Patents

Literature

42results about How to "Improve plastic forming ability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Precision die forging and shaping technical method for automobile steering knuckle rough type parts

InactiveCN102672096ALow forming speedNo crack phenomenonRailway componentsMetal-working apparatusEngineeringMaterial distribution

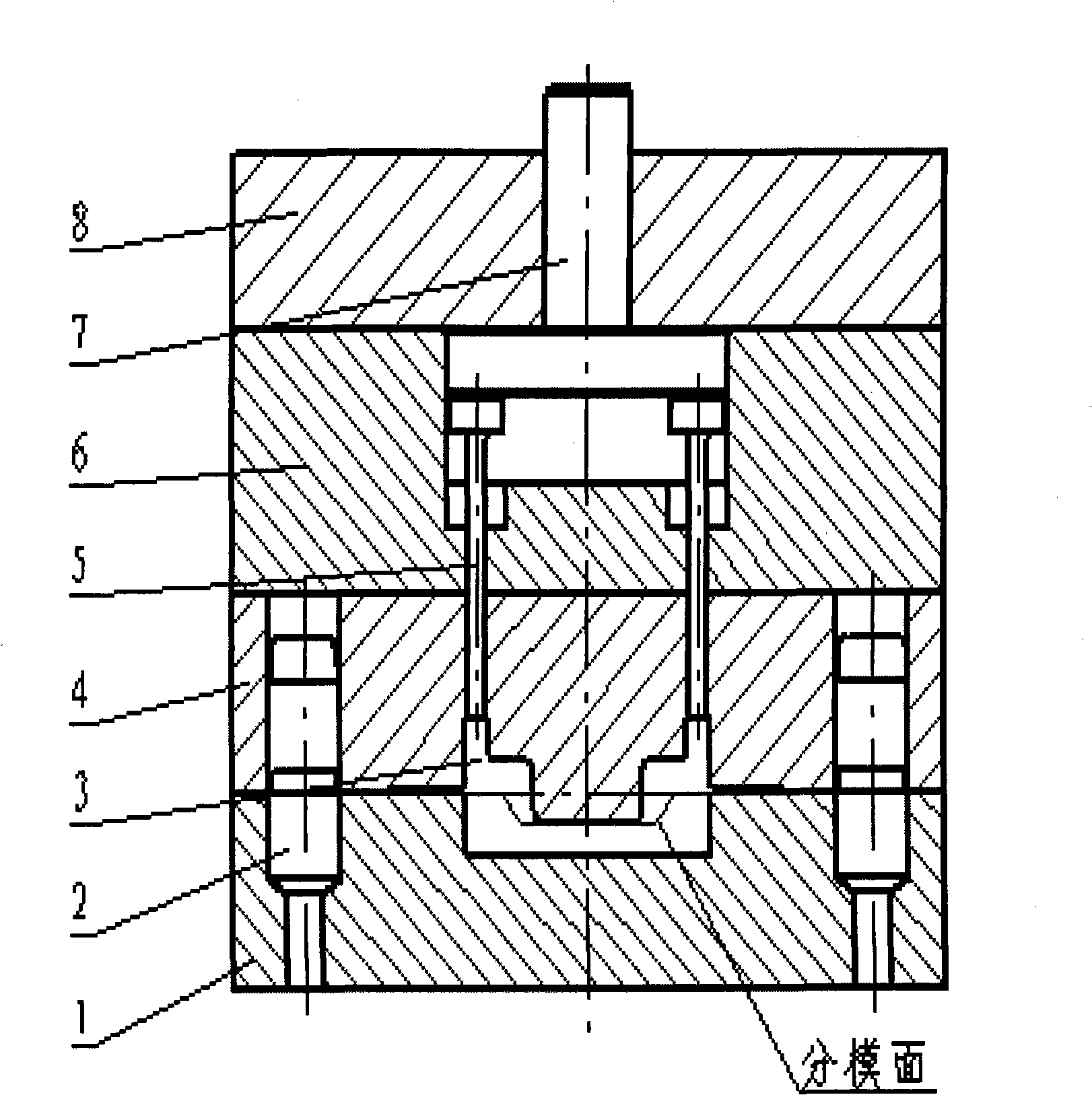

The invention provides a precision die forging and shaping technical method for automobile steering knuckle rough type parts. The precision die forging and shaping technical method mainly comprises the process steps of blanking, heating, extruding and drawing out a rod part, pre-forging, upsetting, performing material distribution and performing multi-way precision die forging and shaping and is specifically as follows: blanking through a cutting device, and heating to the temperature of 1080 DEG C-1180 DEG C in a medium-frequency induction furnace; placing a round bar which is well heated into a female die of an extruding and drawing-out die to form a stock comprising a cylindrical surface and a steering knuckle rough rod part; placing the stock after upsetting and material distribution into a multi-way die forging die, firstly enabling an upper male die and an upper die seat in the vertical direction to move downwards, and closing the upper male die and a lower female die for forging; and then using male dies on the symmetrical left side and right side in the horizontal direction to perform extrusion precision forging and shaping. According to the method provided by the invention, as the die forging is performed on a multi-way die forging hydraulic machine, the shaping speed is much lower than that of die forging on a hammer, thus the occurrence of the phenomenon of forming cracks on the surface due to strong speed sensitivity caused by too-high speed can be avoided; and the contact friction resistance between a forged piece and the surface of a die cavity during the processes of die forging, shaping and ejection of the forced piece can be greatly reduced, the surface quality of the forged piece is further improved, and the utilization rate of the material of the forged piece is improved.

Owner:CHONGQING UNIV OF TECH

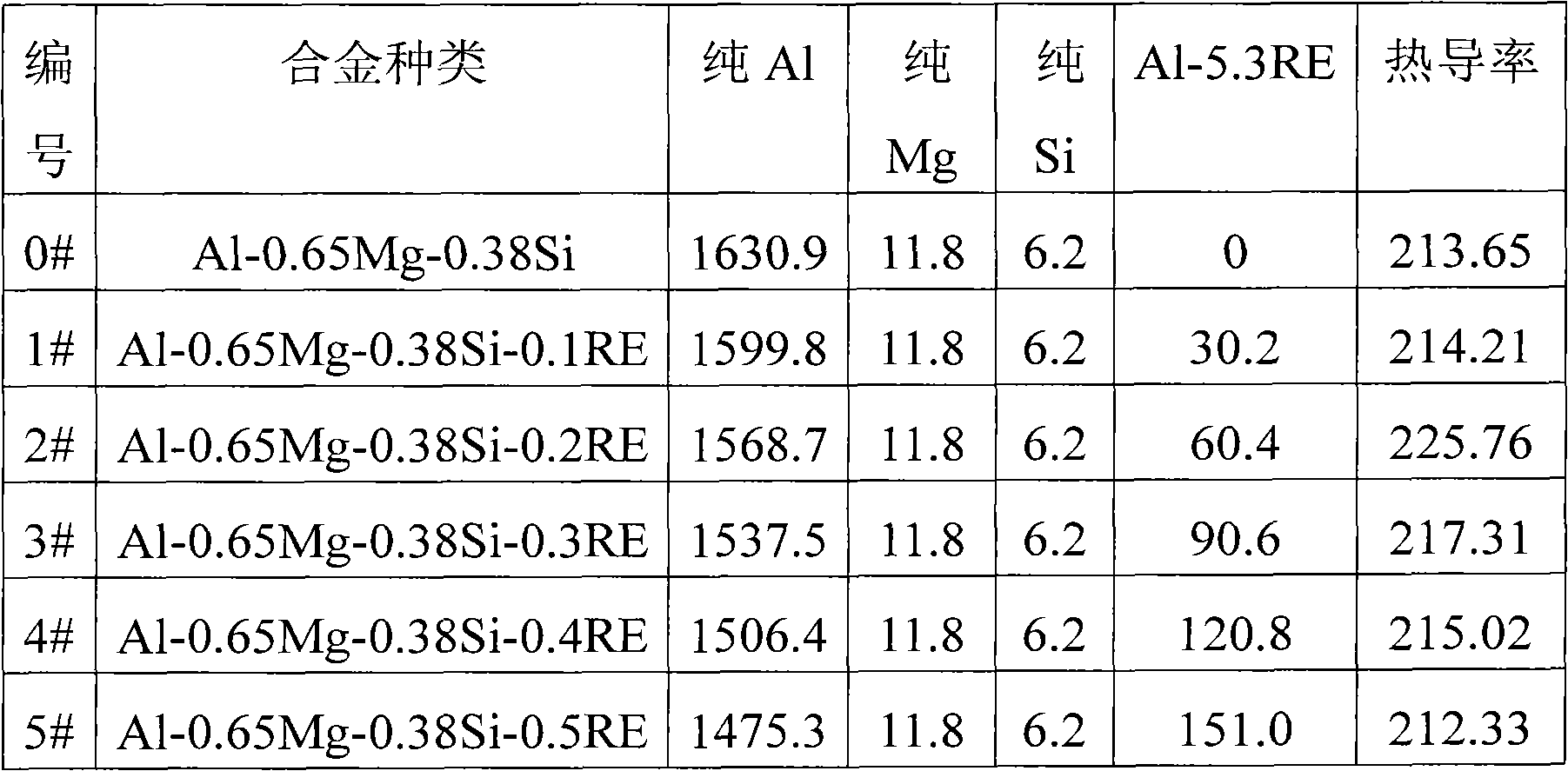

Rare earth aluminum alloy with high thermal conductivity

The invention provides a rare earth aluminum alloy with high thermal conductivity. Mixed rare earth element RE composed of lanthanum and yttrium is added into 6063 aluminum alloy to form the rare earth aluminum alloy, wherein in the 6063 aluminum alloy, Mg accounts for 0.45 to 0.8 weight percent of the total weight of the rare earth aluminum alloy, Si accounts for 0.25 to 0.6 weight percent of the total weight of the rare earth aluminum alloy, Fe accounts for less than 0.35 weight percent of the rare earth aluminum alloy, Cu accounts for less than 0.1 weight percent of the rare earth aluminum alloy, Zn accounts for less than 0.1 weight percent of the rare earth aluminum alloy, and Ti accounts for less than 0.1 weight percent of the rare earth aluminum alloy. Mixed RE accounts for 0.1 to 0.5 weight percent of the total weight of the rare earth aluminum alloy, and comprises 5 to 80 weight percent of lanthanum and 1 to 20 weight percent of yttrium. Besides the above elements, the rest component of the rare earth aluminum alloy is Al. By adding a certain amount of mixed rare earth, the thermal conductivity of the aluminum alloy, the plastic forming property and processing property of the alloy are improved.

Owner:李其真

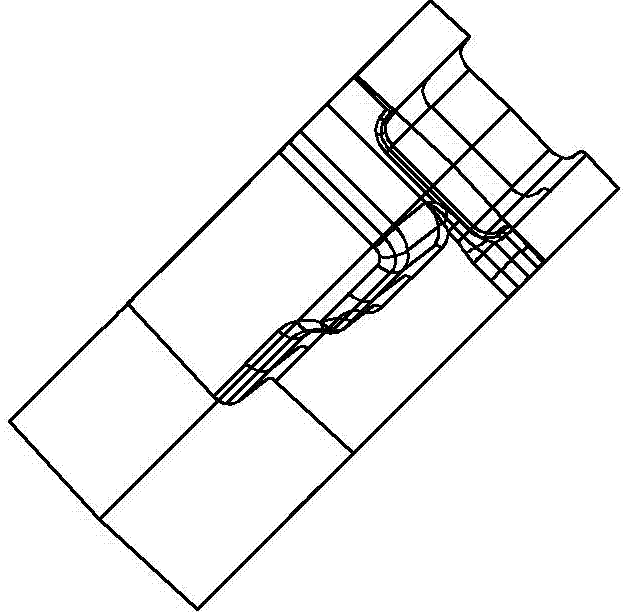

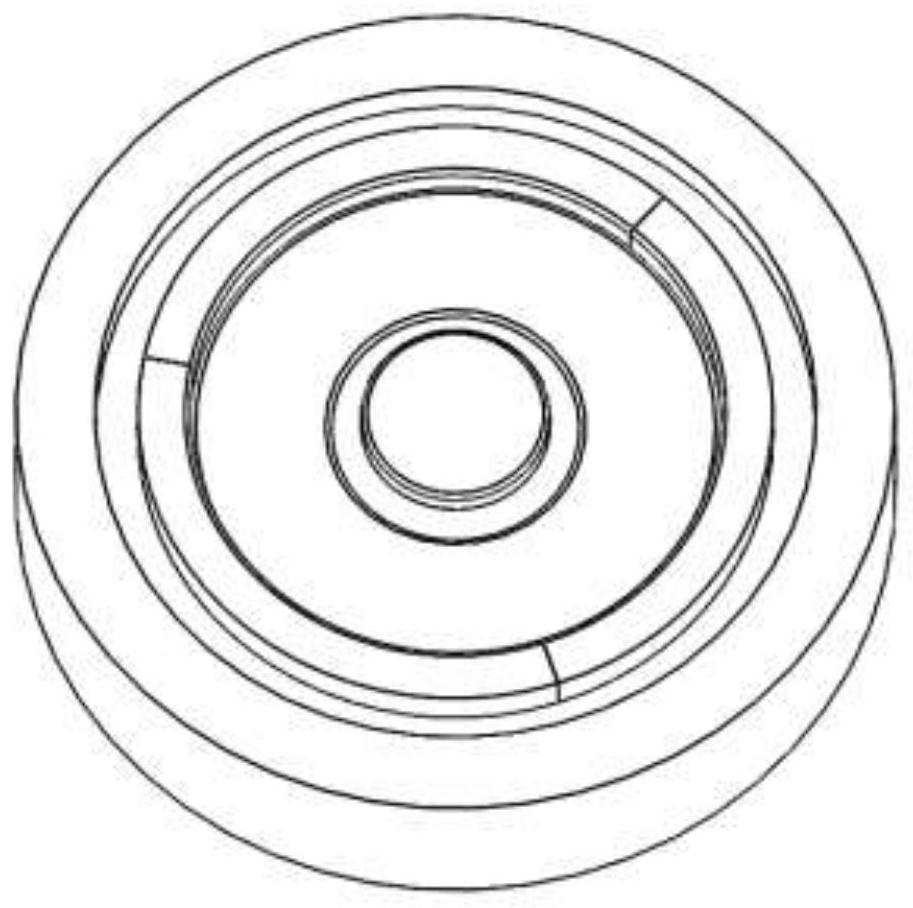

High-silicon aluminum alloy swash plate die-forging process and die

InactiveCN101628312AIncrease profitImprove mechanical propertiesForging/hammering/pressing machinesWheelsSiliconHeating temperature

The invention discloses a high-silicon aluminum alloy swash plate die-forging process, which realizes plastic forming of die forgings by a small flashing open type forging die. The die-forging process comprises the following steps: extruding a bar material, blanking, heating, die-forging plastic forming and post treatment, wherein the heating temperature of a blank is 500+ / -5 DEG C, and the preheating temperature of a concave die is 200+ / -5 DEG C; the small flashing die-forging process directly forges the heated aluminum alloy bar material to form swash plate die forgings with small flashing; the die is the small flashing open type forging die and consists of an upper convex die, a lower convex die and an extrusion cylinder; the concave die adopts a detachable structure; during ejecting, the die forgings are directly ejected from the lower convex die; the upper convex die is provided with annular even gaps of which height is 3 millimeters and thickness is 0.5 millimeter, namely flashing grooves; and the gradient of all surface withdrawing die contacted with the extrusion cylinder is less than or equal to 5 degrees. The process flow is reasonable, the process parameter and performance are stable, the die has a simple structure, the manufacture, assembly and use are convenient, and the work is reliable.

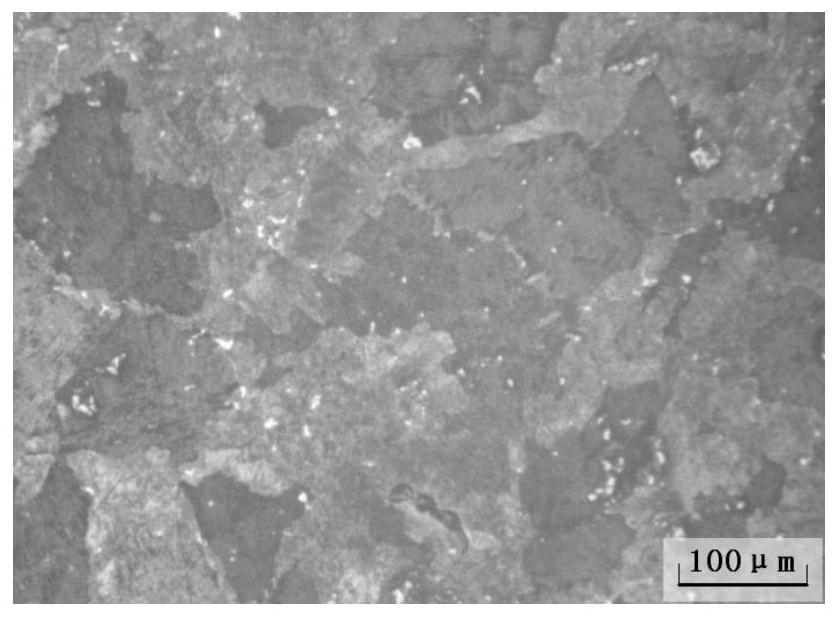

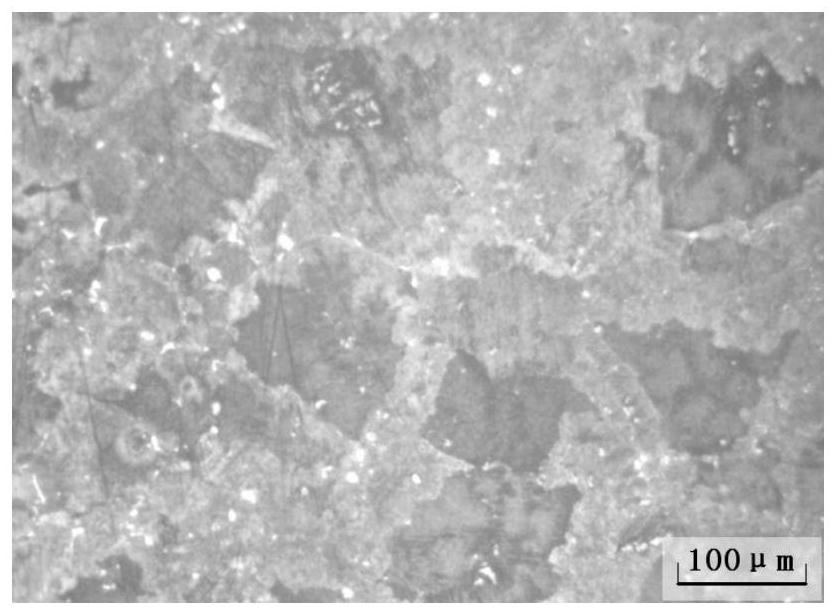

Heat machining and heat treatment process of aluminum-silicon alloy plate prepared by powder sintering

The invention discloses a heat machining and heat treatment process of an aluminum-silicon alloy plate prepared by powder sintering. The content of Si in an Al-Si alloy is controlled in a range of 10-40%; after a high-silicon aluminum alloy blank ingot obtained by sintering is uniformly annealed at 300-500 DEG C for heat forging with deformation of not more than 20%, the multi-pass hot rolling with the pass reduction of not more than 30% is performed; or the multi-pass hot rolling with the pass reduction of not more than 30% is directly performed for the blank ingot after homogenization in the step 2; and a product obtained by hot rolling is annealed to obtain the Al-Si alloy plate product. The prepared high-silicon-content aluminum-silicon alloy blank ingot is precise in component control, compact, and short in heat deformation and heat treatment process flow; and the obtained Al-Si alloy plate has such physical and mechanical performances as air tightness, heat conductivity, thermal expansion coefficient, tensile strength and bending strength needed by application of electronic packing materials, reduces the subsequent mechanical workload of the materials, and improves the utilization rate and the production efficiency of the materials.

