A composite die for gradient extrusion of semi-solid magnesium alloy

A combined mold and magnesium alloy technology, applied in the field of magnesium alloy processing, can solve problems such as prominent anisotropy, poor flexibility, and limited specifications, and achieve the effects of improving plastic forming ability, weakening anisotropy, and improving texture distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

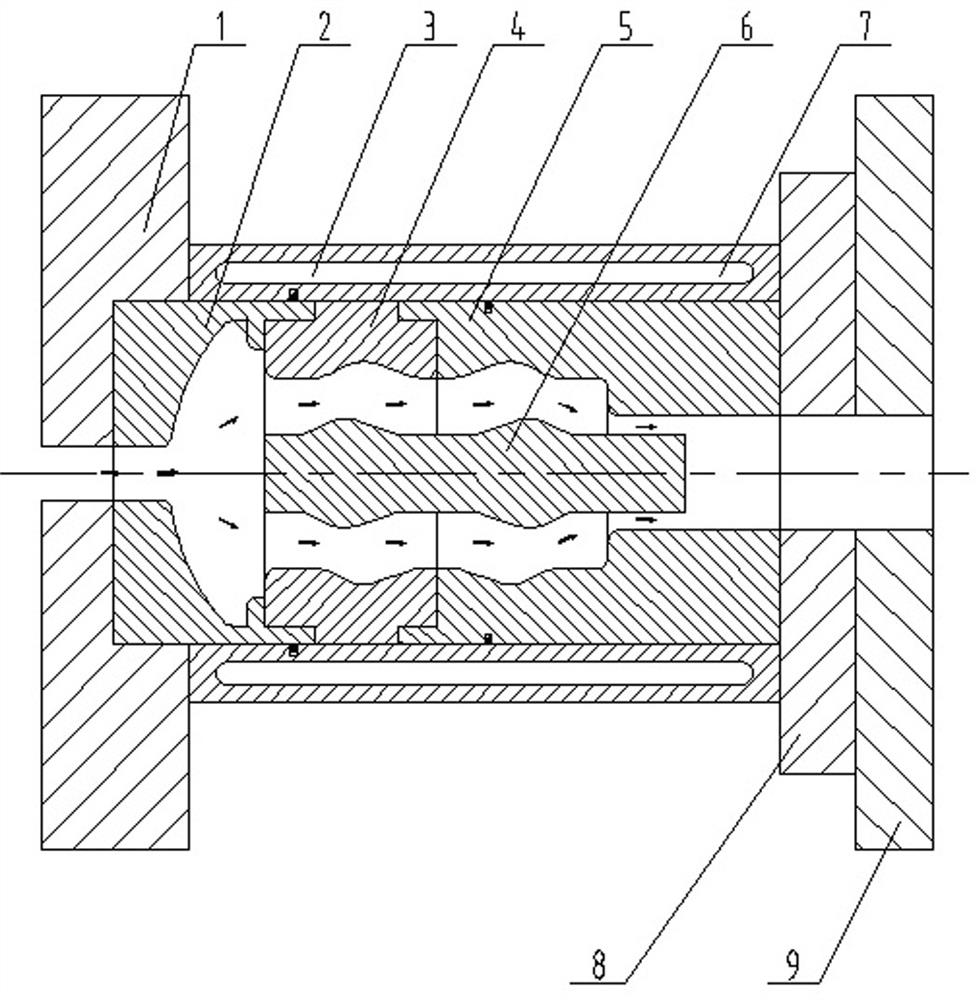

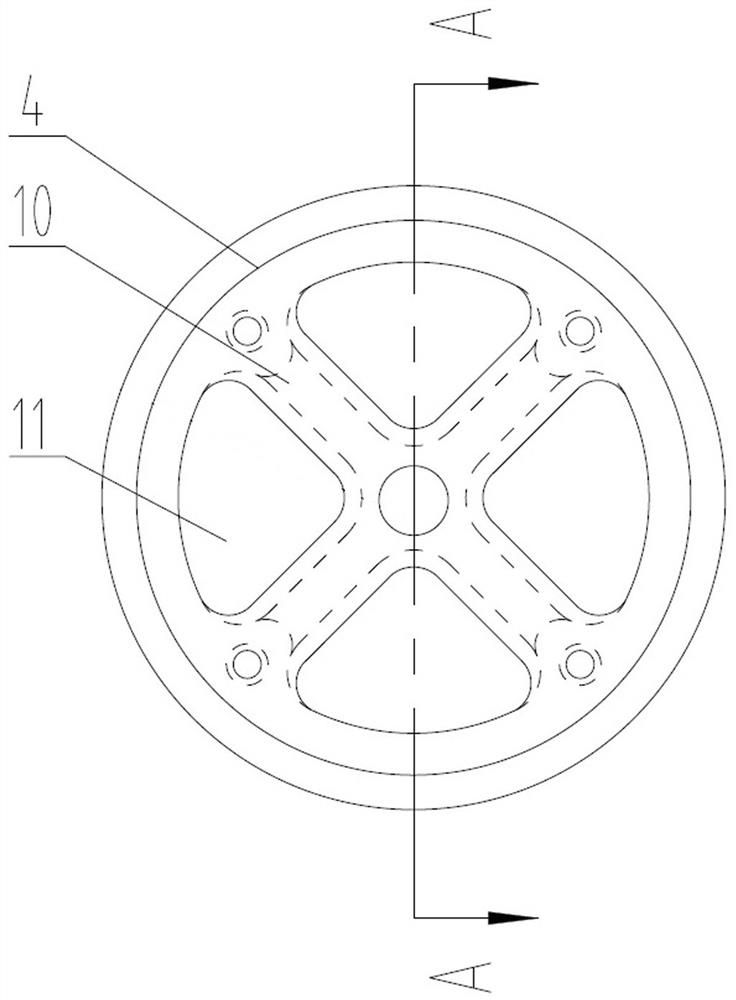

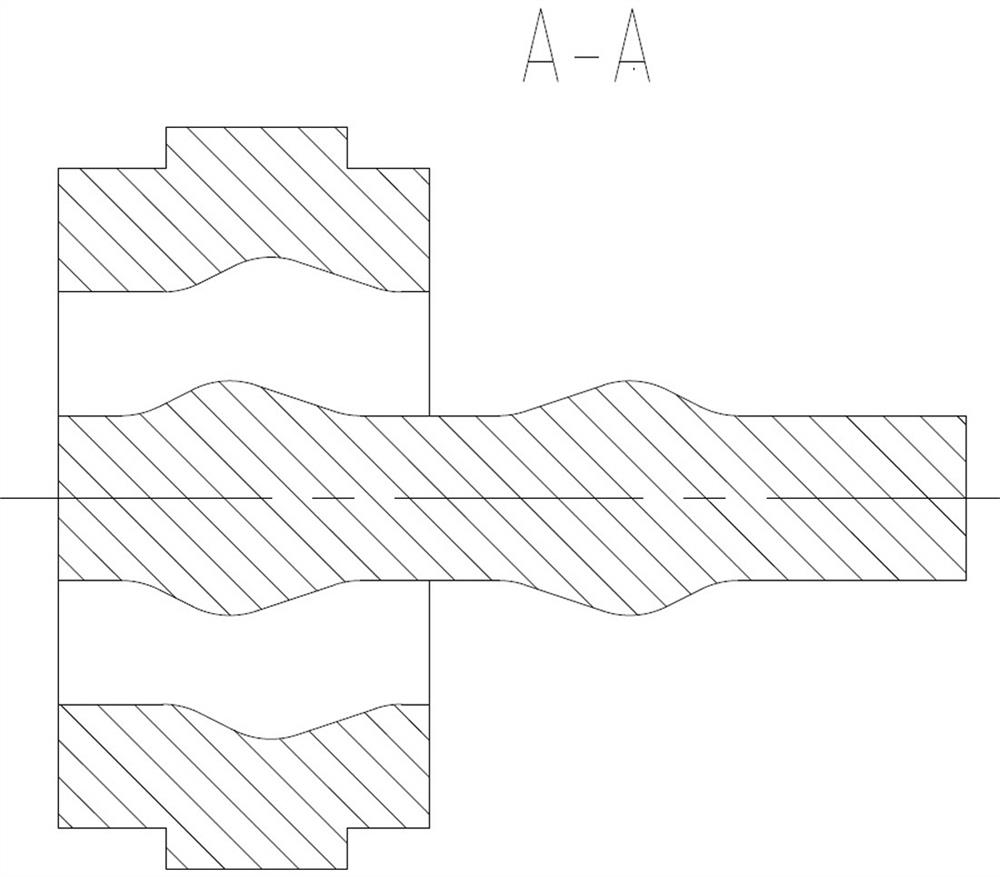

[0018] The present invention will be described below in conjunction with accompanying drawing, as figure 1 As shown, in the semi-solid magnesium alloy gradient extrusion composite die provided by the present invention, the left side of the support plate 1 is connected to the casting and rolling mill frame by bolts, and the right side of the support plate is connected with a shunt chamber 2 by interference fit. The shunt chamber 2 The right side is connected to the punch 4 through a clearance fit, the right side of the punch 4 is connected to the die 5 through a clearance fit, the right side of the die 5 is connected to the support 8 through bolts, and the right side of the support 8 is connected to the base 9; the support 8 and the support A control room 3 is arranged between the plates 1, and the control room 3 is annularly wrapped on the outside of the distribution chamber 2, the punch 4 and the die 5; The axis coincides; as Figure 2-6 As shown, the outer side of the mandr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com