Rapid extrusion aluminum alloy section with low rare earth content and preparation process thereof

An aluminum alloy profile and preparation process technology, applied in the field of metal materials, can solve the problems of poor room temperature plasticity, low extrusion speed, high production and application costs of extruded materials, achieve high extrusion production efficiency, improve plastic forming performance, The effect of guaranteeing the yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

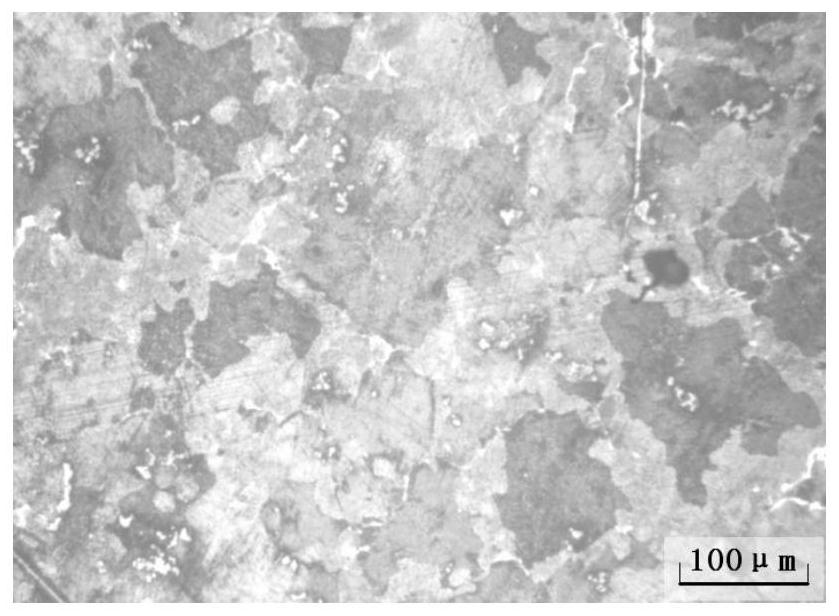

Embodiment 1

[0037] (1) Preheating pure aluminum, pure magnesium, Al-20Cu master alloy and Al-5Ti-1B master alloy at 250°C. The electric furnace was heated to 690°C, and pure Al was placed in the crucible. After the industrial pure aluminum was completely melted, the temperature was raised to 730°C and the preheated magnesium ingot, Al-20Cu master alloy, Al-20Sc master alloy and Al-20Zr were added. For the master alloy, heat it up to 760°C, add the preheated Al-5Ti-1B master alloy, and stir thoroughly during the smelting; cool the melt to 750-°C and add RJ-5 refining agent for refining, the refining time is 5 minutes, and after the refining is completed, the temperature is lowered. After standing at 710°C for 30min, cast under the condition of electromagnetic stirring with excitation voltage not higher than 120V. The semi-continuous casting Al-Mg-Si-Sc-Zr alloy is used, and the alloy composition weight percentages are: Mg 0.8wt.%, Si0.7wt.%, Cu 0.5wt.%, Sc 0.3wt.%, Zr 0.2wt.% , aluminum i...