Owner:HUNAN HYDRO DYNAMIC NEW MATERIAL CO LTD

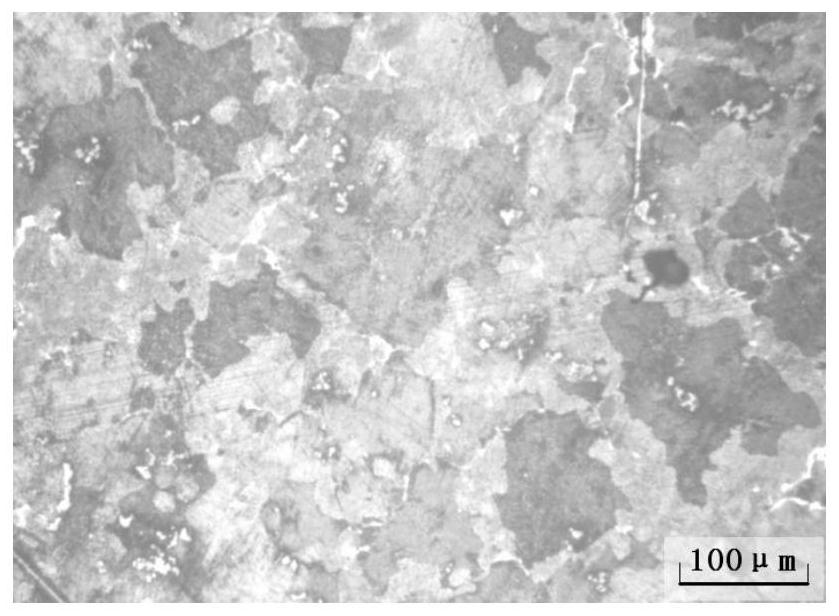

Preparation process of modified magnesium borate crystal whisker reinforced magnesium-matrix composite material

InactiveCN101705458AImprove interface binding stateImprove plastic forming abilityMagnesium matrix compositeVacuum pressure

The invention belongs to the technical field of new materials, in particular to a preparation process for modifying and optimizing magnesium alloy matrix and reinforcing the interphase contact surface and interface aiming at the magnesium borate crystal whisker reinforced magnesium-matrix composite material. The study proves that no obvious interface reaction occurs at the interface of the magnesium borate crystal whisker and the magnesium matrix, and the bonding strength of the interface is not high. By adopting the invention, the interface of the crystal whisker reinforced magnesium-matrix composite material reaches a better bonding state, and the performance of the magnesium borate crystal whisker reinforced magnesium-matrix composite material is improved. The preparation process comprises steps of coating the magnesium borate crystal whisker, preparing the modified magnesium borate crystal whisker prefabricated block, preparing cast composite ingot blank by a vacuum pressure infiltration method; and thermally extruding the ingot blank. The composite material comprises components of aluminium isopropoxide Al(OC3H7)3, distilled water, muriatic acid, magnesium borate crystal whisker, magnesium and the balance of magnesium alloy.

Owner:QINGHAI UNIVERSITY

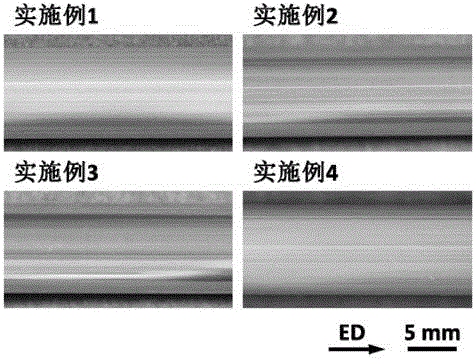

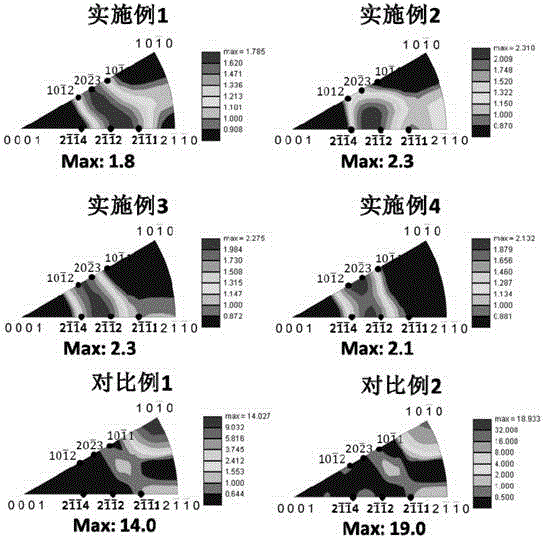

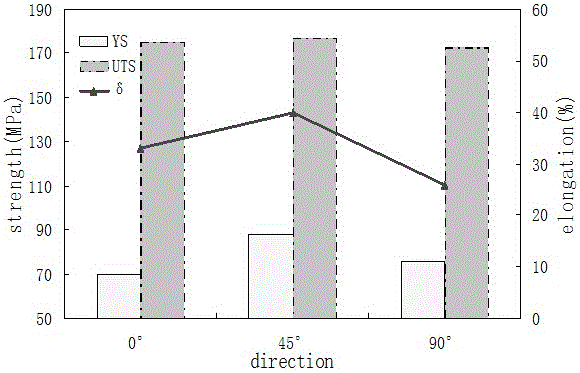

Low-cost high-speed-extruded magnesium alloy material and preparation process thereof

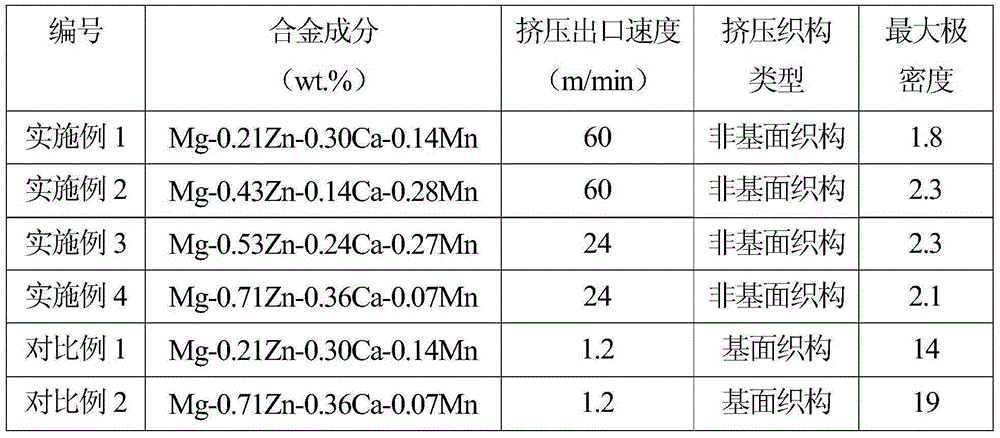

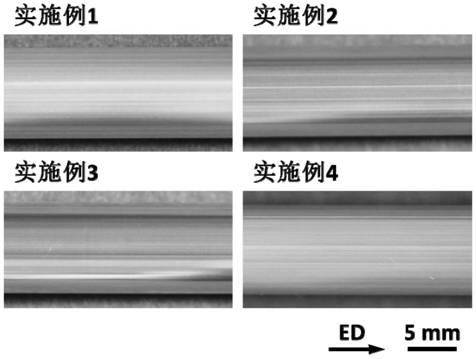

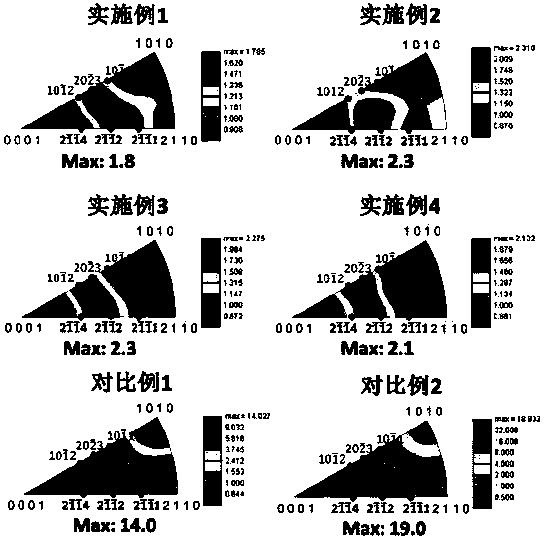

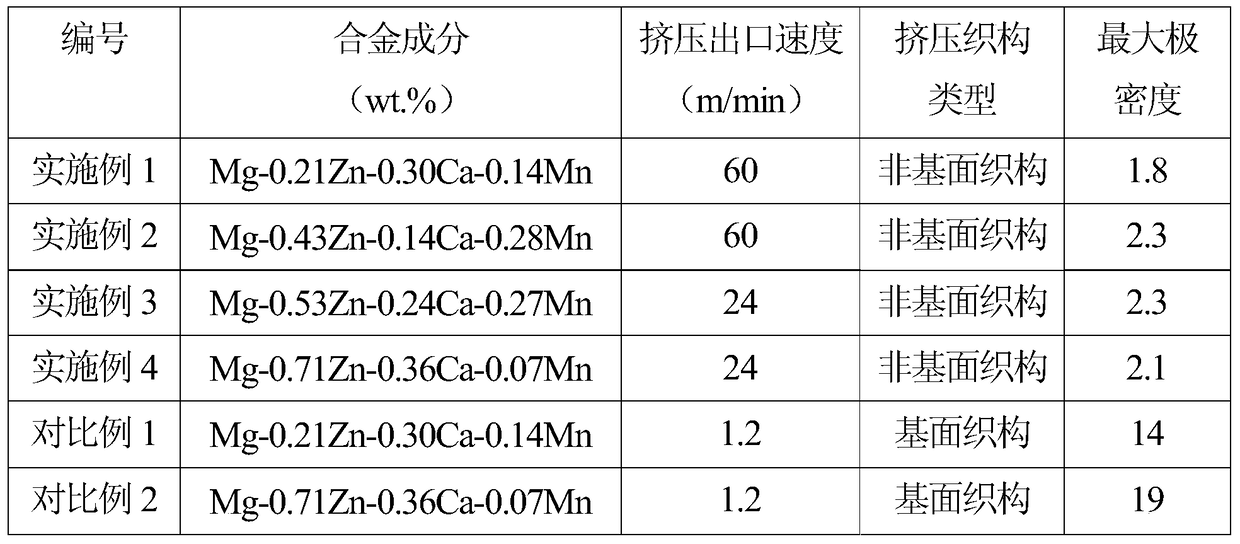

The invention discloses a low-cost high-speed-extruded magnesium alloy material and a preparation process thereof and belongs to the technical field of metal materials. The extruded material comprises the following chemical components by weight percent: 0.1-0.9% of Zn, 0.1-0.5% of Ca, 0-0.5% of Mn and the balance Mg and inevitable impurities, wherein the total content of the alloy elements (Zn, Ca and Mn) does not exceed 1.5 wt%. Production is performed at the extrusion outlet speed of more than or equal to 24 m / min, the extrusion production efficiency is high, the cost of the extruded material is lowered, the extruded material is smooth in surface and has no surface cracks, and therefore, the yield of the extruded material is guaranteed; and meanwhile, the extruded material has a weak non-basal texture with the maximum density value of less than or equal to 4. The extruded material is low in content of alloy elements, does not contain rare earth elements or other noble metal elements, and therefore, is low in cost.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Room-temperature high-plasticity wrought magnesium alloy and preparation method thereof

ActiveCN103866169AMeet the needs of plastic processingIncrease productivitySmelting processGrain structure

The invention provides room-temperature high-plasticity wrought magnesium alloy and a preparation method thereof. The magnesium alloy comprises the following components by weight percent: 5.5wt%-7.3wt% of Al, 0.40wt%-1.50wt% of Zn, 0.15wt%-0.50wt% of Mn, 0.05wt%-1.0wt% of P and the balance being Mg and inevitable impurities, wherein the inevitable impurities comprise the following components: not more than 0.05wt% of Si, not more than 0.004wt% of Fe, not more than 0.004wt% of Cu and not more than 0.002wt% of Ni. According to the magnesium alloy, a nonmetal element P is added in an existing magnesium alloy smelting process, a stable small grain structure is obtained under the action of the nonmetal element P, the room-temperature plasticity is improved, and the room-temperature processing and using requirements of finished products or semi-finished products can be met.

