Spiral rivet lock welding device and method for explosive shock forming

An explosive impact and spiral technology, which is applied in the direction of rivets, connecting members, and thin plate connections, can solve the problems of low dimensional accuracy of connection points, easy to produce circumferential rotation, easy to damage plates, etc., achieve fast speed, improve mechanical properties, The effect of high connection dimensional accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] In order to make the technical problems, technical solutions and advantages to be solved by the present invention clearer, the following will describe in detail with reference to the drawings and specific embodiments.

[0039] The invention provides a spiral riveting and locking welding device and method for explosive impact forming, aiming at the problems of easily damaged plates, high sensitivity, low dimensional accuracy of connection points and easy occurrence of circumferential rotation in existing self-piercing riveting.

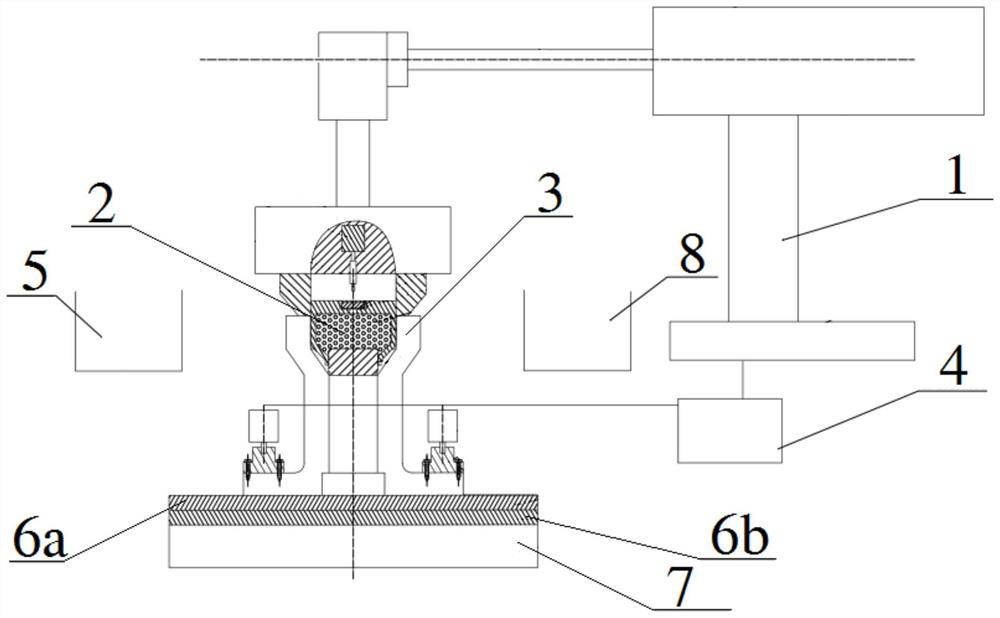

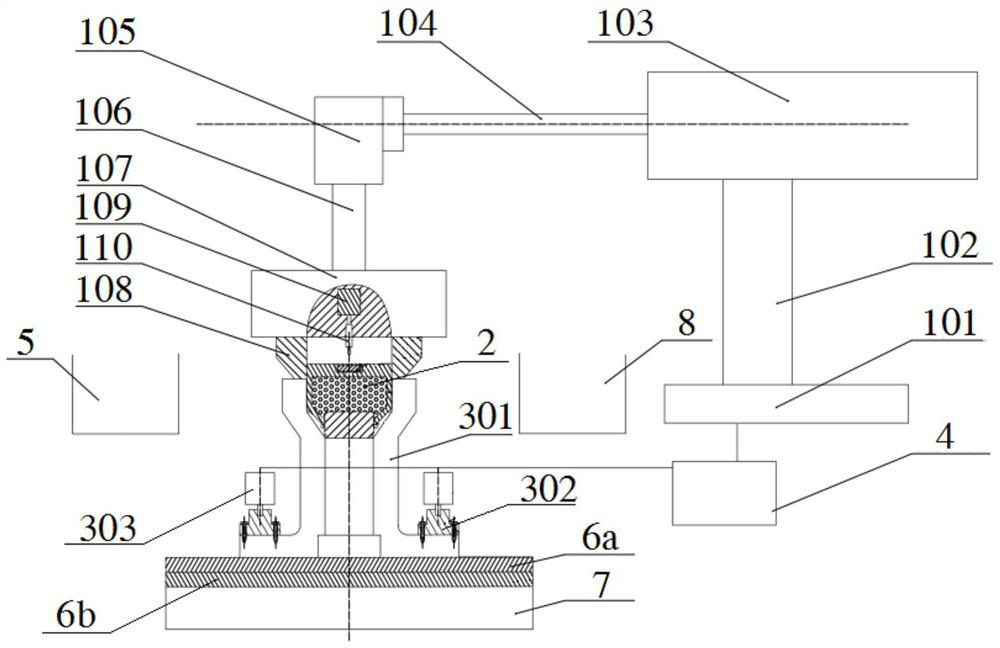

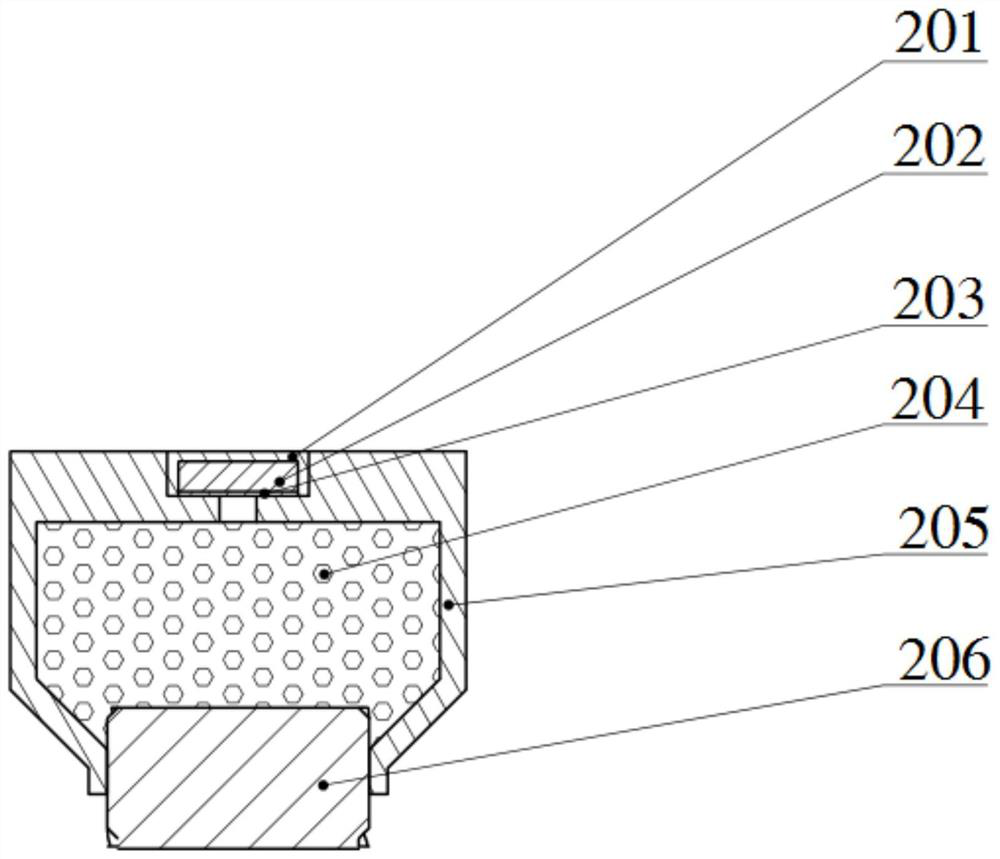

[0040] Such as figure 1 As shown, the embodiment of the present invention provides a screw rivet lock welding device for explosive impact forming, including: an implementing mechanism 1, a rivet unit 2, a guide blank holder mechanism 3 and a controller 4; the rivet unit 2 is stored in a centralized In a rivet box 5, the implementation mechanism 1 is movable, and the implementation mechanism 1 is used to take the rivet unit 2 from the rivet box 5 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com