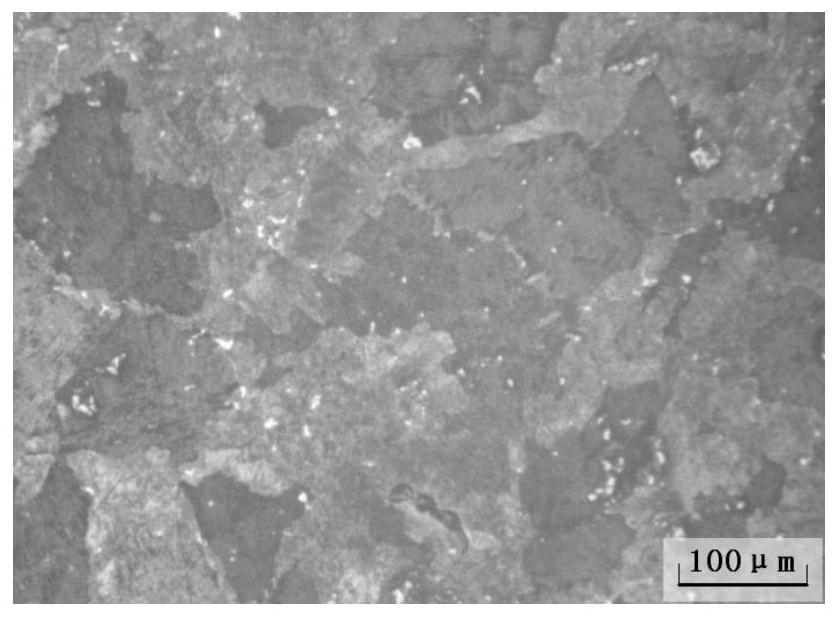

Embodiment 2

[0043] (1) Preheating pure aluminum, pure magnesium, Al-20Cu master alloy and Al-5Ti-1B master alloy at 250°C. The electric furnace was heated to 690°C, and pure Al was placed in the crucible. After the industrial pure aluminum was completely melted, the temperature was raised to 730°C and the preheated magnesium ingot, Al-20Cu master alloy, Al-20Sc master alloy and Al-20Zr were added. For the master alloy, heat it up to 760°C, add the preheated Al-5Ti-1B master alloy, and stir thoroughly during the smelting; cool the melt to 750-°C and add RJ-5 refining agent for refining, the refining time is 5 minutes, and after the refining is completed, the temperature is lowered. After standing at 710°C for 30min, cast under the condition of electromagnetic stirring with excitation voltage not higher than 120V. The semi-continuous casting Al-Mg-Si-Sc-Zr alloy is used, and the alloy composition weight percentages are: Mg 0.9wt.%, Si0.8wt.%, Cu0.5wt.%, SC0.4wt.%, Zr0.3wt.% , aluminum is t...

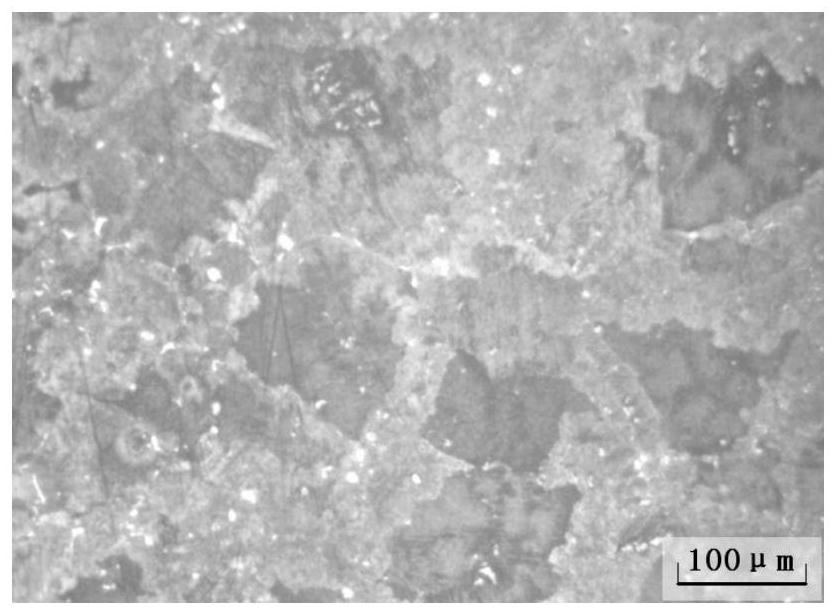

Embodiment 3

[0049] Design experiment aluminum alloy composition, casting method, blank preparation process are the same as in Example 2;

[0050] (1) Hot extrusion process: the extrusion temperature is 460°C, the extrusion ratio is 15:1, and the extrusion speed is 10m / min for forward extrusion;

[0051] (2) The profiles are aged at 180°C for 8 hours, and rapid extrusion aluminum alloy profiles with low rare earth content can be obtained;

[0052] (3) The texture of the extruded material is a weak non-basal texture, and the non-basal texture component is between the orientations of and .

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com