Owner:SUZHOU KAI YOU ELECTRONICS SCI & TECH LTD

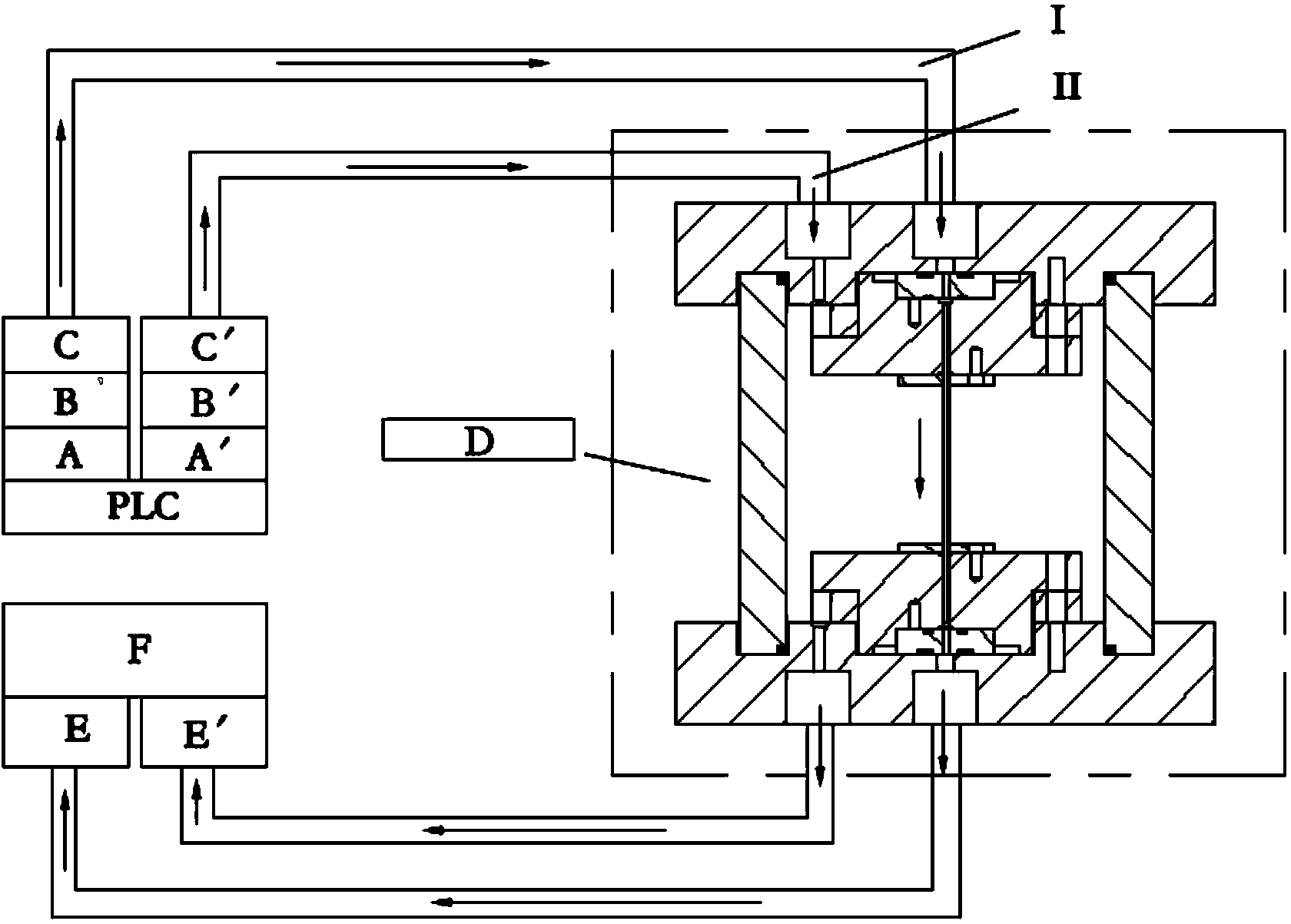

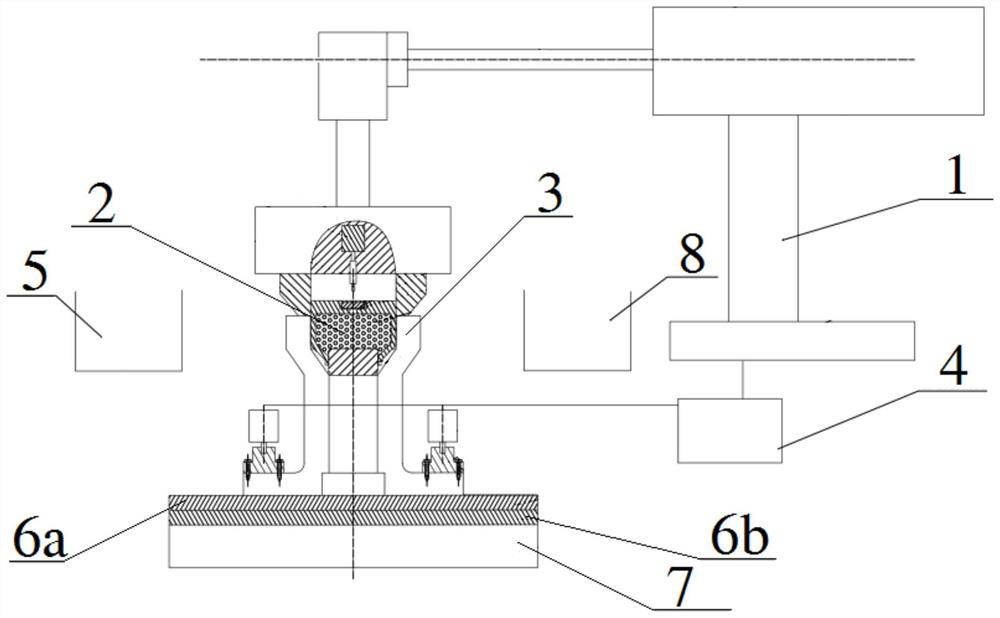

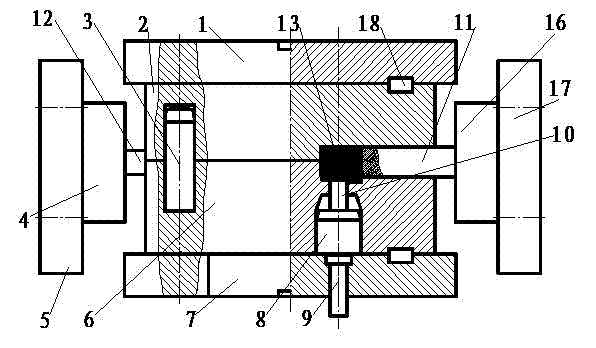

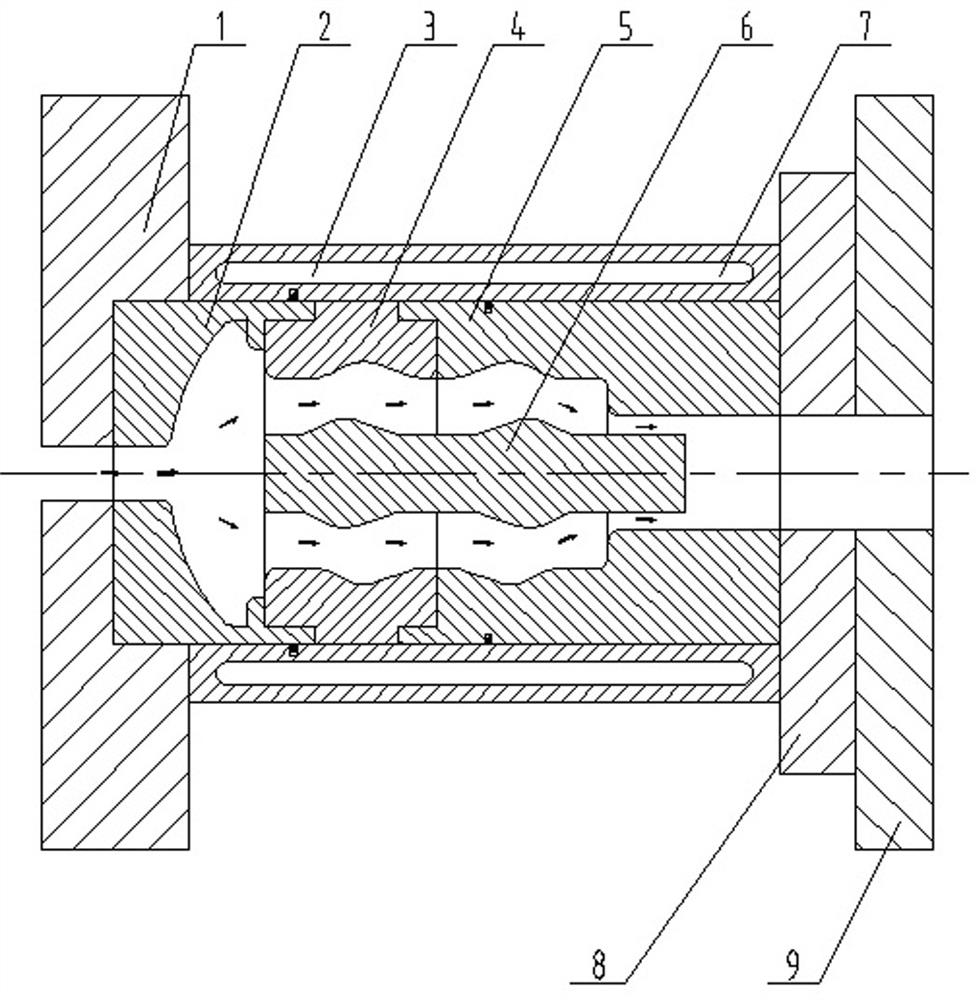

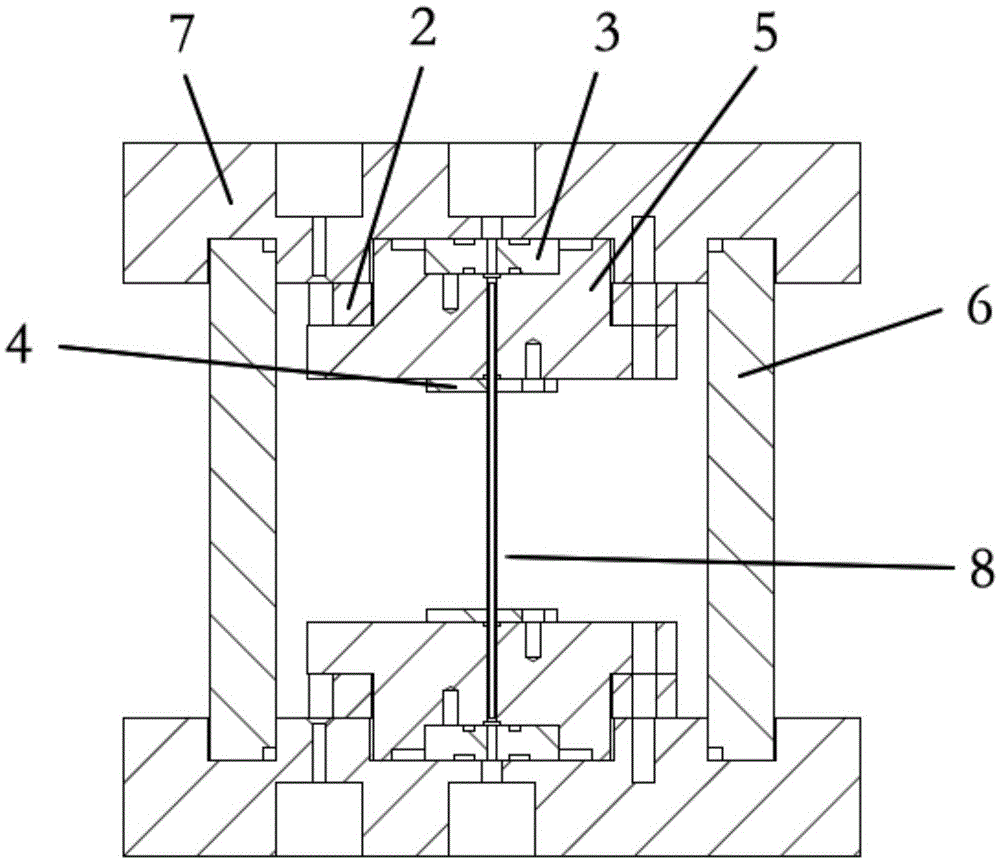

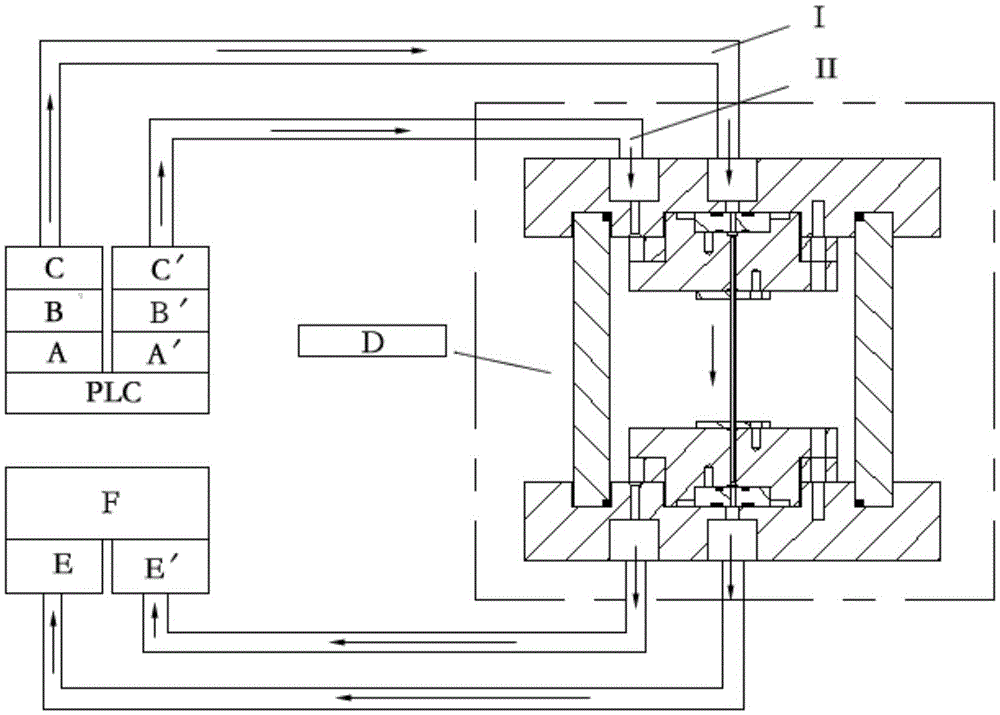

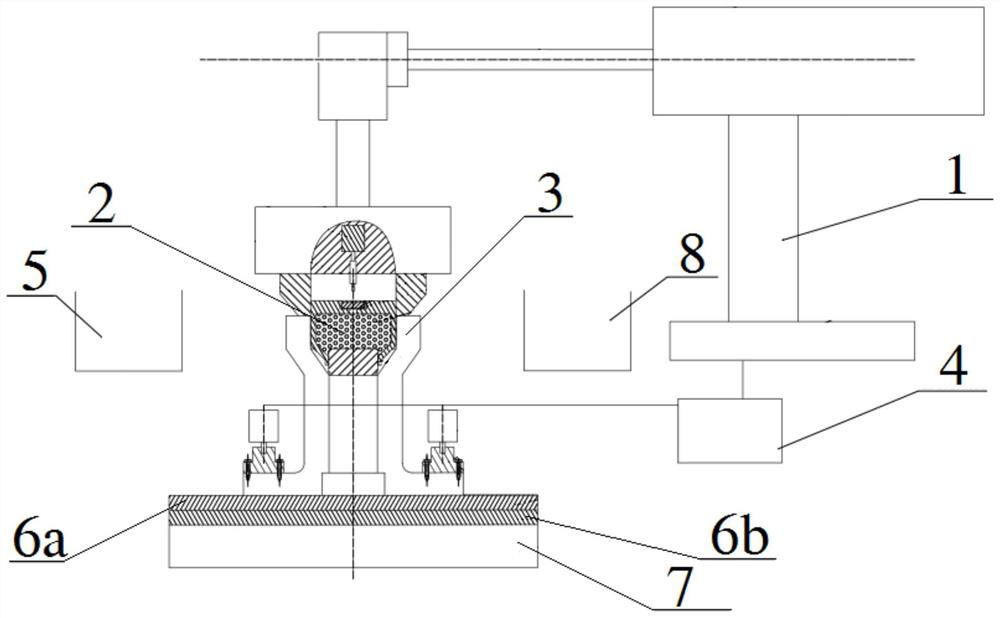

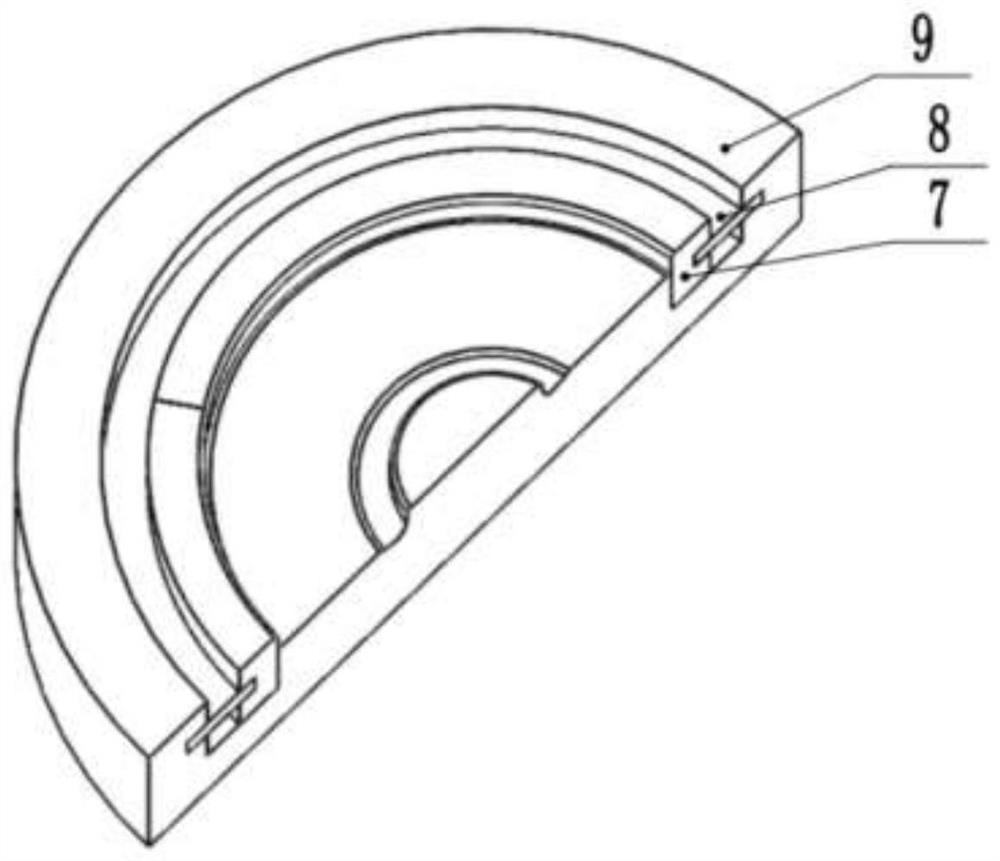

Miniature pipe two-way hydraulic forming device

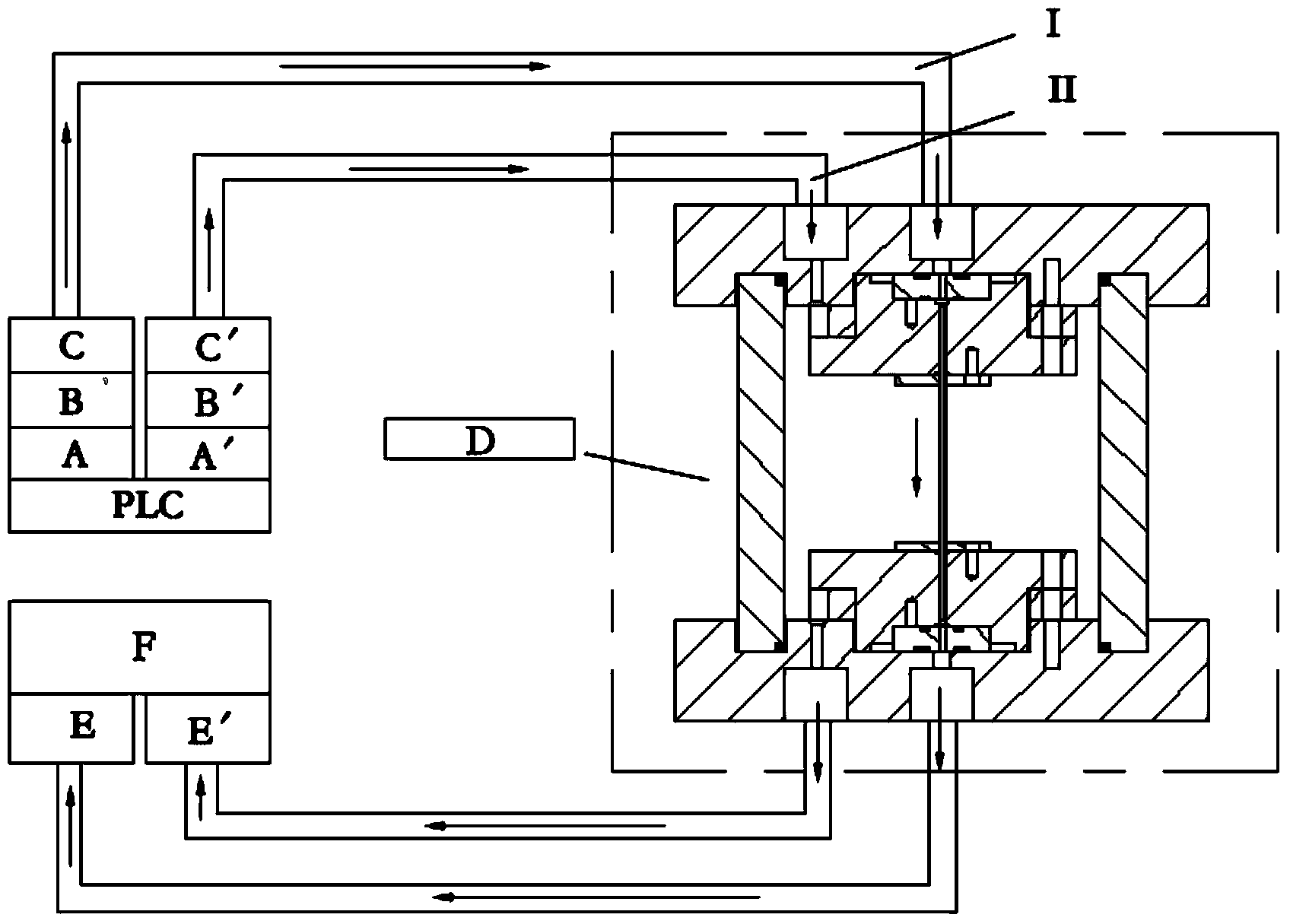

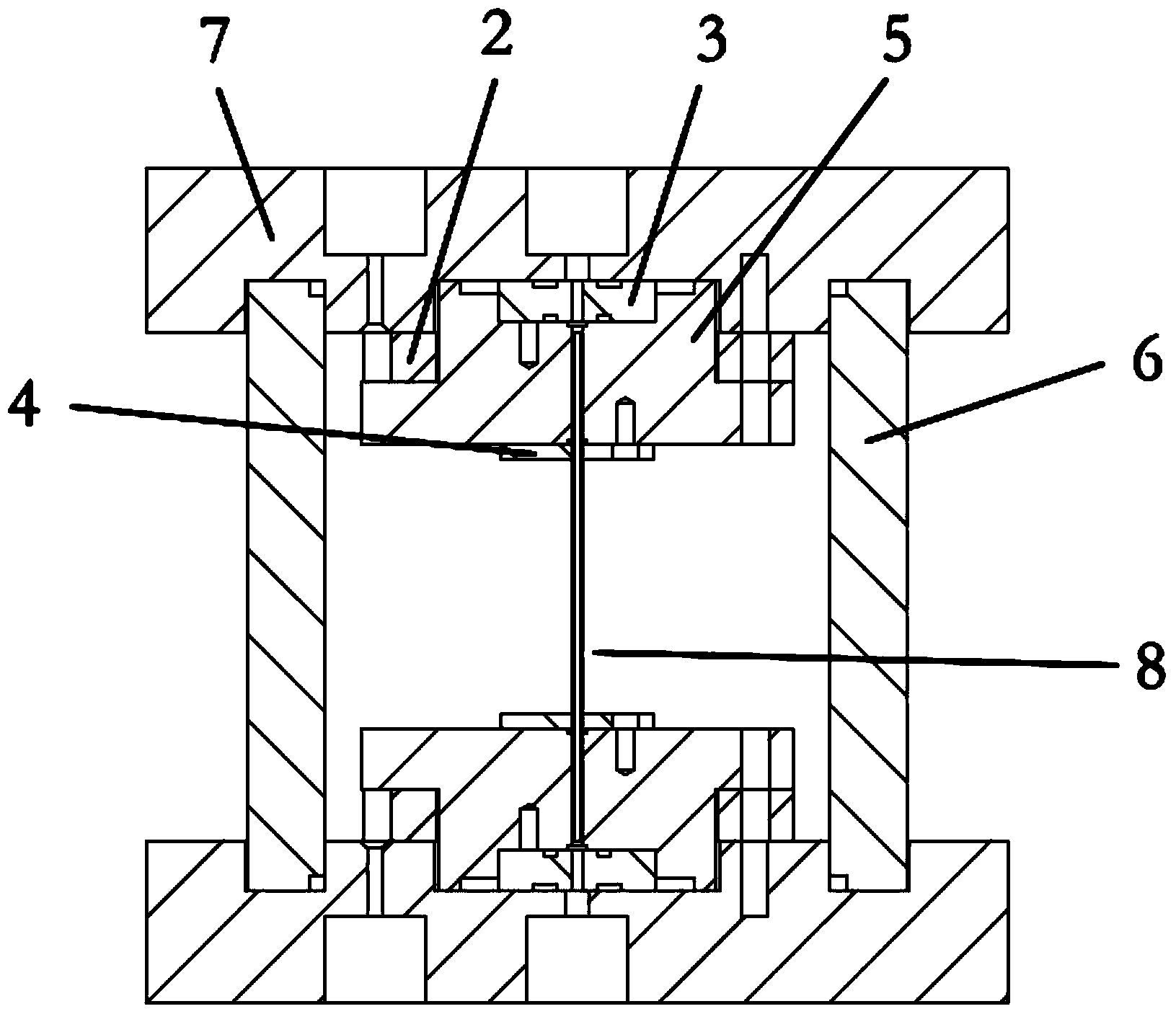

InactiveCN104226779AImprove plastic forming abilityAvoid connectionInternal pressureProgrammable logic controller

The invention discloses a miniature pipe two-way hydraulic forming device, which comprises a PLC (programmable logic controller) control module, an inner-pressure pressure pump, an outer-pressure pressure pump, an inner-pressure pressure booster, an outer-pressure pressure booster, an inner-pressure one-way valve, an outer-pressure one-way valve, an inner-pressure high-pressure needle valve, an outer-pressure high-pressure needle valve and an oil tank forming mold, wherein the forming mold comprises a guide block, a cylinder casing, an embedding block, an edge pressing ring and a sealing block. The miniature pipe two-way hydraulic forming device has the advantages that the pressure can be simultaneously exerted on the inner and outer surfaces of a miniature pipe, the miniature pipe is driven to be formed through pressure difference, the generation and the increase of tiny cracks inside the miniature pipe and the generation of nucleation can be prevented through the introduction of back pressure, further, the plastic forming capability of the miniature pipe is greatly improved, in addition, the sealing design is reasonable, the sealing performance is greatly improved, the PLC control is more precise and more reliable, and the response speed is higher.

