Silumin piston contour forging technique and mold

A high-silicon aluminum alloy and piston technology, applied in pistons, manufacturing tools, metal processing equipment, etc., can solve the problems of high-silicon aluminum alloy piston wrinkling, poor compactness and low strength of die-casting parts, and achieve easy manufacturing, installation and use , Improving the plastic forming performance and the effect of long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

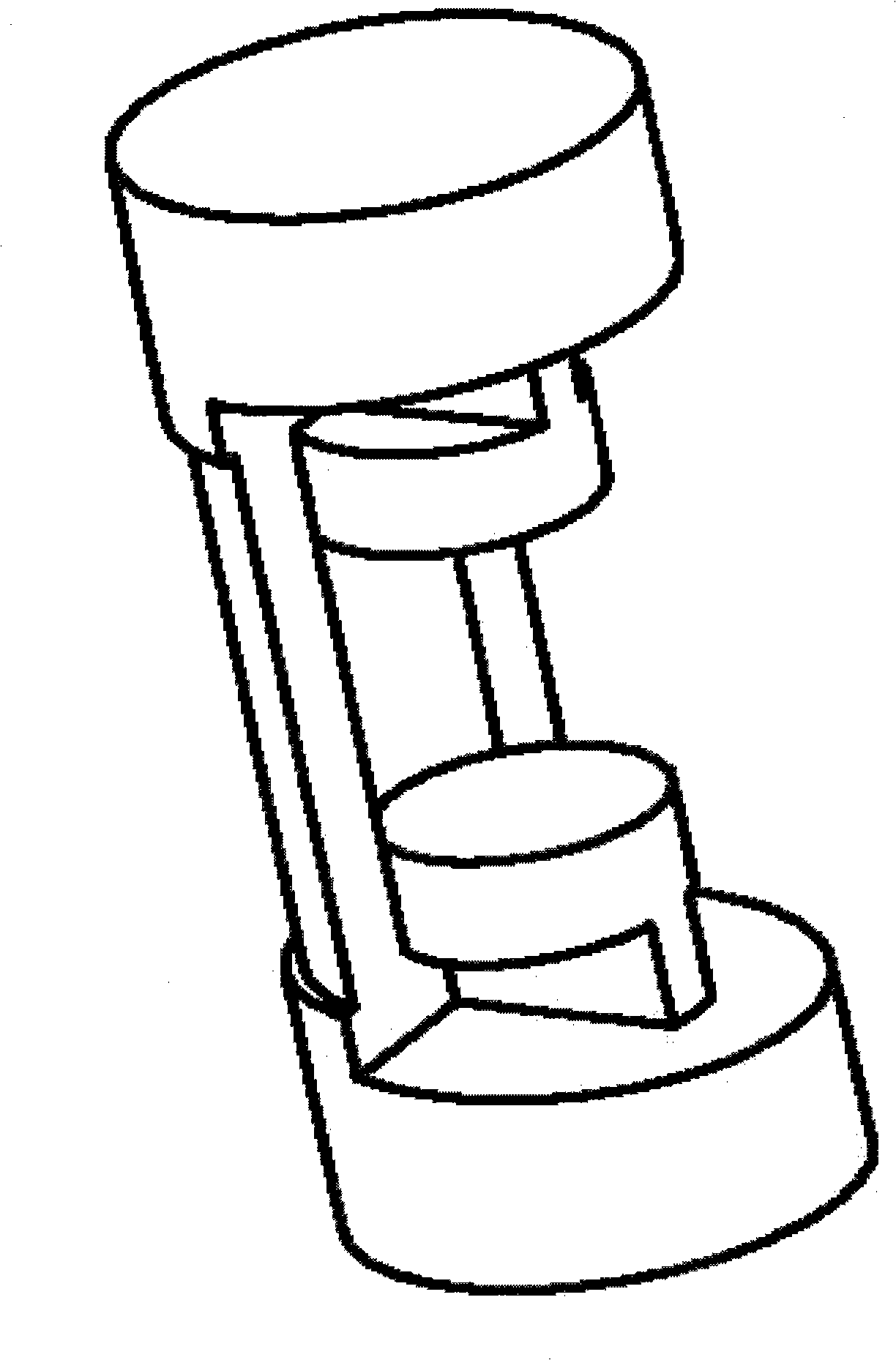

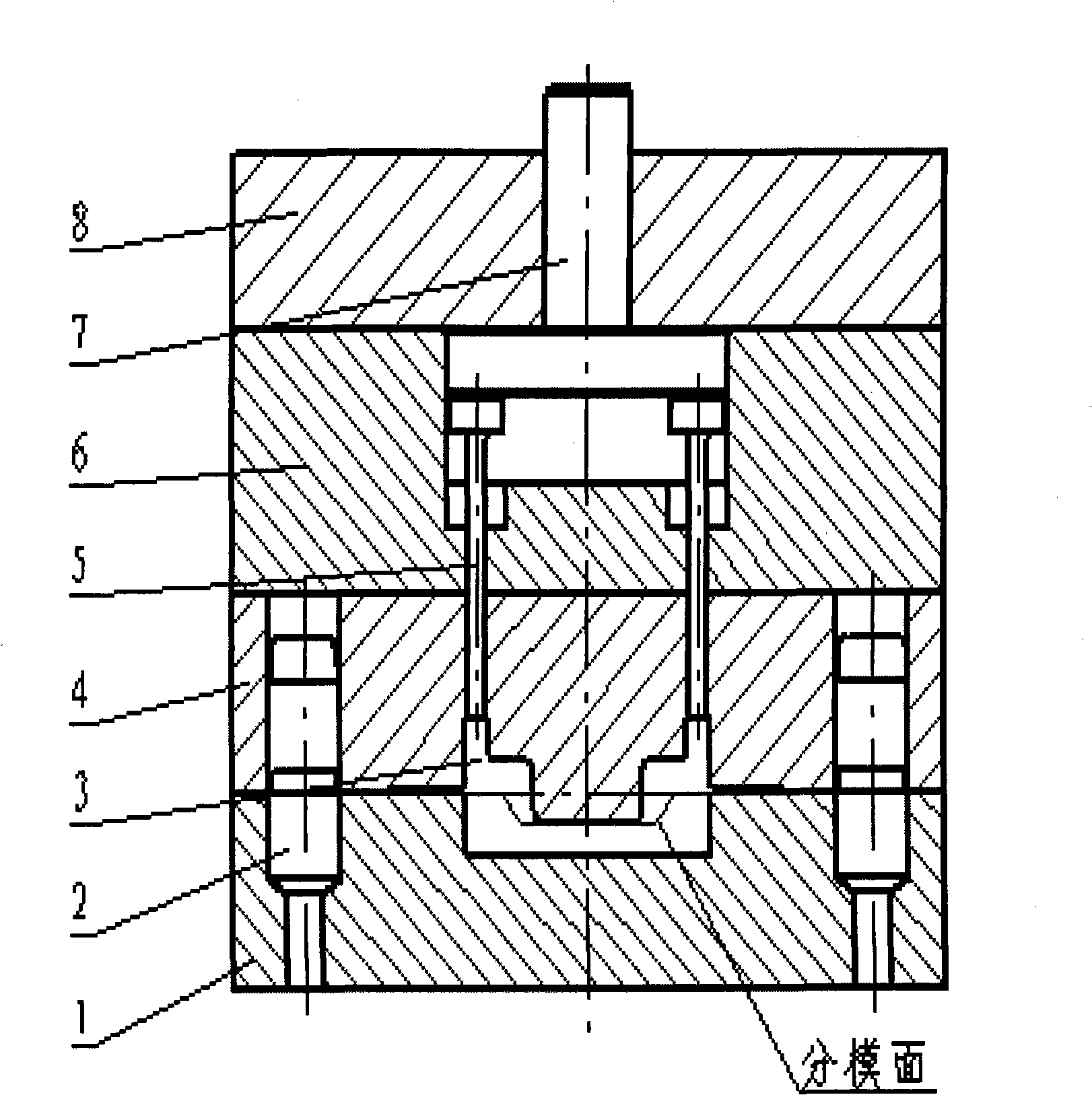

[0012] Such as figure 1 , figure 2 shown.

[0013] High-silicon aluminum alloy piston die forging die is composed of: lower die (1), guide pin (2), die cavity (forging) (3), upper die (4), ejector pin (5), die base (6 ), the ejector (7) and the slider (8) are sequentially connected, the lower die (1) is located below the upper die (4), and the lower die (1) and the upper die (4) pass through the guide pin (2) Matching the positioning, the upper mold (4) is installed under the mold base (6), the mold base (6) is located under the slide block (8), the ejector (7) is located in the middle of the slide block (8), and the slide The blocks (8) can slide relative to each other, and a push rod (5) is installed in the upper die (4) and the mold base (6), and the push rod (5) is located below the ejector (7). After forming, the ejector (7) is pushed by the slider (8), so that the formed die forging is ejected from the die cavity (forging) (3), and a mold is formed between the lower ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com