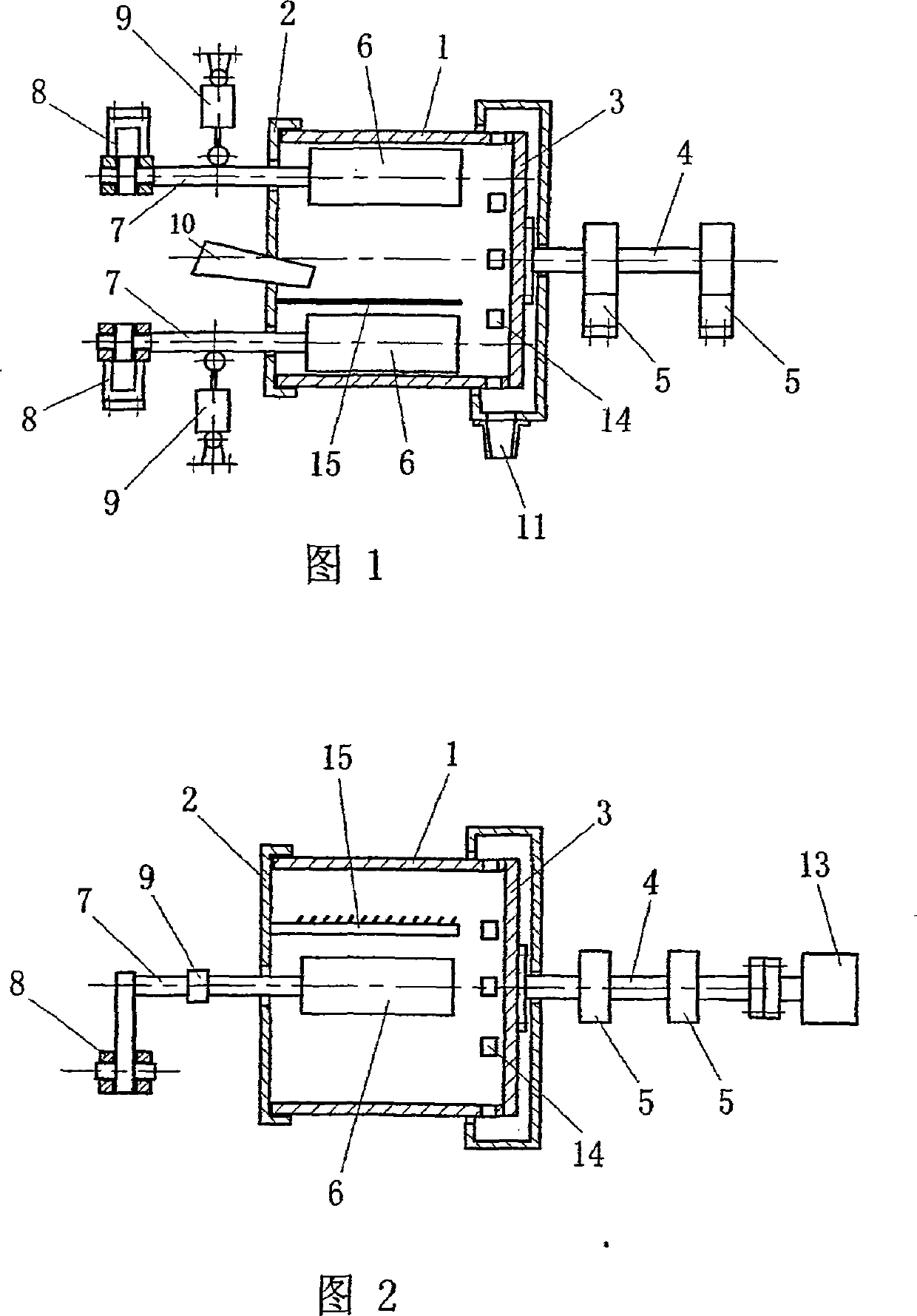

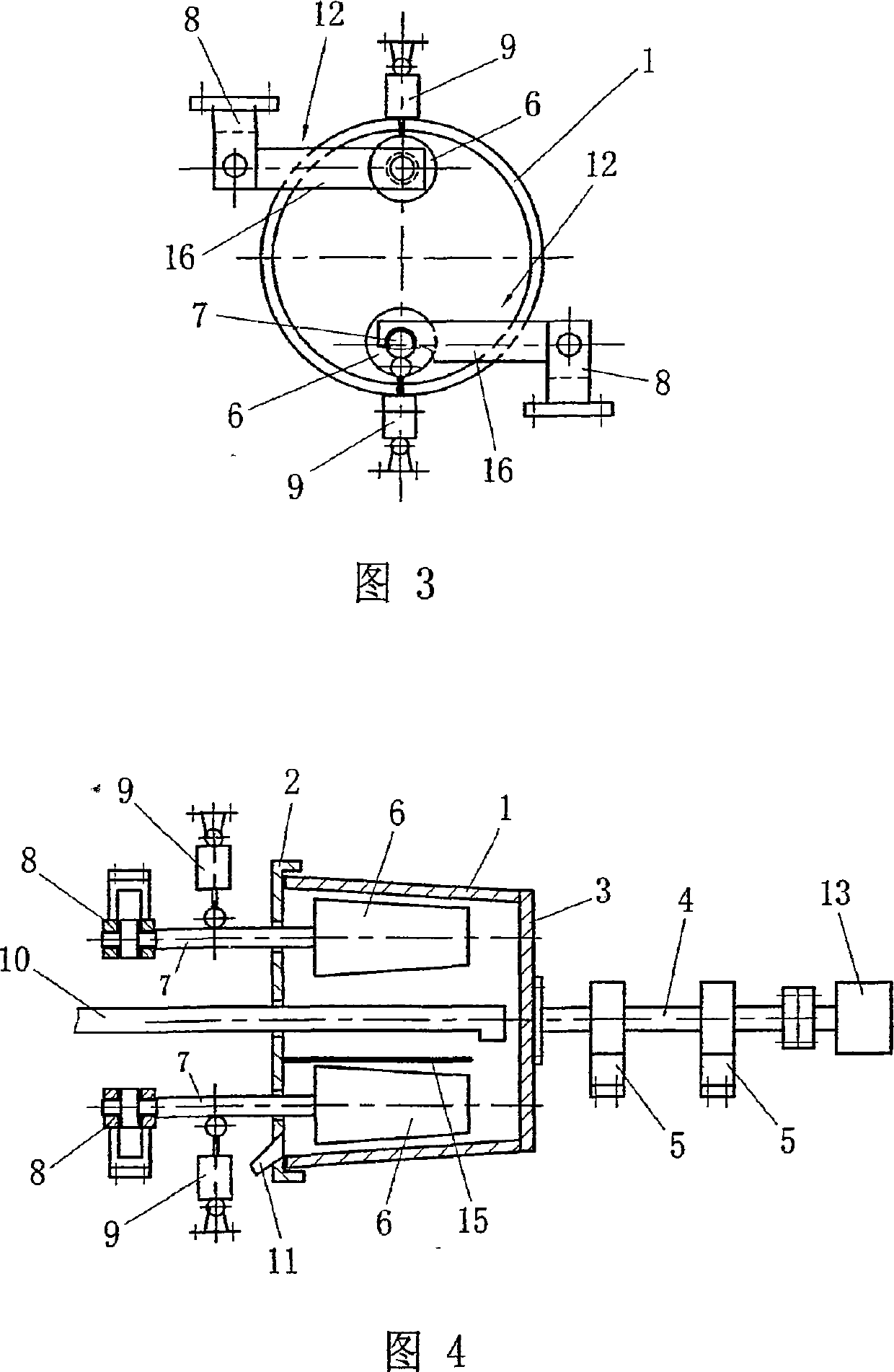

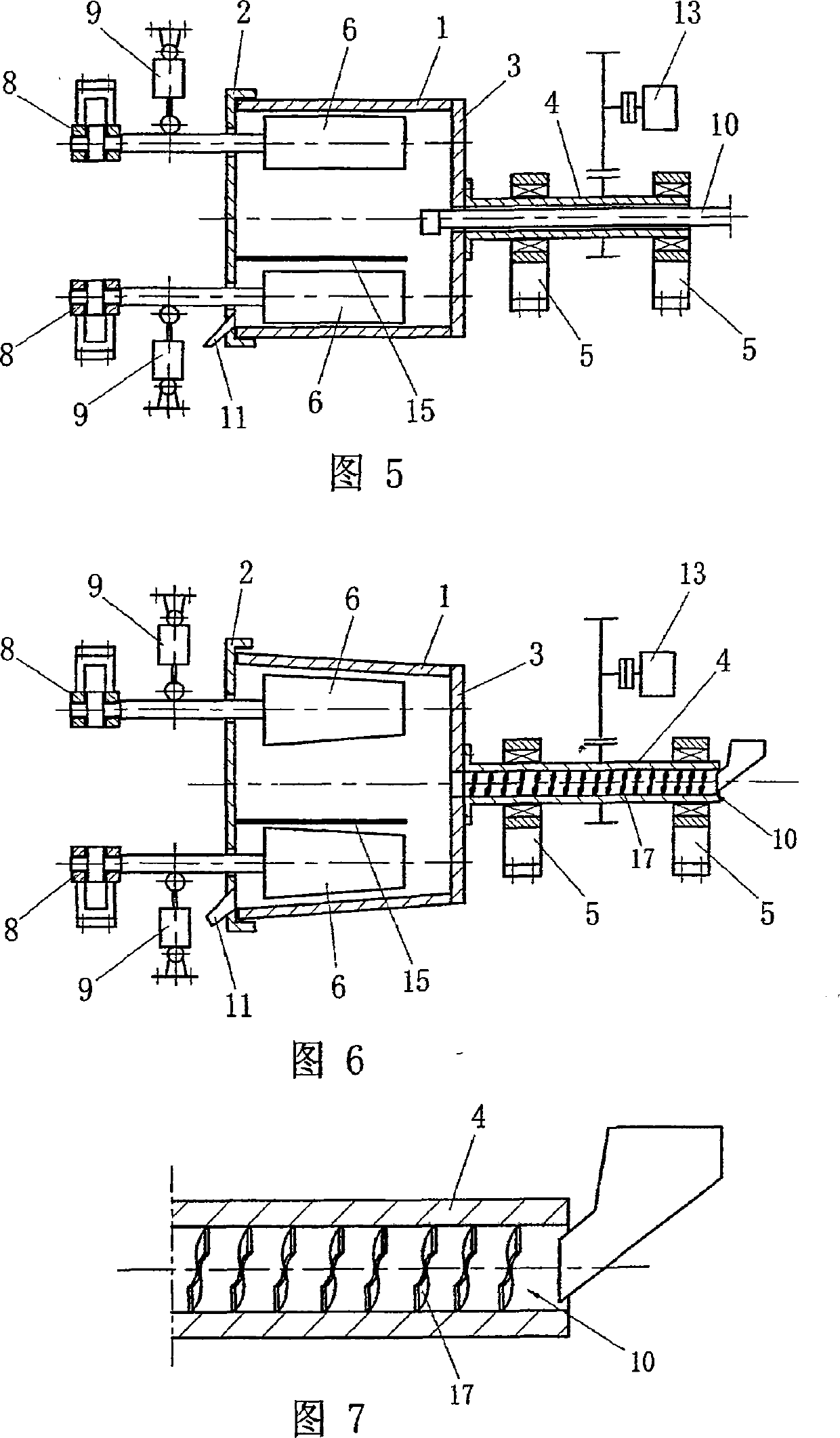

[0020] see figure 1 , figure 2 .

[0021] There is a grinding cylinder 1 and a grinding cylinder driving mechanism, figure 2 The figure shows the grinding cylinder driving mechanism 13 schematically. The grinding cylinder 1 is cylindrical, and the roller surface of the grinding roller 6 is a corresponding cylindrical roller surface. The prefabricated part is fixed; the other end of the grinding cylinder is an end wall 3 fixed integrally with the grinding cylinder, the end wall 3 is connected to the drive shaft 4, and the drive shaft 4 is provided with a support seat 5 that constrains the grinding cylinder. Axially and radially achieve stable restraint. The support seat 5 can be a strip-shaped piece along the axial direction of the drive shaft. Parts, that is, the grinding cylinder 1 that is stably restrained in a cantilever state; there are at least two grinding rollers 6 distributed along the circumferential direction of the grinding cylinder in the grinding cylinder, pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com