Owner:NANJING UNIV OF SCI & TECH

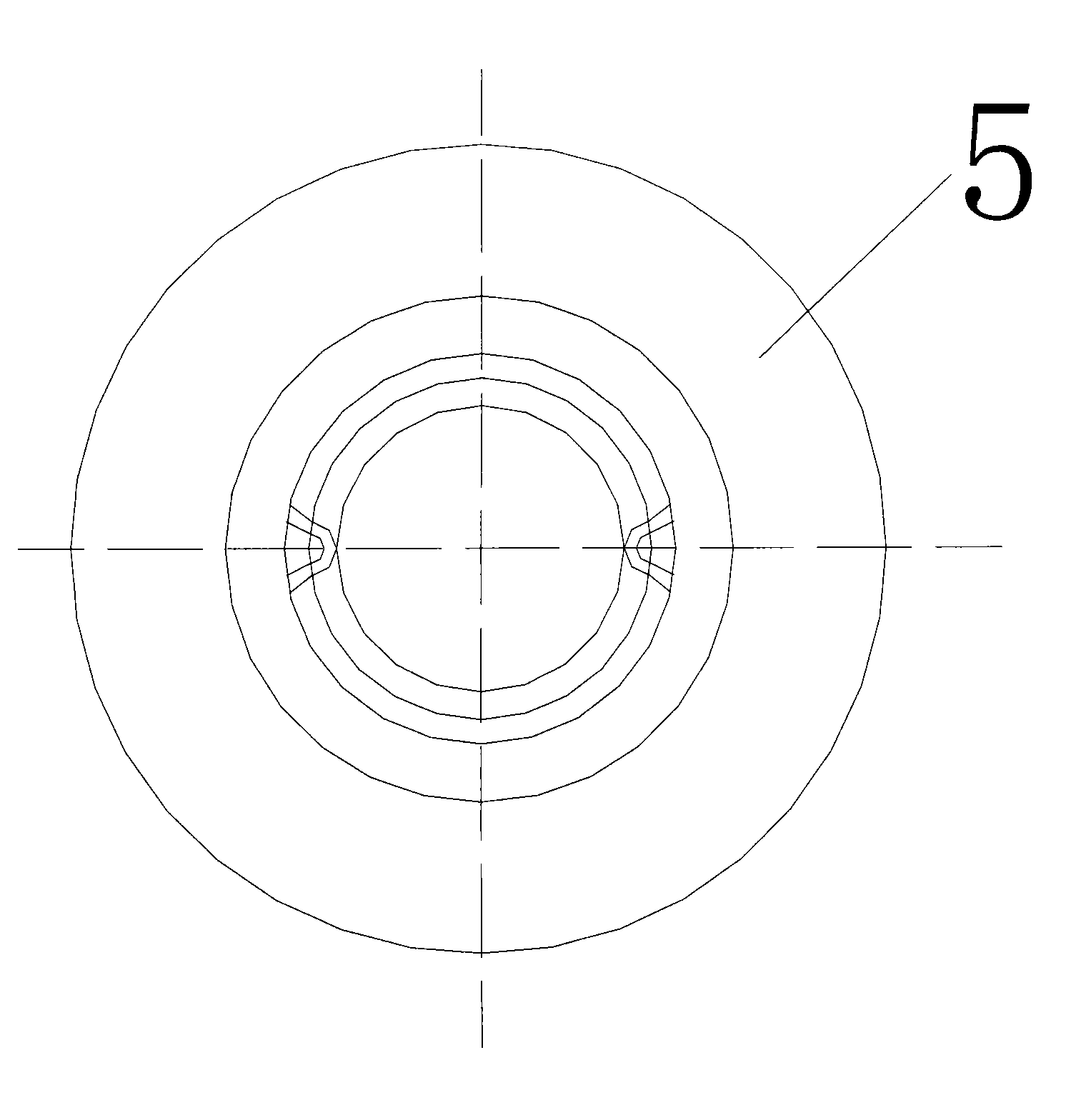

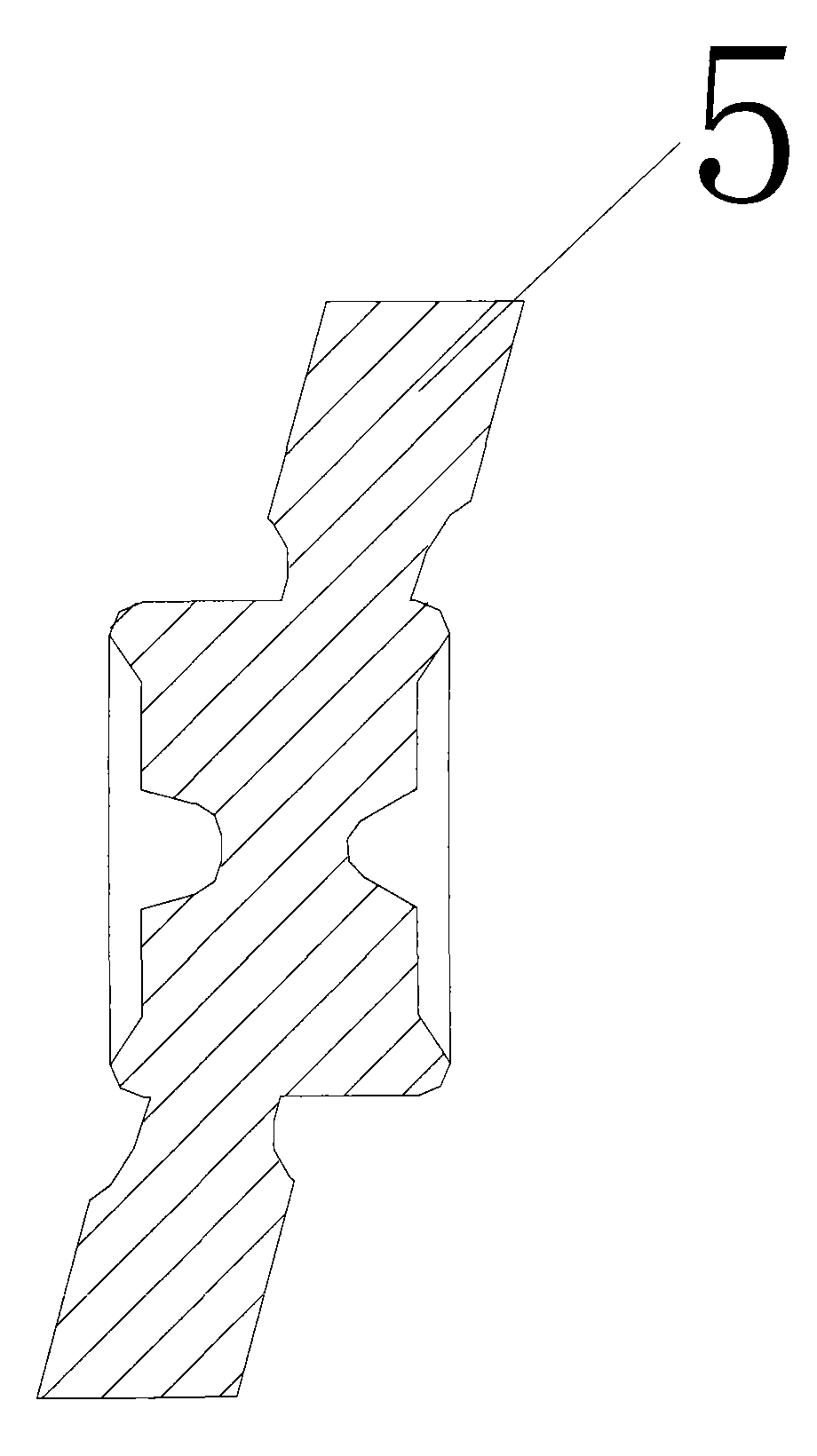

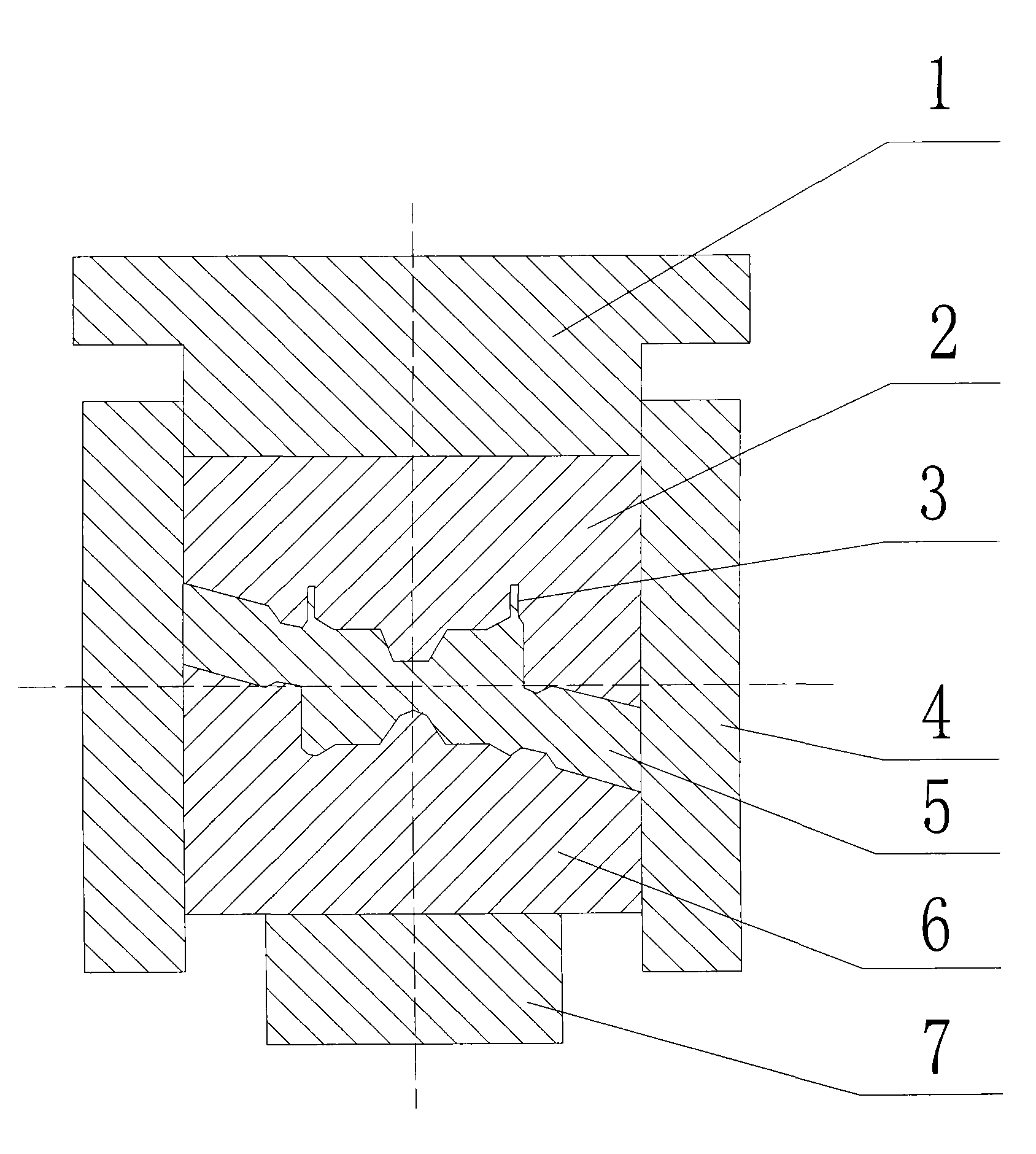

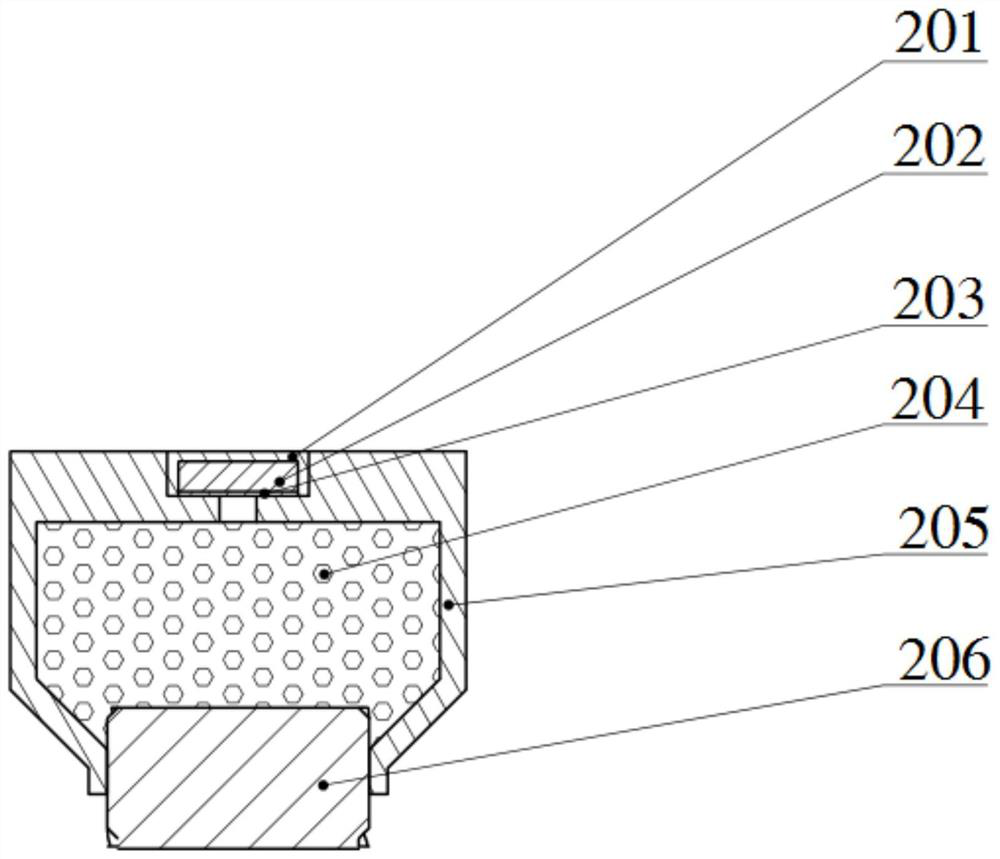

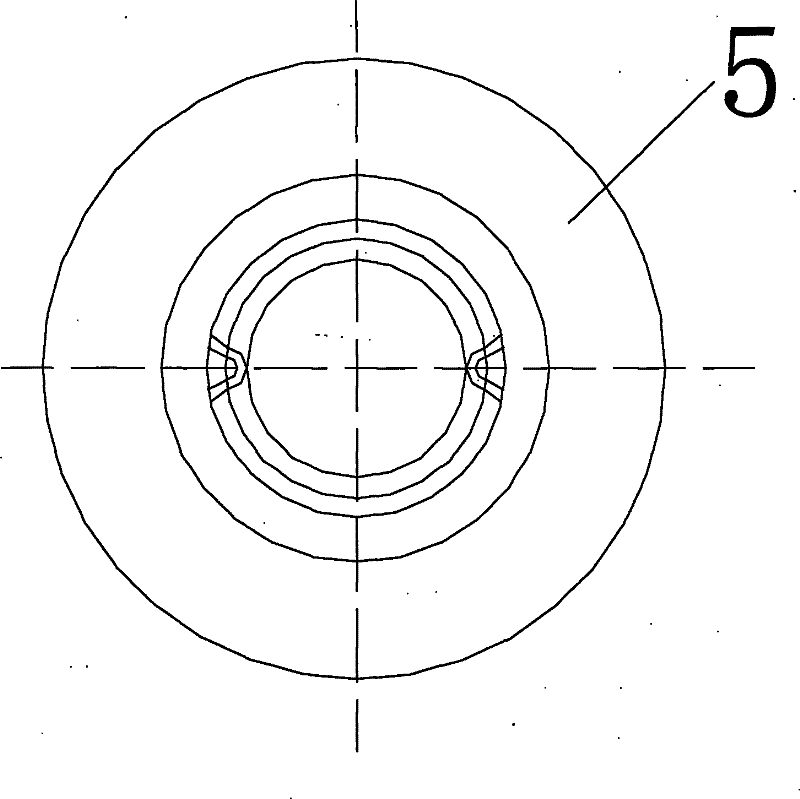

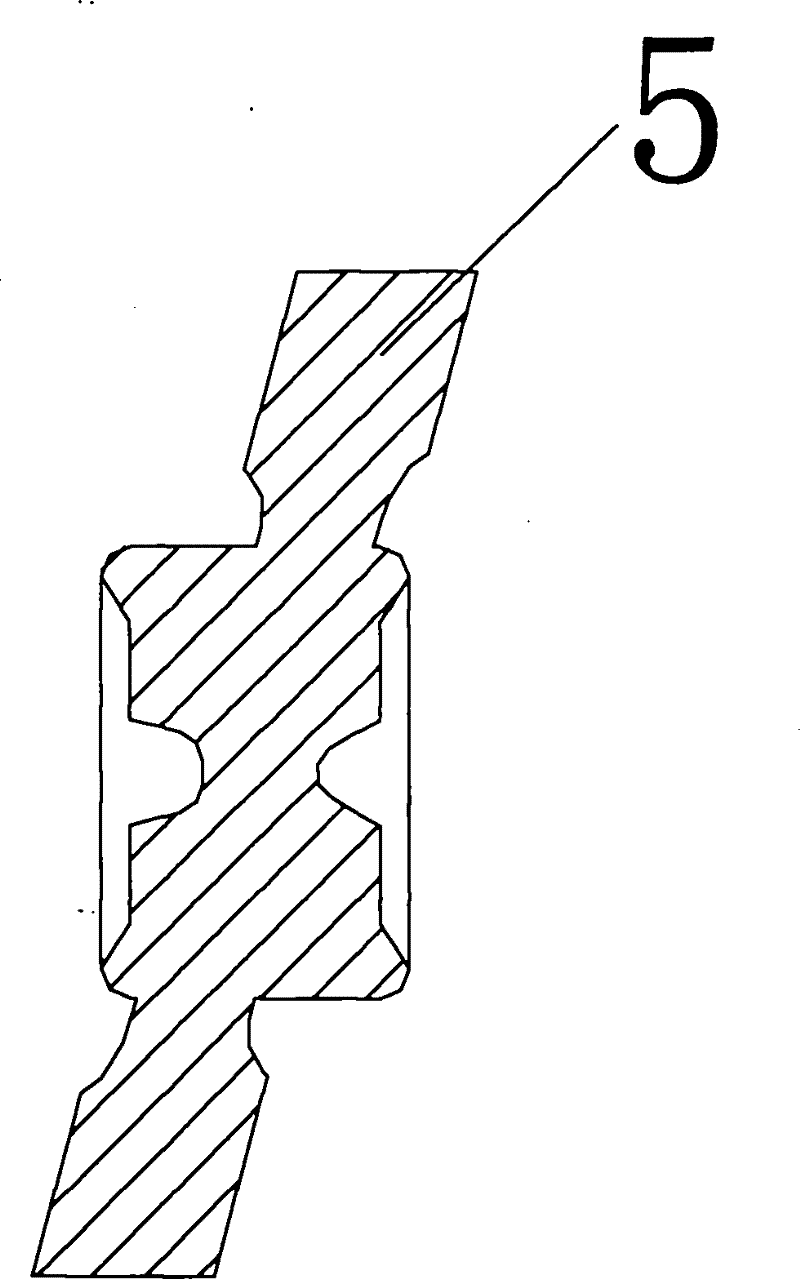

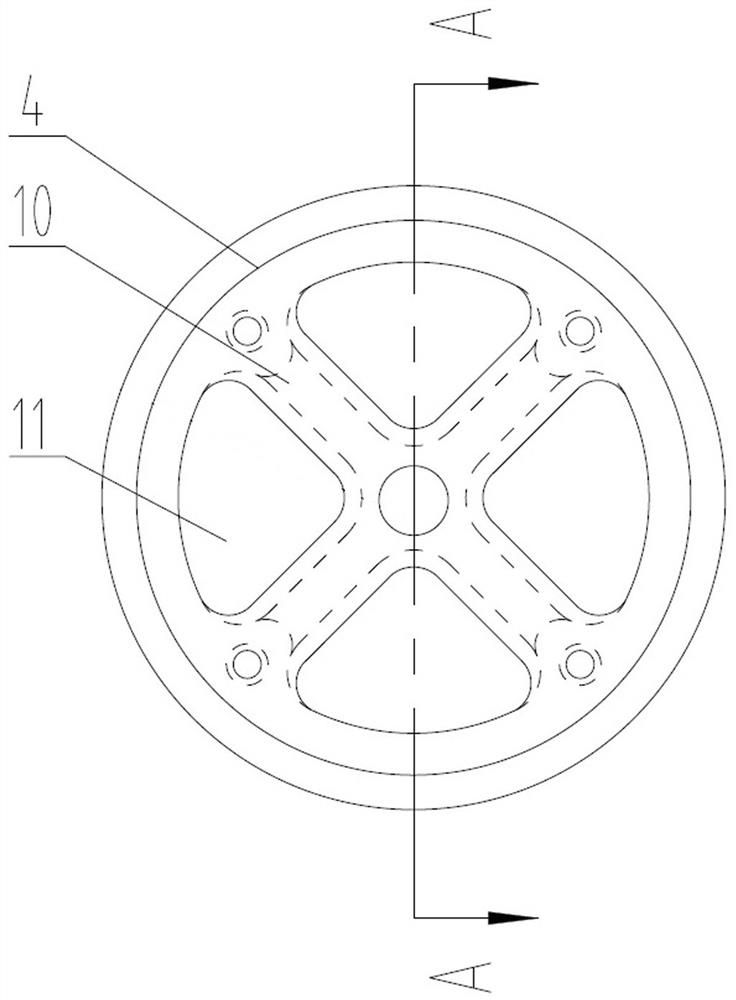

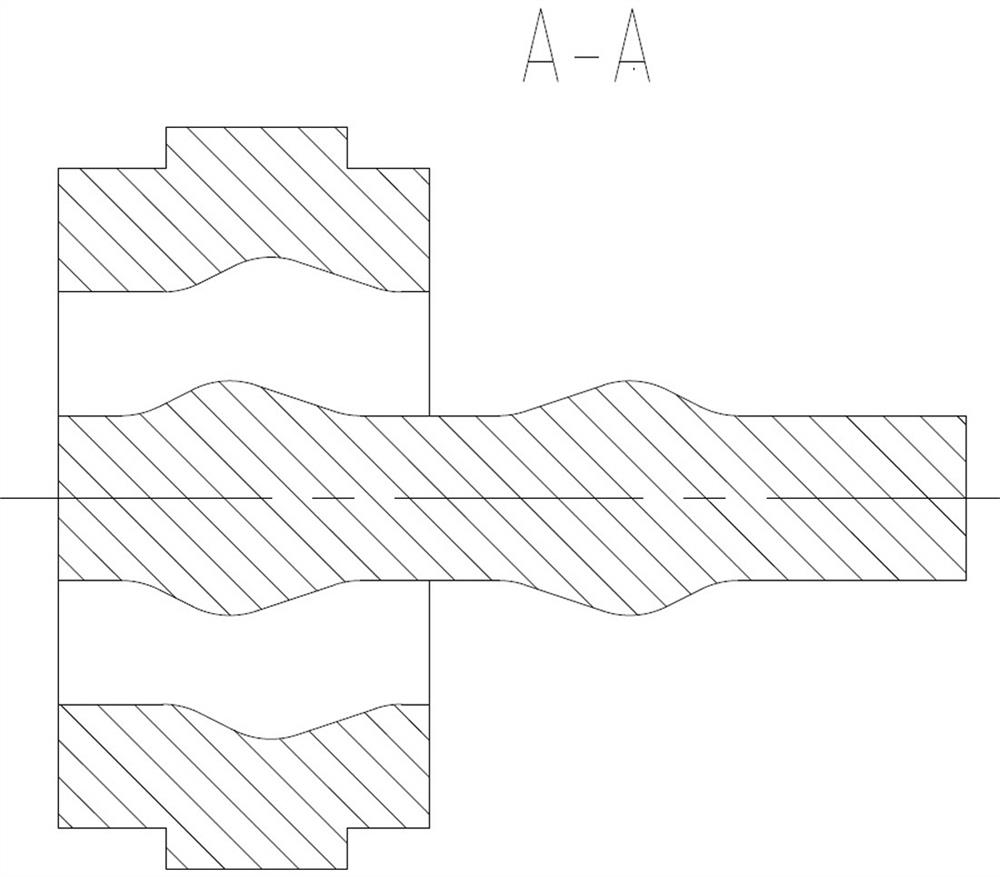

Miniature pipe two-way hydraulic forming mold

The invention discloses a miniature pipe two-way hydraulic forming mold, which comprises a guide block, a cylinder casing, an embedding block, a blank holder and a sealing block, wherein the pressure can be simultaneously exerted on the inner surface and the outer surface of a miniature pipe, the miniature pipe is driven to be formed through the pressure difference, the generation and the growth of tiny cracks inside the miniature pipe and the occurrence of nucleation can be prevented, and further, the plastic forming capability of the miniature pipe can be greatly improved. In addition, one O-shaped sealing ring is respectively arranged on each of two end surfaces of the sealing block, the sealing performance is greatly improved, high-pressure liquid with the pressure intensity as high as 350MPa can be sealed, meanwhile, the high-pressure liquid inside and outside the miniature pipe can also be isolated, and the communication of inside and outside high-pressure liquid can be avoided; in addition, the O-shaped sealing ring is additionally arranged between the embedding block and the blank holder, and the communication of outside high-pressure liquid with the inner pressure through the embedding block is prevented.

Owner:NANJING UNIV OF SCI & TECH

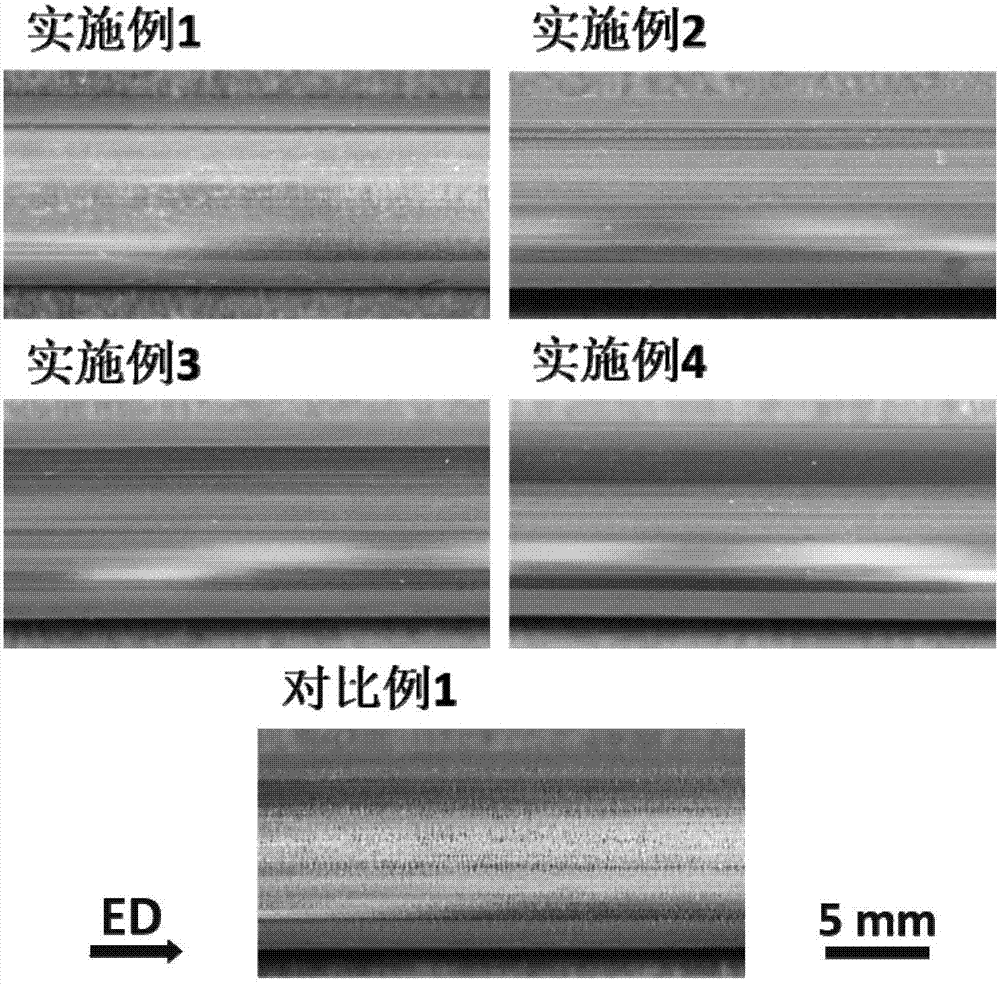

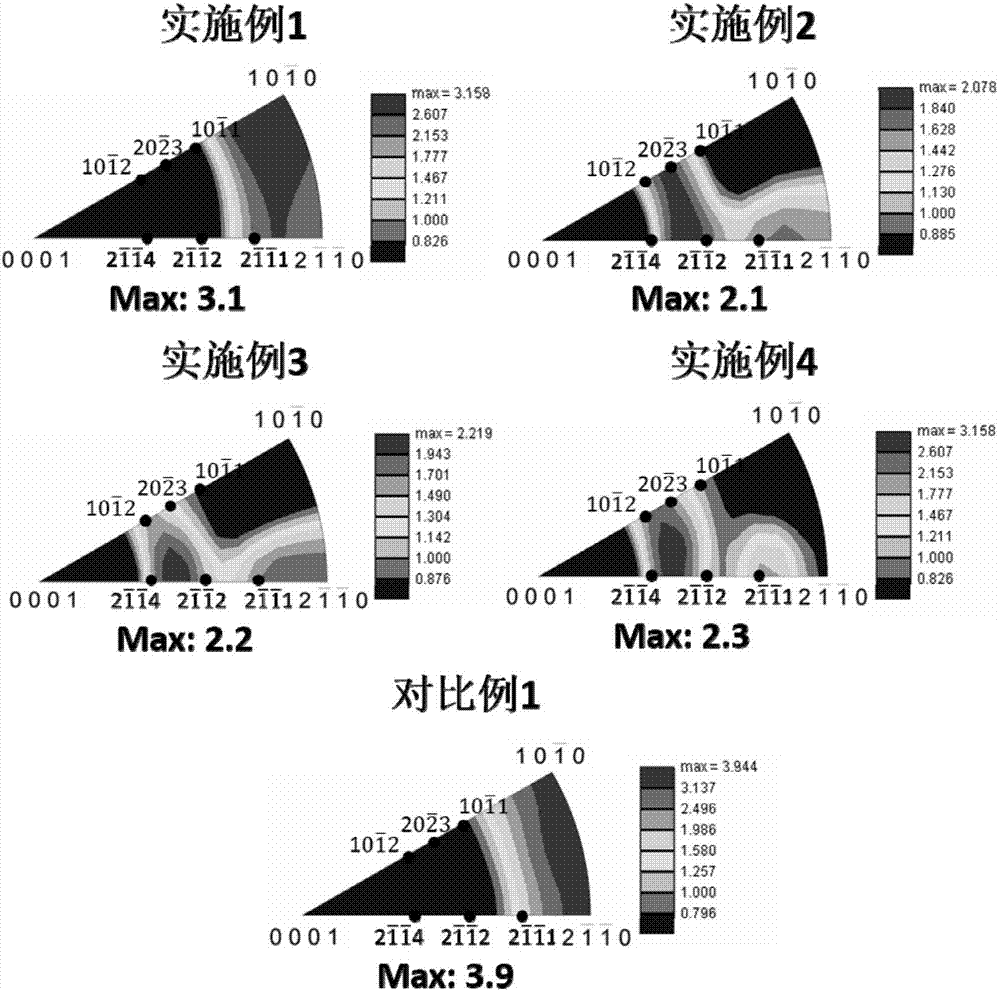

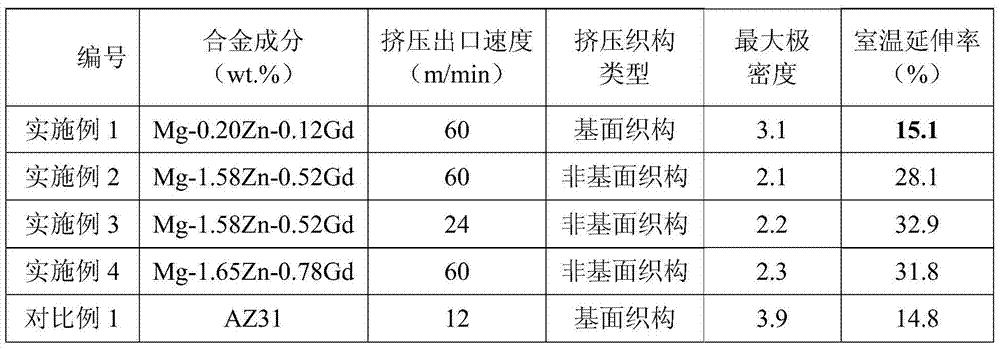

High-speed extruded magnesium alloy deformed profile low in rare earth content and preparation technique thereof

The invention discloses a high-speed extruded magnesium alloy deformed profile low in rare earth content and a preparation technique thereof, and belongs to the technical field of metal materials. The magnesium alloy comprises, by weight, 0.1-2.0% of Zn, 0.1-0.9% of RE, and the balance Mg. A trace of or a small amount of rare earth (RE) is added into the magnesium alloy, and the alloy cost is effectively reduced. Production is conducted with the speed of an extrusion outlet larger than 24 m / min, the extrusion production efficiency is high, the cost of the extruded profile is reduced, the surface of the obtained extruded profile is smooth and free of cracks, and the yield of the extruded profile is guaranteed. Meanwhile, the obtained extruded profile might have weak basal textures or weak non-basal textures, and the maximum pole density value of the weak basal textures or the weak non-basal textures is smaller than or equal to 4; and through optimized constituents, the room-temperature elongation of the extruded profile can be larger than or equal to 25%.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

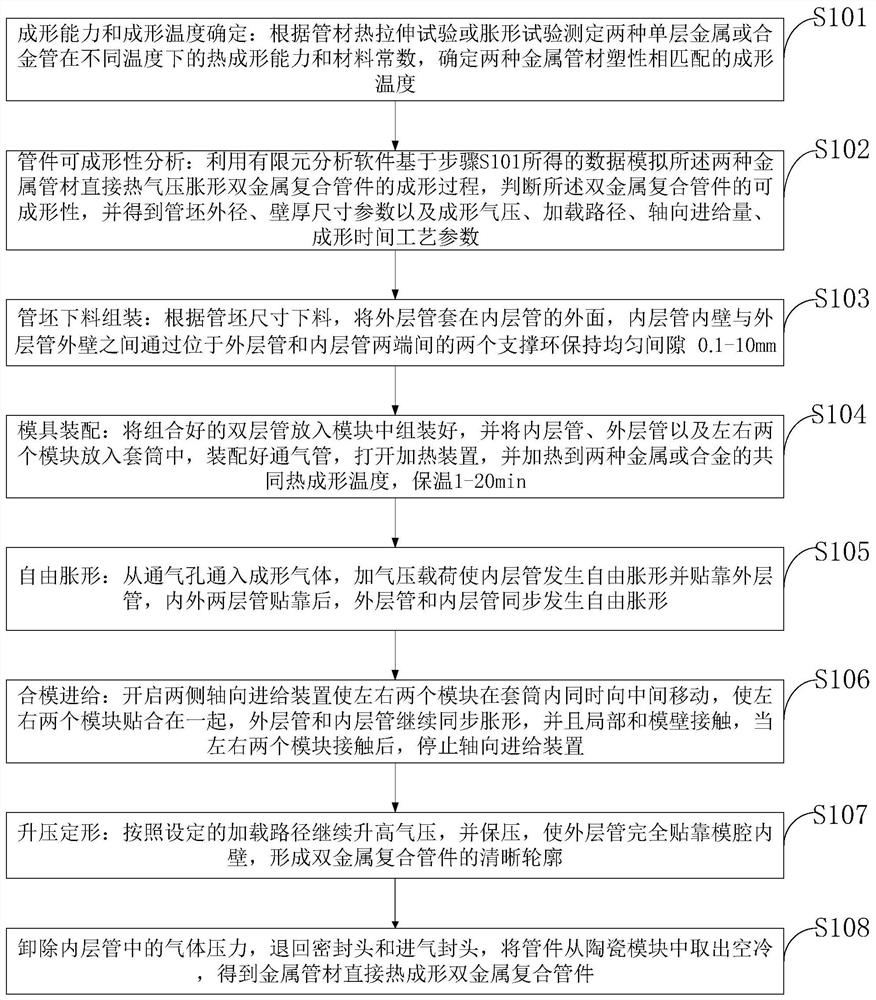

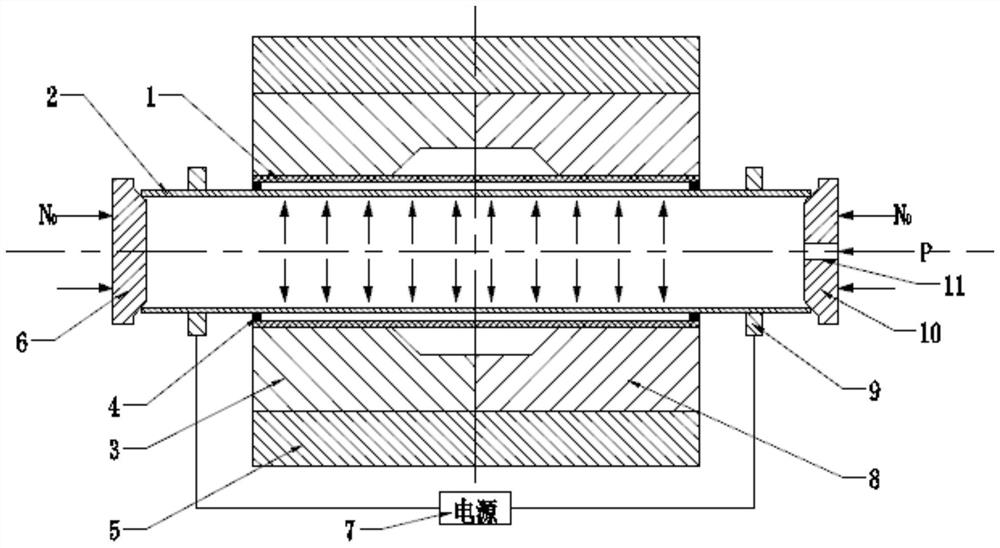

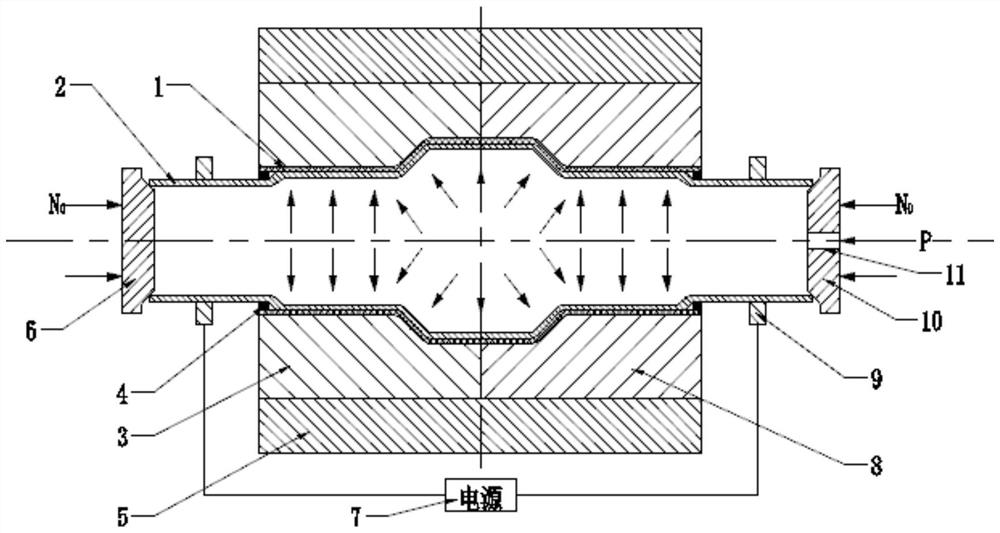

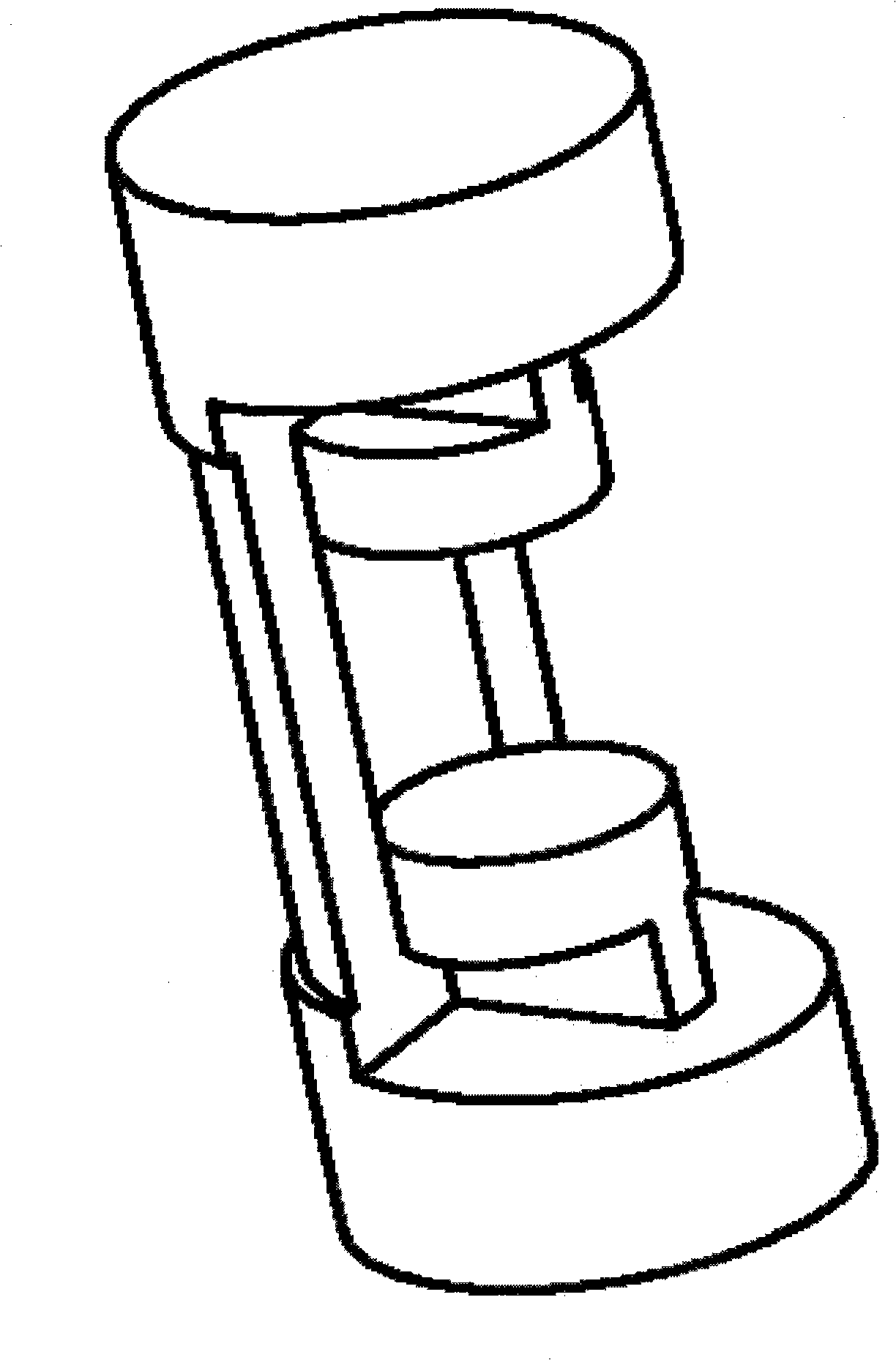

Method and device for directly hot-forming bimetal composite pipe fitting from metal pipe

The invention belongs to the technical field of bimetal composite pipe fittings and discloses a method and a device for directly hot-forming a bimetal composite pipe fitting from a metal pipe. The forming capacity and the forming temperature are determined, the formability of the pipe fitting is analyzed, and a pipe blank is subjected to blanking and assembly. Blanking is conducted according to the available pipe blank size, an inner-layer pipe sleeves an outer-layer pipe, and a uniform gap of 0.1-10 mm is kept between the inner wall of the inner-layer pipe and the outer wall of the outer-layer pipe through two supporting rings located between the two ends of the outer-layer pipe and the two ends of the inner-layer pipe; a die is assembled, free bulging is conducted, die assembly and feeding are performed, boosting pressure and shaping are performed, unloading is performed, and a part is picked up. The bimetal composite pipe fitting is obtained. An air pressure bulging method is adopted, the process is simple, and compounding and forming of the bimetal composite pipe fitting difficult to deform at the room temperature can be achieved at the same time through a single process. The deformation resistance of the pipe at high temperature is small, the plastic forming performance is high, and large plastic forming of materials difficult to deform can be achieved. The bimetal composite pipe fitting is combined through cold shrinkage, and the combination is reliable.

Owner:HARBIN INST OF TECH AT WEIHAI

Silumin piston contour forging technique and mold

InactiveCN101254517ASimple structureImprove mechanical propertiesForging/hammering/pressing machinesPistonsSiluminPilot hole

The invention discloses a die-forging process for high-silicon aluminum alloy pistons and forging die. The process can directly mold a high-silicon aluminum alloy extrusion bar blank in one step into a piston forging piece heated up to 400-470 DEG C which has a transversal flash edge of a thickness no more than 1.2 mm along the die parting surface, and the piston forging is obtained after cutting the flash edge. The forging die comprises an upper die and a lower die. The die cavity of the lower die is provided circumferentially with a flash edge groove that consists of a bridge portion and a storage portion. The width / thickness ratio of the bridge portion close to the die cavity is 8-10. The upper and the lower dies are guided and positioned based on the engagement of two pilot pins and the corresponding pilot holes. The forging die is mounted to work on a high-speed hydraulic press (4000KN). The inventive process has the advantages of good stability, simple die structure and easy operation.

Owner:WENLING LIHUA MASCH CO LTD

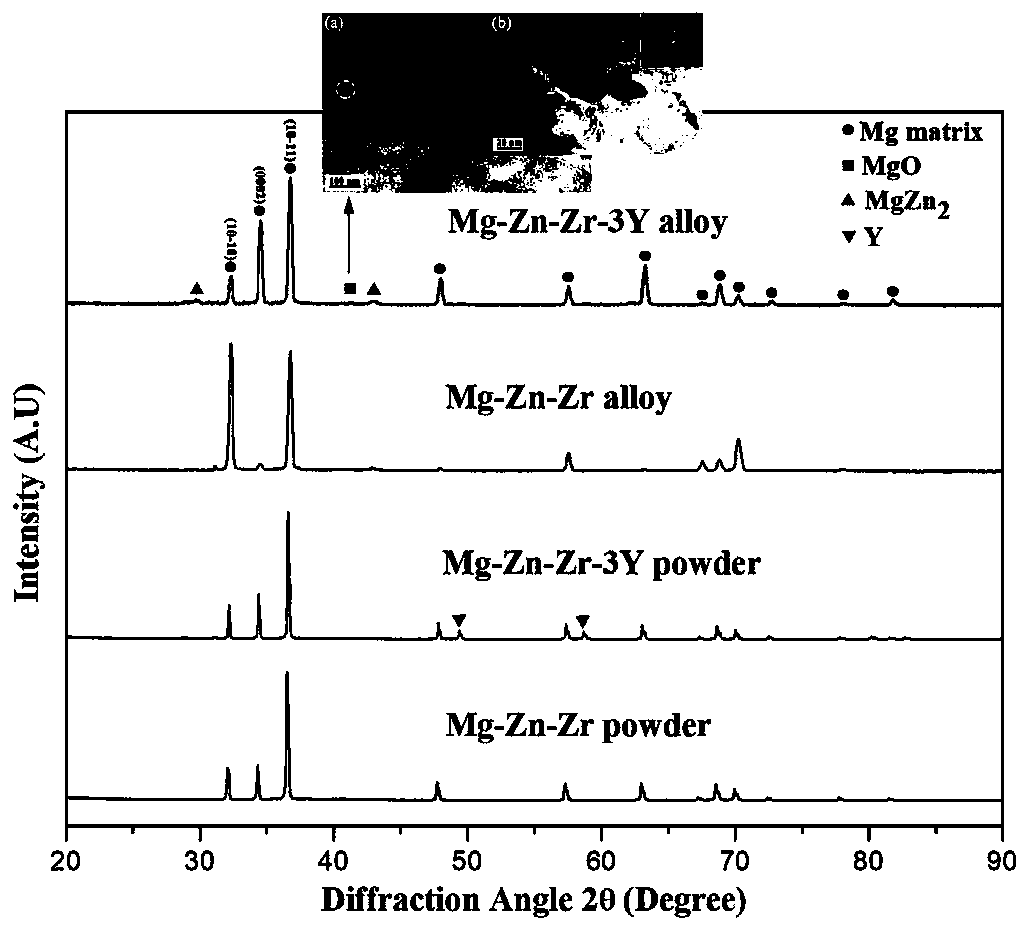

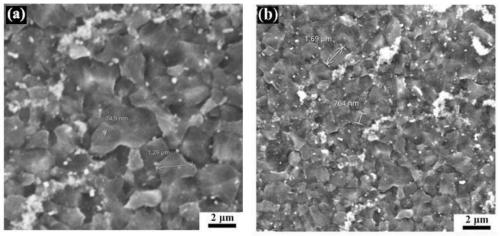

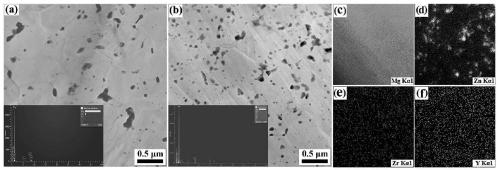

Y-doped Mg alloy and preparation method thereof

The invention discloses a Y-doped Mg alloy. The Y-doped Mg alloy is composed of Mg, Zn, Zr and Y and comprises, by mass, 4.9-5.5% of Zn, 0.16-0.19% of Zr, 2.9-3.2% of Y, and the balance Mg and inevitable impurities. A preparation method of the Y-doped Mg alloy comprises the steps of (1) preparation of alloy powder, specifically, adding ethyl alcohol to Mg-Zn-Zr powder and Y powder, adding zinc stearate, conducting vacuum pumping, and conducting ball milling to obtain the alloy powder; (2) sintering, specifically, feeding the alloy powder into a vacuum hot pressing sintering furnace, and conducting vacuum pumping, heating sintering and cooling to obtain an alloy billet; and (3) hot extrusion, specifically, conducting heat preservation, feeding the alloy billet into an extrusion die for extrusion and then obtaining the Y-doped Mg alloy. According to the Y-doped Mg alloy and the preparation method thereof, the rare earth element Y is subjected to solid solution to go into a Mg base body to promote formation of an alloy double-peak crystal structure, grain refinement, generation of high-melting-point hard phases and the like. On the premise of ensuring the strength, the toughness and plastic formability of the Mg alloy are improved, and a certain reference basis is provided for actual application of the Y-doped Mg alloy.

Owner:QINGHAI UNIVERSITY

Spiral rivet lock welding device and method for explosive shock forming

ActiveCN111659845AGood mechanical propertiesImprove mechanical propertiesRivetsSheet joiningElectrical connectionManufacturing engineering

The invention provides a spiral rivet lock welding device for explosive shock forming. The spiral rivet lock welding device comprises an implementation mechanism, rivet units, a guide edge pressing mechanism and a controller. The rivet units are stored in a rivet box in a centralized manner. The implementation mechanism can move and is used for taking the rivet units from the rivet box, placing the rivet units on the guide edge pressing mechanism and triggering the rivet units. The guide edge pressing mechanism is pressed on an upper plate and a lower plate in advance and used for pressing theupper plate and the lower plate on a flat die. The controller is electrically connected with the implementation mechanism and the guide edge pressing mechanism respectively and used for controlling movement of the implementation mechanism and pressing of the guide edge pressing mechanism. The invention further provides a spiral rivet lock welding method for explosive shock forming. The spiral rivet lock welding device is reasonable in structural design and high in operation automation degree, plate connection can be efficiently completed, the connecting point precision is high, the mechanicalperformance is high, and the characteristic of resisting torque is achieved.

Owner:CENT SOUTH UNIV

Rapid extrusion aluminum alloy section with low rare earth content and preparation process thereof

The invention discloses a rapid extrusion aluminum alloy profile with low rare earth content and a preparation process thereof, and belongs to the technical field of metal materials. The aluminum alloy comprises the following components in percentage by weight: 0.8 to 1.2 percent of Mg, 0.7 to 1.2 percent of Si, 0.5 to 0.6 percent of Cu, 0.2 to 0.8 percent of Sc, 0.2 to 0.5 percent of Zr and the balance of aluminum. A trace or a small amount of rare earth element (Sc) is added into the aluminum alloy, so that the alloy cost is effectively reduced. The extrusion speed is higher than 5m / min, the extrusion production efficiency is high, the cost of the extrusion material is reduced, the surface of the obtained extrusion material is smooth and free of surface cracks, and the yield of the extrusion material is guaranteed; meanwhile, the obtained extruded material also possibly has a weak basal texture or a weak non-basal texture; and the room-temperature elongation of the extruded material can be greater than or equal to 8% through optimized components. Therefore, the method has good application and popularization prospects and can be applied to the low-cost civil fields such as electric buses and rail transit.

Owner:SHANDONG NANSHAN ALUMINUM

Semi-solid magnesium alloy gradient extrusion combination die

The invention provides a semi-solid magnesium alloy gradient extrusion combination die. The left side of a supporting plate of the die is fixedly connected with a casting-rolling machine rack througha bolt, the right side of the supporting plate of the die is connected with a temperature control room through a bolt, and the interior of the die is connected with a diversion room, a male die and afemale die in an interference fit manner. The supporting plate is connected with the diversion room through a bolt, the right side of the diversion room is connected with the male die and the female die in a clearance fit manner, and the right end of the temperature control room is connected with a support through a bolt. The support is connected with the female die through a bolt, the left end ofa core bar is fixed to the male die, and the axis of the core bar coincides with the axis of the female die. In other words, a core is in interference fit with a core hole, a solution enters a diversion hole through a diversion bridge in a diversion manner, then enters a welding room and finally flows out of the core hole, backward spiral type cooling liquid is distributed on the periphery of themale die and the periphery of the female die, and therefore the solution solid phase rate is controlled. By means of the semi-solid magnesium alloy gradient extrusion combination die, the texture distribution is effectively improved, the anisotropy is weakened, the plastic forming capability of products is improved, and energy is saved; and the beneficial effects that the production capacity is high, the quality is high, flexibility is high, and production is stable are achieved.

Owner:TAIYUAN UNIVERSITY OF SCIENCE AND TECHNOLOGY

A low-cost high-speed extrusion magnesium alloy material and its preparation process

The invention discloses a low-cost high-speed-extruded magnesium alloy material and a preparation process thereof and belongs to the technical field of metal materials. The extruded material comprises the following chemical components by weight percent: 0.1-0.9% of Zn, 0.1-0.5% of Ca, 0-0.5% of Mn and the balance Mg and inevitable impurities, wherein the total content of the alloy elements (Zn, Ca and Mn) does not exceed 1.5 wt%. Production is performed at the extrusion outlet speed of more than or equal to 24 m / min, the extrusion production efficiency is high, the cost of the extruded material is lowered, the extruded material is smooth in surface and has no surface cracks, and therefore, the yield of the extruded material is guaranteed; and meanwhile, the extruded material has a weak non-basal texture with the maximum density value of less than or equal to 4. The extruded material is low in content of alloy elements, does not contain rare earth elements or other noble metal elements, and therefore, is low in cost.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

A Homogenization Heat Treatment Process for Reducing Anisotropy of Wide Rolled Aluminum Sheet

The invention discloses a homogenization heat treatment process for reducing the anisotropy of wide-width rolled aluminum plates, adding 0.1-0.5 wt% of rare earth element Er to 5052 alloy; and then performing two-stage or three-stage homogenization heat treatment; The two-stage homogenization heat treatment is performed at 530-560°C for 20-30 hours of homogenization and heat preservation, then cooled to 150-300°C for 8-12 hours, and then air-cooled to room temperature; 530-560°C for 20-30 hours of homogenization and heat preservation, then cooled to 150-180°C and heat preservation for 8-12 hours, further raised to 300-320°C and continued heat preservation for 8-12 hours, and then air-cooled to room temperature. The method can effectively control the solid solution and precipitation of the second phase, effectively spheroidize the undissolved non-equilibrium compounds in the alloy, significantly improve the plasticity of the alloy, and reduce the anisotropy of the structure and deformation of the rolled plate.

Owner:CHONGQING UNIV

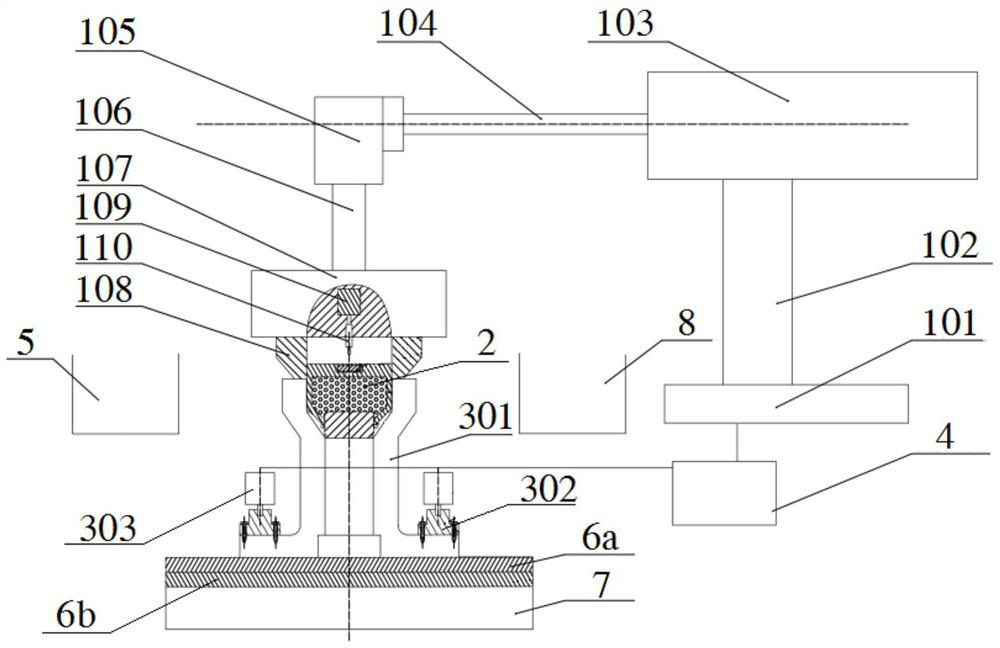

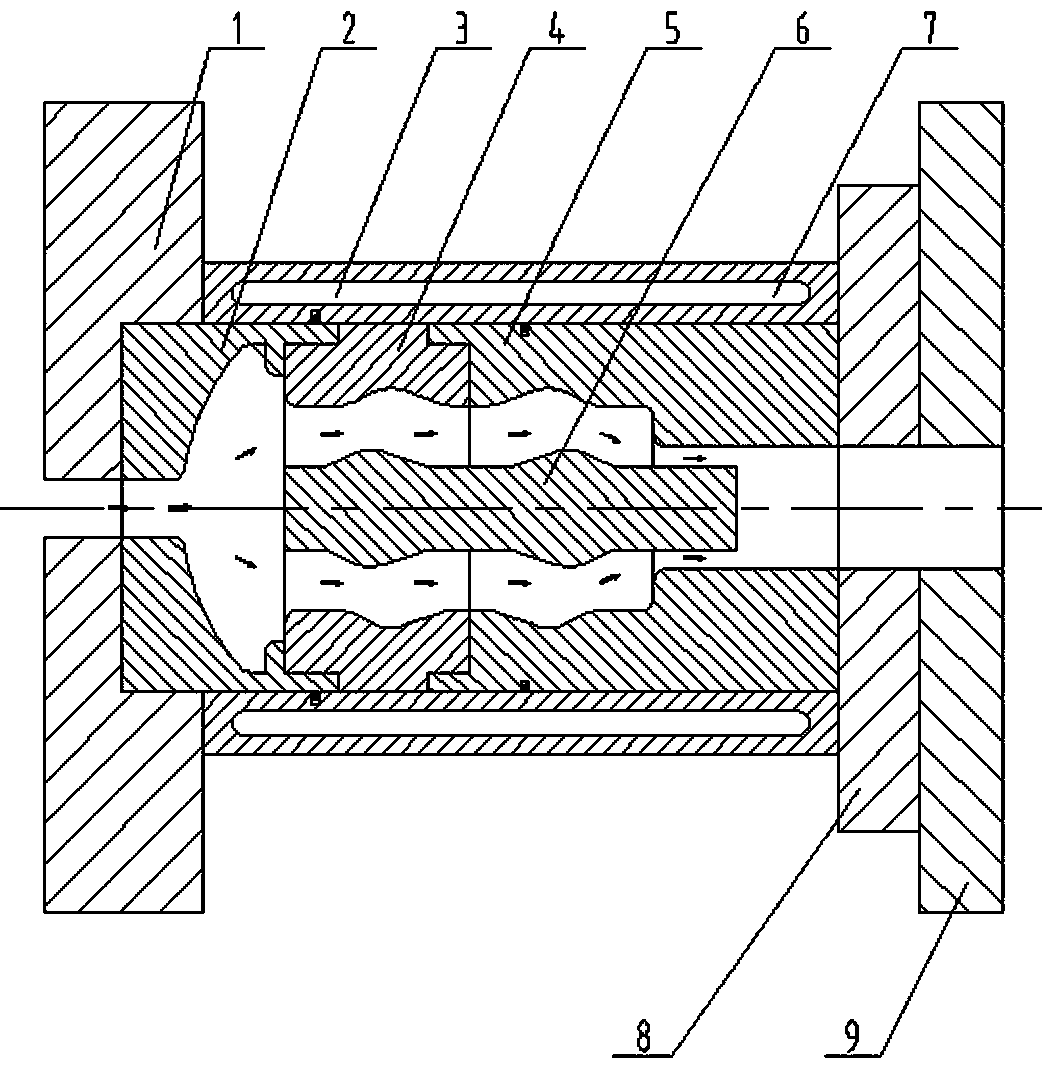

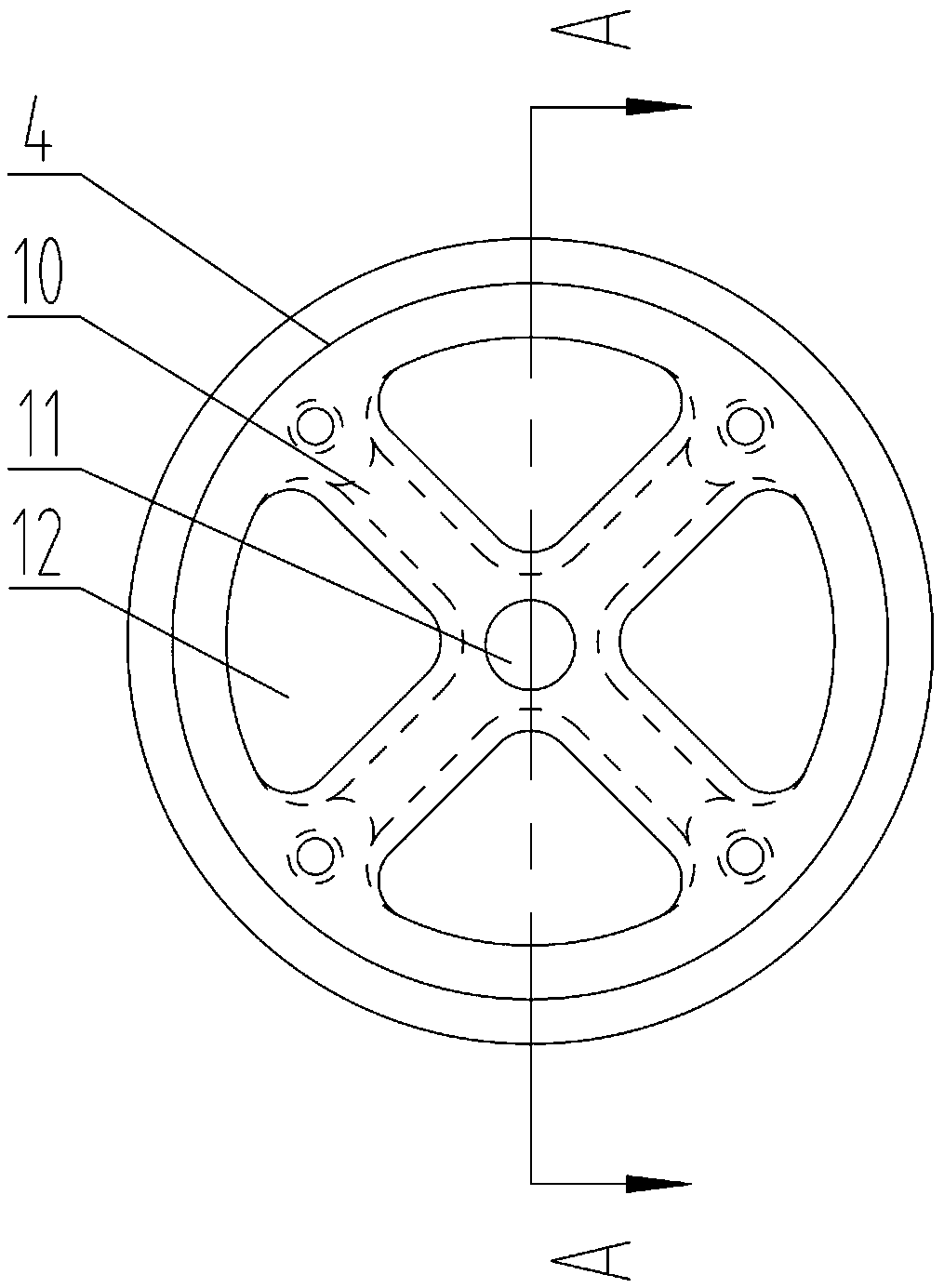

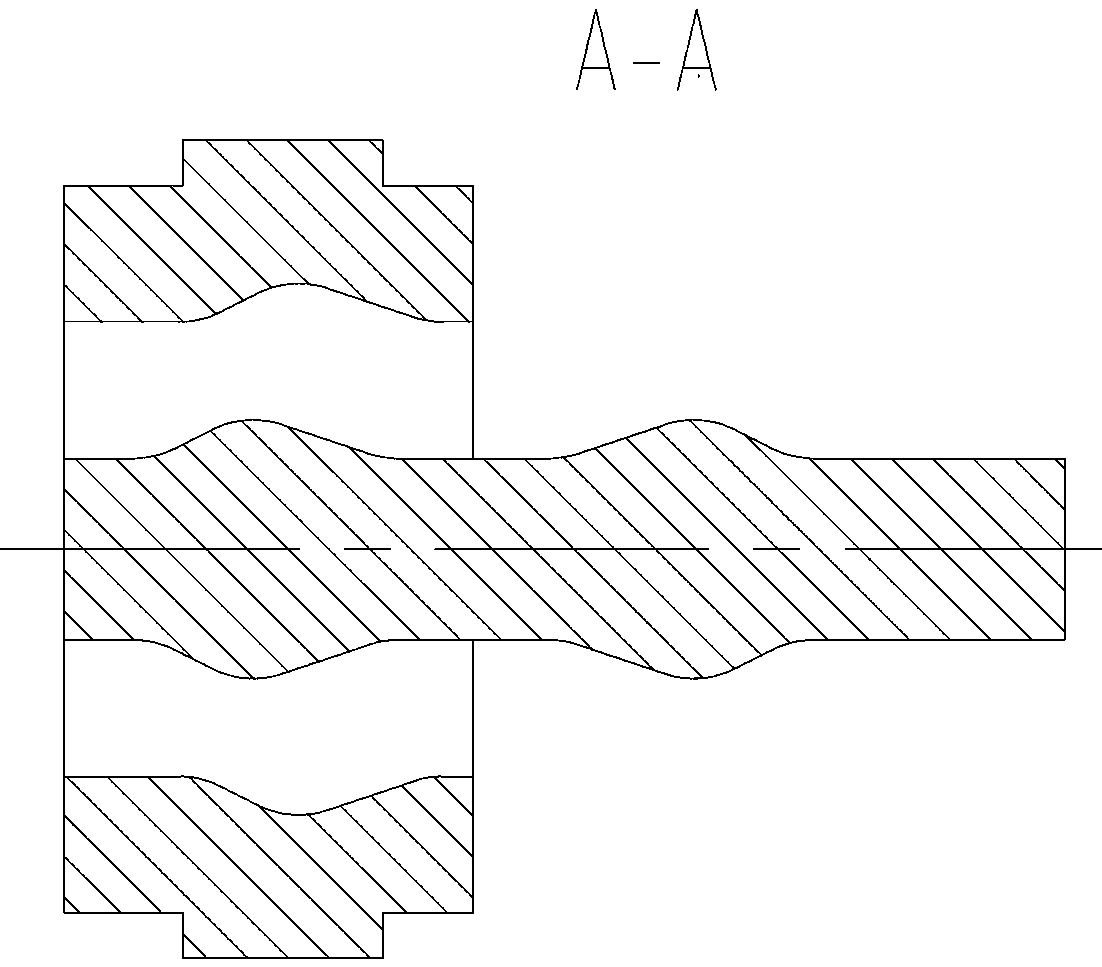

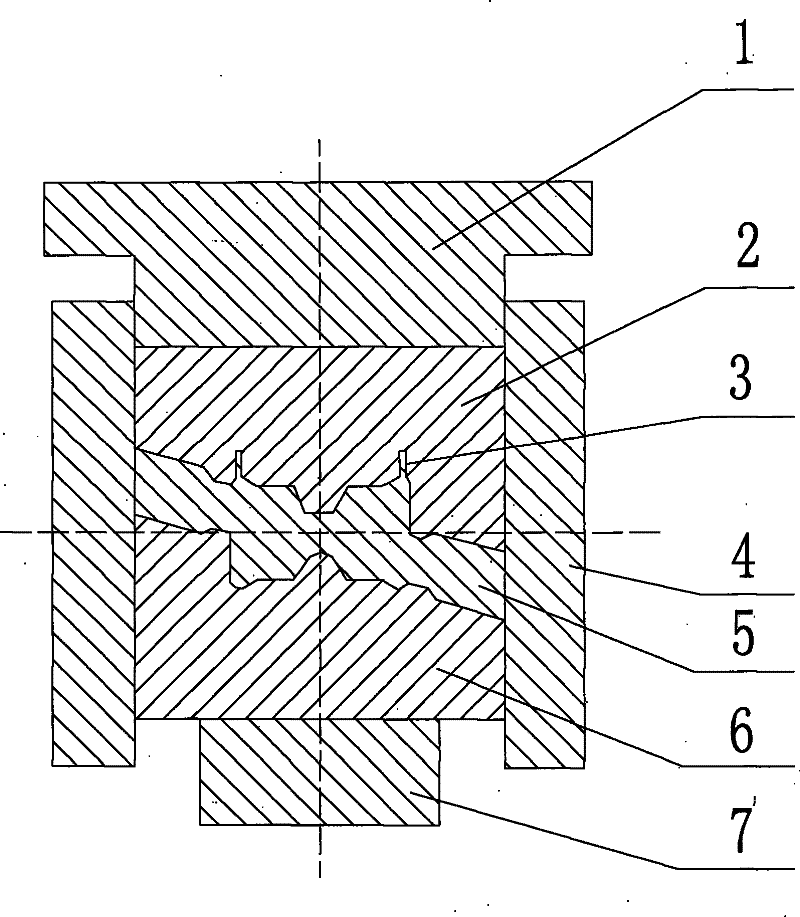

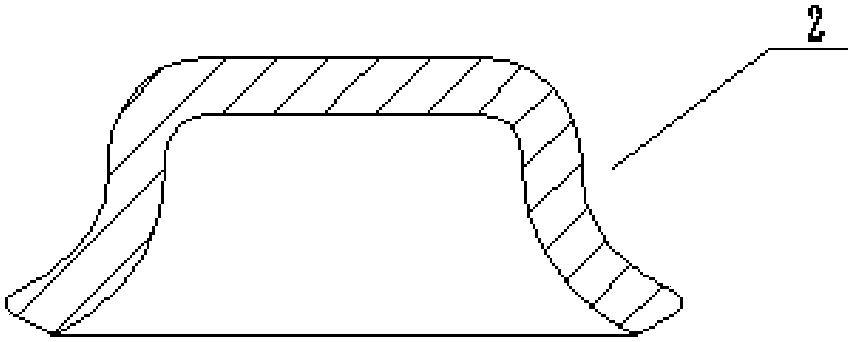

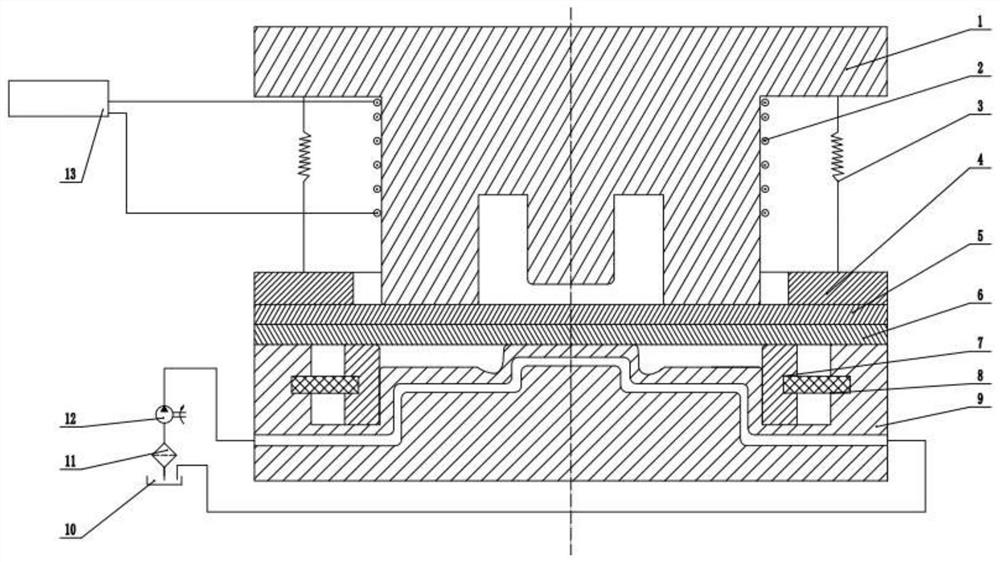

Multi-ram die forging process method and die for 40Cr-steel frame type parts

InactiveCN102049456BIncrease profitImprove plastic forming abilityForging/hammering/pressing machinesIntermediate frequencyMetallic materials

The invention discloses a multi-ram die forging process and a die for 40Cr-steel frame type parts, belongs to the technical field of plastic forming for a metal material, and aims at effectively avoiding the problems in an existing open die forging process and a existing isothermal forging process. The multi-ram die forging process comprises the steps of blanking, heating and multi-ram die forging, wherein, the multi-ram die forging comprises the steps as follows: (1) stocks are heated until the temperature reaches 1000 to 1180 DEG C through intermediate frequency induction; and (2) heated blanks are formed in one step through a multi-ram die forging die. The multi-ram die forging die comprises symmetrical left and right lateral male dies, an upper half male die, a lower half male die, a lateral male die fixing board and a die frame, wherein, the die frame comprises an upper die holder and a lower die holder. The invention has the advantages as follows: the technological process is reasonable, and the processing parameter and the performance are stable; the structure of the die is simple, the die is convenient to manufacture, install and use, and the operation is reliable; the friction resistance between forged pieces and a die cavity can be reduced greatly, the service life of the die is prolonged obviously, the surface quality of the forged pieces can be improved, and the utilization ratio of materials is high; and one-step forming can be achieved, and pre-forging is not required.

Owner:CHONGQING UNIV OF TECH

A kind of magnesium alloy with high plastic deformation at room temperature and preparation method thereof

ActiveCN103866169BMeet the needs of plastic processingIncrease productivitySmelting processRoom temperature

The invention provides room-temperature high-plasticity wrought magnesium alloy and a preparation method thereof. The magnesium alloy comprises the following components by weight percent: 5.5wt%-7.3wt% of Al, 0.40wt%-1.50wt% of Zn, 0.15wt%-0.50wt% of Mn, 0.05wt%-1.0wt% of P and the balance being Mg and inevitable impurities, wherein the inevitable impurities comprise the following components: not more than 0.05wt% of Si, not more than 0.004wt% of Fe, not more than 0.004wt% of Cu and not more than 0.002wt% of Ni. According to the magnesium alloy, a nonmetal element P is added in an existing magnesium alloy smelting process, a stable small grain structure is obtained under the action of the nonmetal element P, the room-temperature plasticity is improved, and the room-temperature processing and using requirements of finished products or semi-finished products can be met.

Owner:SUZHOU KAI YOU ELECTRONICS SCI & TECH LTD

Preparation process of modified magnesium borate crystal whisker reinforced magnesium-matrix composite material

InactiveCN101705458BImprove interface binding stateImprove plastic forming abilityMagnesium matrix compositeVacuum pressure

The invention belongs to the technical field of new materials, in particular to a preparation process for modifying and optimizing magnesium alloy matrix and reinforcing the interphase contact surface and interface aiming at the magnesium borate crystal whisker reinforced magnesium-matrix composite material. The study proves that no obvious interface reaction occurs at the interface of the magnesium borate crystal whisker and the magnesium matrix, and the bonding strength of the interface is not high. By adopting the invention, the interface of the crystal whisker reinforced magnesium-matrix composite material reaches a better bonding state, and the performance of the magnesium borate crystal whisker reinforced magnesium-matrix composite material is improved. The preparation process comprises steps of coating the magnesium borate crystal whisker, preparing the modified magnesium borate crystal whisker prefabricated block, preparing cast composite ingot blank by a vacuum pressure infiltration method; and thermally extruding the ingot blank. The composite material comprises components of aluminium isopropoxide Al(OC3H7)3, distilled water, muriatic acid, magnesium borate crystal whisker, magnesium and the balance of magnesium alloy.

Owner:QINGHAI UNIVERSITY

Die Forging Process and Die of High Silicon Aluminum Alloy Swash Plate

InactiveCN101628312BIncrease profitSmall particlesForging/hammering/pressing machinesWheelsSiliconHeating temperature

High-silicon aluminum alloy swash plate die forging process, the plastic forming of the die forging is realized by the small flash open forging die. The heating temperature is 500°C±5°C, the die preheating temperature is 200°C±5°C, and the small flash die forging process directly die-forges the heated aluminum alloy bar into a swash plate die forging with small flash. The die is an open forging die with small flash, which is composed of an upper punch, a lower punch and an extrusion cylinder. The die adopts a separable structure. 3mm, thickness of 0.5mm ring-shaped uniform gap, that is, the flash groove, the draft angle of all surfaces in contact with the extrusion cylinder is less than or equal to 5 degrees, the process flow of the invention is reasonable, the process parameters and performance are stable, the mold structure is simple, It is easy to manufacture, install and use, and works reliably.

Owner:冯福贵 +2

A composite die for gradient extrusion of semi-solid magnesium alloy

The invention provides a semi-solid magnesium alloy gradient extrusion combination die, the left side of the supporting plate is connected and fixed with the frame of the casting and rolling mill through bolts, the right side is connected with a shunt chamber through interference fit, and the right side of the shunt chamber is connected with the punch through a clearance fit , the right side of the punch is connected to the die through clearance fit, the right side of the die is connected to the support by bolts, and the right side of the support is connected to the base; a control room is set between the support and the support plate, and the control room is wrapped in a ring shape in the shunt chamber, die and punch outside; the left end of the mandrel is fixed on the punch, and its axis coincides with the axis of the die; that is, the solution flows through the shunt bridge into the shunt hole, then enters the welding chamber, and finally passes through the core hole Outflow, post-advance spiral coolant is distributed around the punch and die, so as to control the solid phase ratio of the solution. The invention effectively improves texture distribution, weakens anisotropy, improves the plastic forming ability of products, and saves energy; it has the advantages and positive effects of high production capacity, good quality, strong flexibility and stable production.

Owner:TAIYUAN UNIVERSITY OF SCIENCE AND TECHNOLOGY

Two-way hydroforming mold for microtubes

The invention discloses a two-way hydroforming mold for microtubes, which includes a guide block, a cylindrical shell, an insert, a blank holder and a sealing block; the invention can simultaneously apply pressure to the inner and outer surfaces of the microtube, and drive the microtube through the pressure difference. Tube forming; the introduction of back pressure can prevent the generation, growth and nucleation of micro-cracks inside the micro-tube, and then greatly improve the plastic forming ability of the micro-tube; and the present invention installs an O-shaped Sealing ring, the sealing performance is greatly improved, and it can seal the high-pressure liquid with a pressure of up to 350MPa; at the same time, it also isolates the high-pressure liquid inside and outside the microtube, avoiding the connection of high-pressure liquid inside and outside; An O-ring is installed to prevent the external high-pressure liquid from communicating with the internal pressure through the insert.

Owner:NANJING UNIV OF SCI & TECH

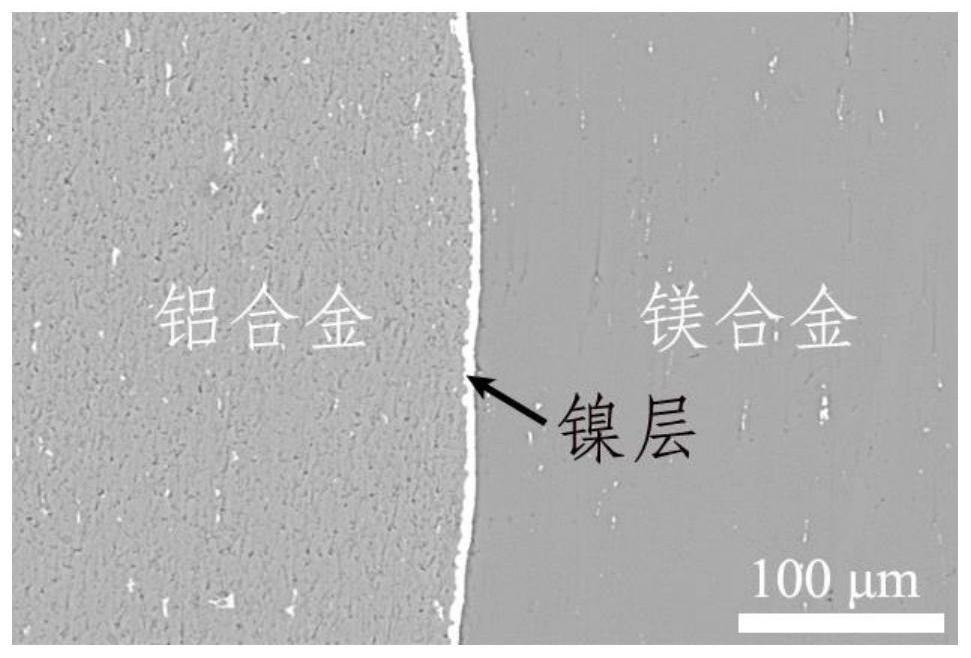

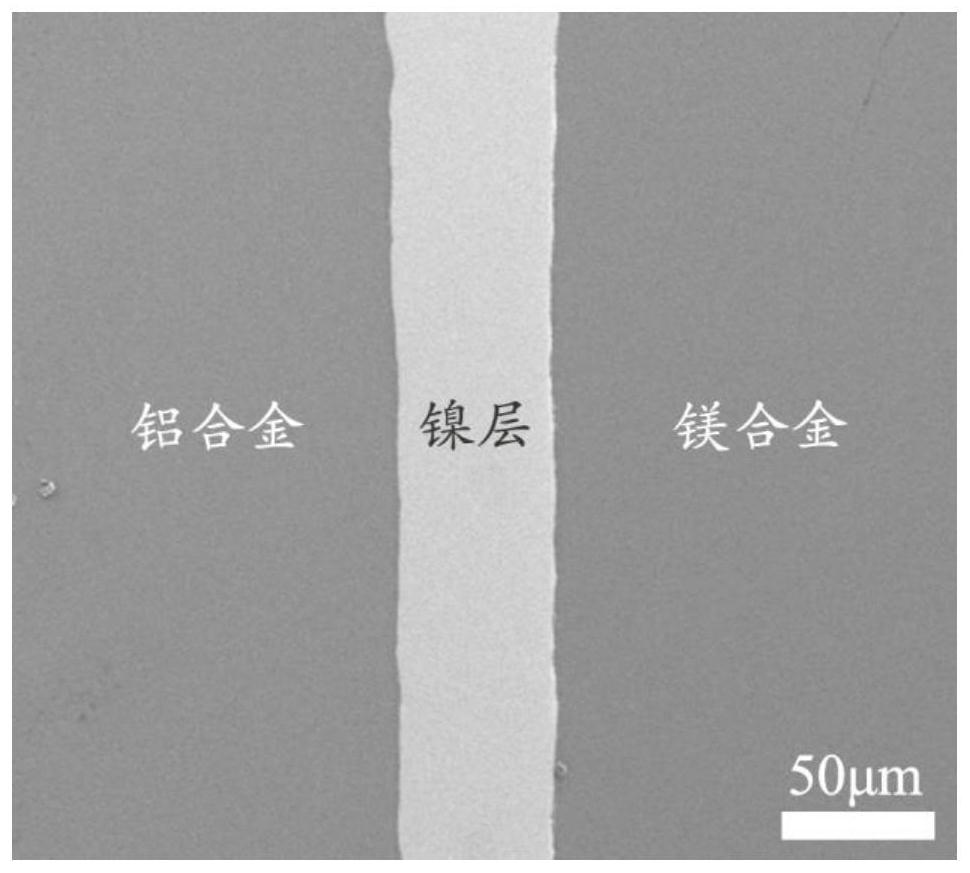

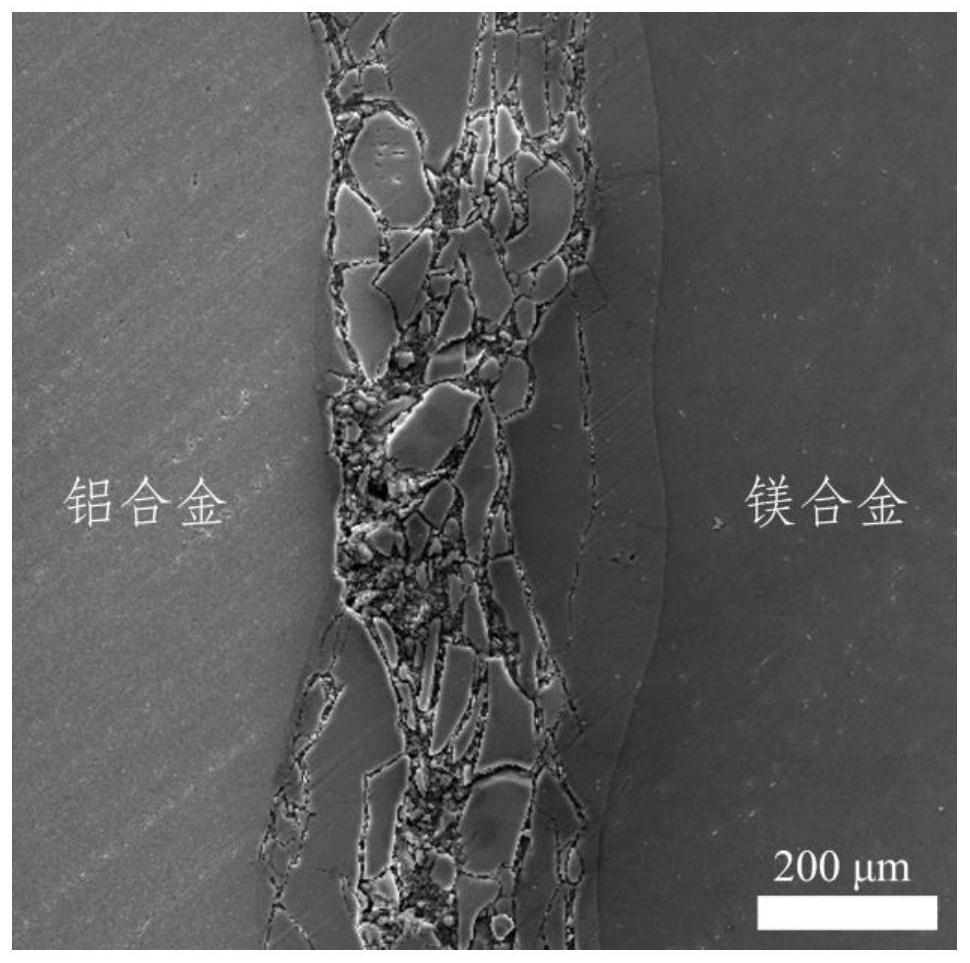

Magnesium-aluminum layered composite board and preparation method thereof

PendingCN114558903ARefine the grain sizeHigh strengthRolling mill drivesAuxillary arrangementsComposite plateAluminum composites

The invention relates to the field of layered composite materials, in particular to a magnesium-aluminum layered composite plate and a preparation method thereof. The preparation method of the magnesium-aluminum layered composite plate comprises the following steps: preparing a composite pipe blank by adopting centrifugal casting; the composite pipe blank is pretreated to form a composite board; two or more composite boards with the same size are stacked and rolled according to the mode that aluminum layers and magnesium layers are alternately arranged at intervals, the magnesium-aluminum layered composite board is obtained, and a nickel layer is arranged between every two adjacent composite boards. And centrifugal casting is adopted, so that the grain size of the composite plate is refined, the strength and the plastic forming capacity are improved, and subsequent rolling deformation is facilitated. And a nickel layer is arranged between the composite plates before ply rolling, so that a large number of hard and brittle intermetallic compounds are prevented from being generated at the interface of the composite plates at the medium-high temperature (350-500 DEG C), and the mechanical property of the magnesium-aluminum composite plate is improved.

Owner:GUANGDONG INST OF NEW MATERIALS

Spiral riveting welding device and method for explosive impact forming

ActiveCN111659845BHigh strengthStable Solid State WeldingRivetsSheet joiningElectrical connectionEngineering

The invention provides a spiral riveting and locking welding device for explosive impact forming, comprising: an implementing mechanism, a rivet unit, a guiding and blanking mechanism and a controller; the said rivet unit is collectively stored in a rivet box, and the said implementing mechanism can be moved , the implementing mechanism is used to take the rivet unit from the rivet box and place it on the guide crimping mechanism and fire the rivet unit, and the guide crimping mechanism is pre-pressed on the upper plate and the lower plate On the above, the guide edge clamping mechanism is used to press the upper plate and the lower plate on the flat die, and the controller is electrically connected to the implementing mechanism and the guide edge clamping mechanism respectively, and the controller is used to control the The movement of the implementing mechanism and the pressing of the guiding edge-holding mechanism; also provide a spiral riveting welding method for explosive impact forming. The invention has reasonable structural design, high degree of operation automation, can efficiently complete plate connection, has high connection point precision, strong mechanical performance, and has the characteristics of torque resistance.

Owner:CENT SOUTH UNIV

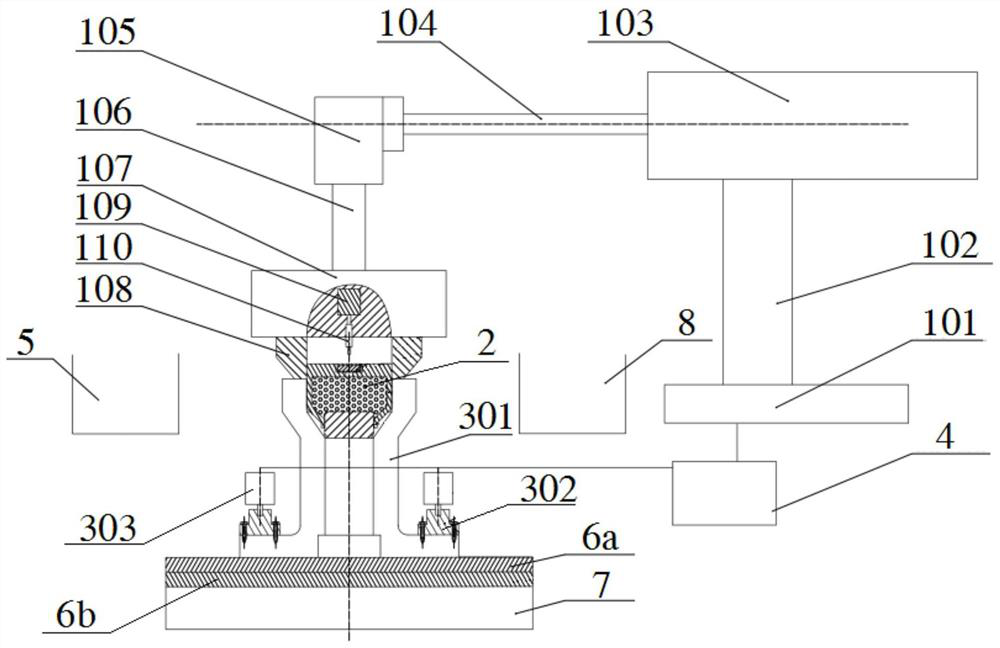

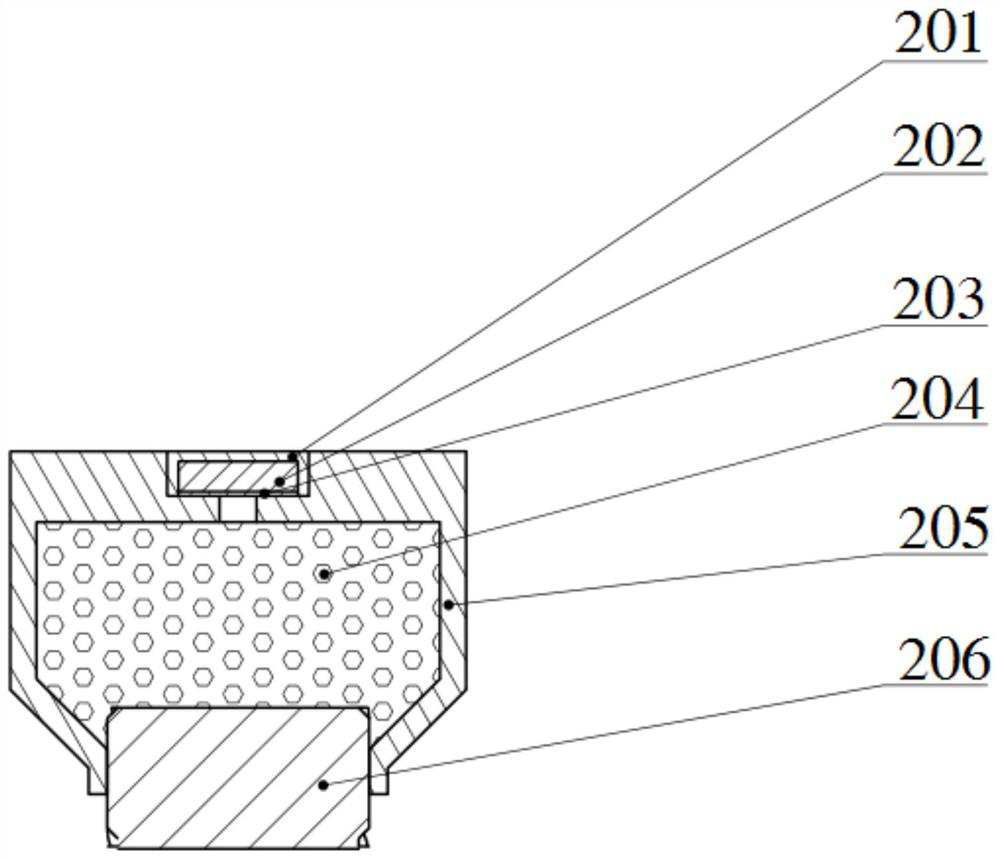

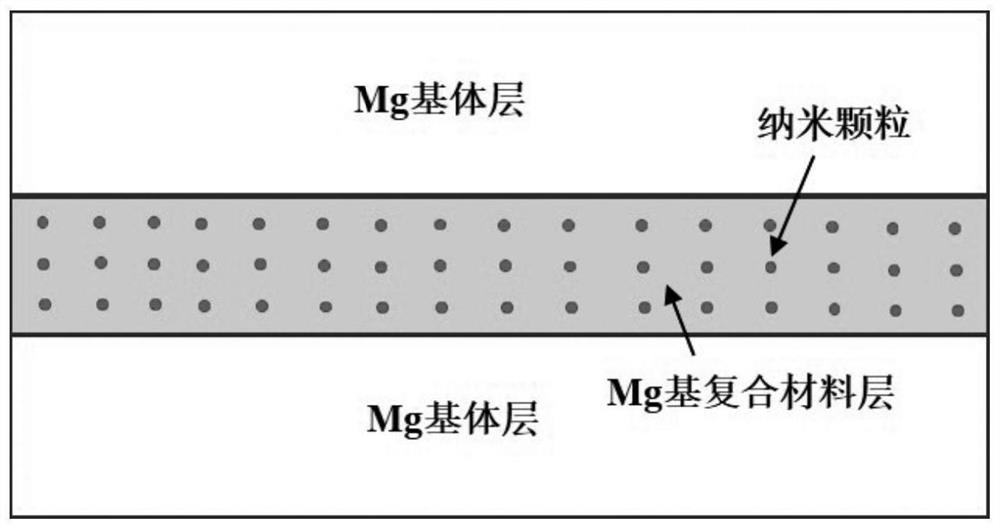

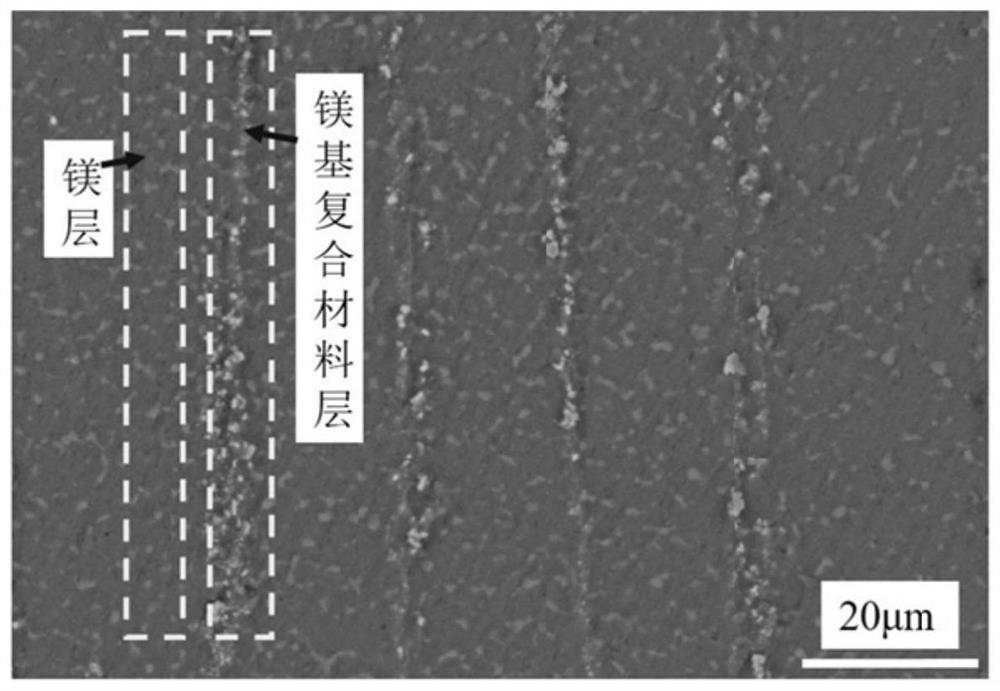

Layered magnesium-magnesium-based composite material plate as well as preparation method and application thereof

ActiveCN114134302AImprove performanceSolve the strength problemMetal rolling arrangementsMg compositeMagnesium matrix composite

The preparation method comprises the following steps: synthesizing an Al-TiB2 intermediate alloy containing nanoscale TiB2 ceramic particles through an in-situ reaction, adding the Al-TiB2 intermediate alloy into a magnesium alloy melt to obtain a TiB2 / Mg composite material, carrying out hot rolling to obtain a thin plate, alternately stacking the thin plate and a pure magnesium plate, and carrying out vacuum hot pressing sintering to obtain the layered magnesium-magnesium-based composite material plate. And the layered magnesium / magnesium-based composite material plate with excellent performance can be prepared through multi-pass hot rolling. In the macroscale, the ceramic particles are non-uniformly distributed in a layered manner, and in the microscale, the ceramic particles are uniformly distributed in the magnesium-based composite material layer. The strength, plasticity and toughness of the laminated composite material plate can be flexibly and accurately regulated and controlled by regulating and controlling the content of TiB2 particles in the laminated composite material and the interlayer spacing, the problem that the toughness of the composite material is mismatched is hopefully solved, and the method has a wide application prospect.

Owner:XI AN JIAOTONG UNIV

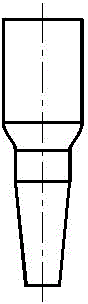

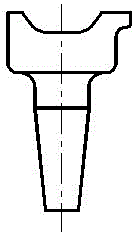

A forming process of tensioner

The invention discloses an expansion wheel forming process, and belongs to the field of machining of metal materials. The expansion wheel forming process comprises blanking-deep drawing-hot extrusion-cold extrusion-finishing-punching. Compared with the prior art, the expansion wheel forming process has the following advantages: the expansion wheel forming process overcomes such defects as weak forming quality, low production efficiency and high material waste in the prior art, forms expansion wheels by the punching and hot extrusion processes, effectively improves the part forming quality, reduces the material waste to a greater extent, improves the production environment, can realize automatic production by applying the punching and hot extrusion processes, improves the production efficiency, reduces the production cost, and satisfies a lot of market demands.

Owner:HEFEI UNIV OF TECH +1

A hot stamping forming triple lock type connecting device and method

ActiveCN111659806BReduce quality problemsImprove corrosion resistanceShaping toolsHot stampingPunching

Owner:CENT SOUTH UNIV

Precision die forging and shaping technical method for automobile steering knuckle rough type parts

InactiveCN102672096BLow forming speedNo crack phenomenonRailway componentsMetal-working apparatusIntermediate frequencyRound bar

The invention provides a precision die forging forming process for automobile steering knuckle blank parts, which mainly includes blanking, heating, extrusion and elongation of the rod, pre-forging and upsetting, multi-directional precision die forging forming processes; The material is heated to 1080°C to 1180°C in an intermediate frequency induction furnace; the heated round bar is put into the die of the extrusion elongation die to form a blank composed of a cylindrical surface and a steering knuckle blank rod; the upsetting The raw material after rough splitting is put into the multi-directional die forging die, the upper punch and the upper die seat in the vertical direction go down first, and the upper punch and the lower die are forged together; the symmetrical left and right punches in the horizontal direction Then extrusion precision forging molding. In the method of the present invention, since the die forging is performed on a multi-directional die forging hydraulic press, its forming speed is much lower than that of the hammer die forging, and there is no phenomenon that cracks occur on the surface due to high speed sensitivity due to excessive speed; It can greatly reduce the contact friction resistance between the forging and the surface of the die cavity in the process of die forging forming and forging ejection, further improve the surface quality of forgings, and improve the utilization rate of forging materials.

Owner:CHONGQING UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com