Warm rolling processing method for controlling texture of titanium alloy seamless pipe and titanium alloy pipe

A technology for seamless pipes and processing methods, which is applied in metal processing equipment, manufacturing tools, temperature control, etc., can solve problems such as difficulty in obtaining high-ratio, high-strength radial textures, and achieve improved texture distribution, radial Effect of Texture Enhancement, High Strength and Fatigue Properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

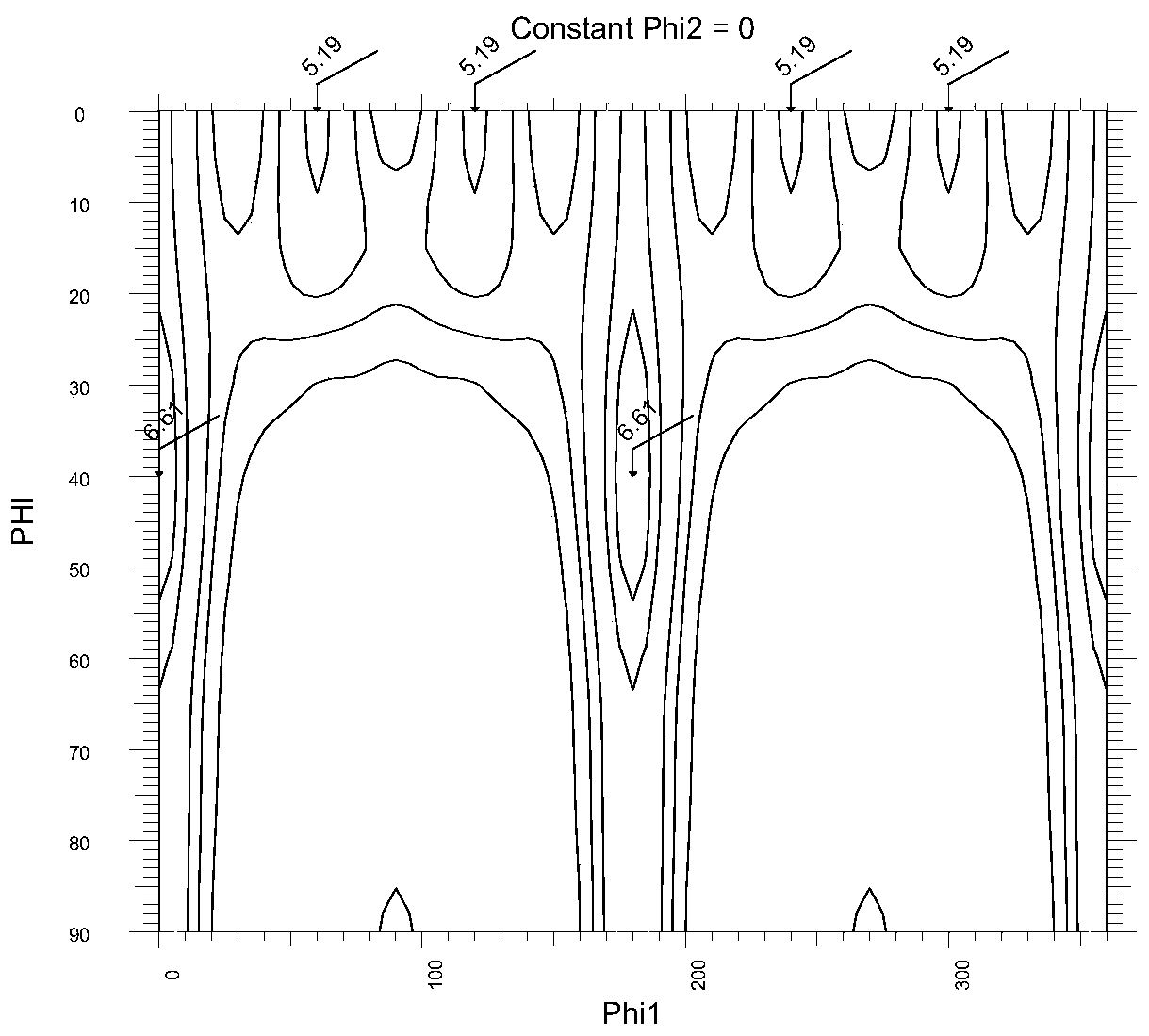

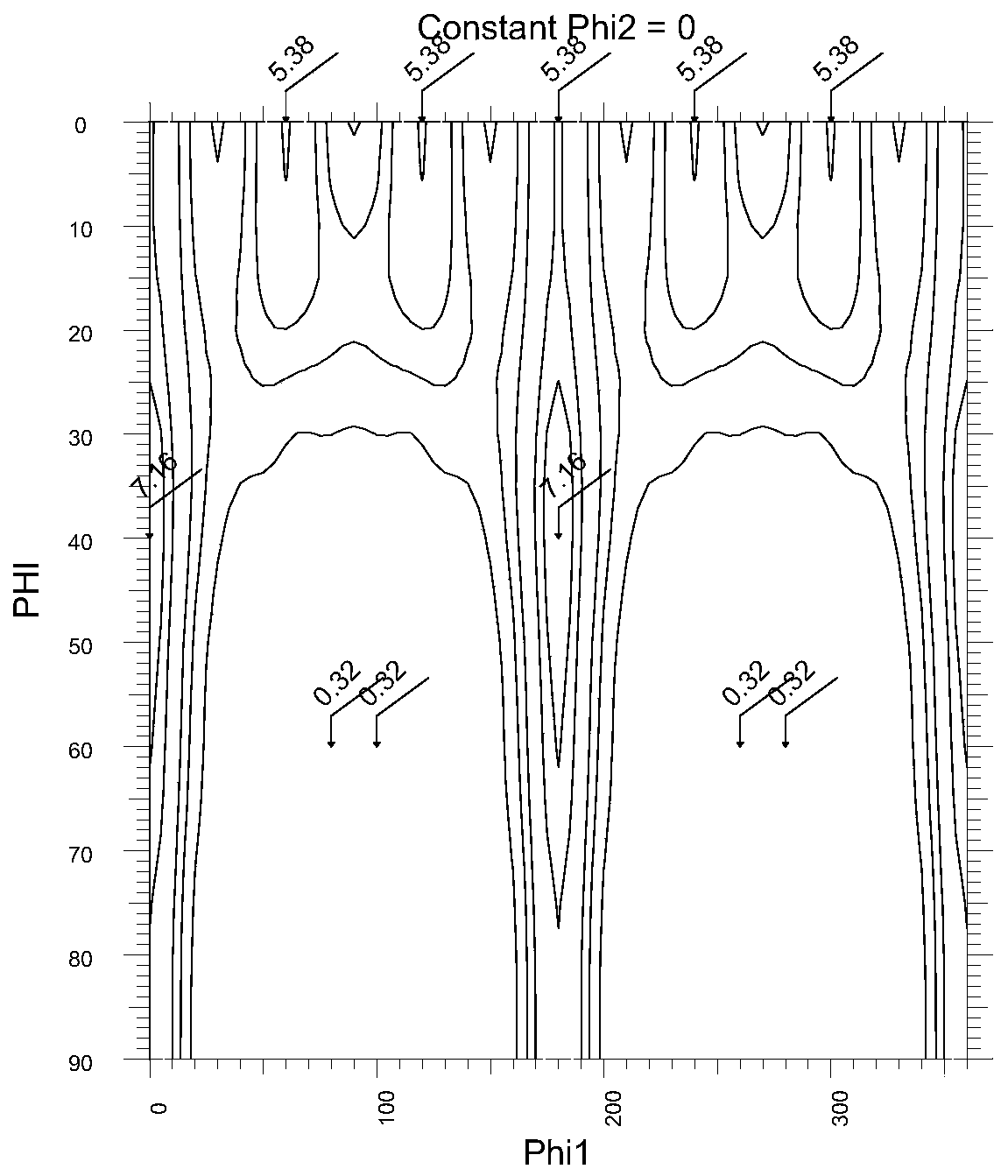

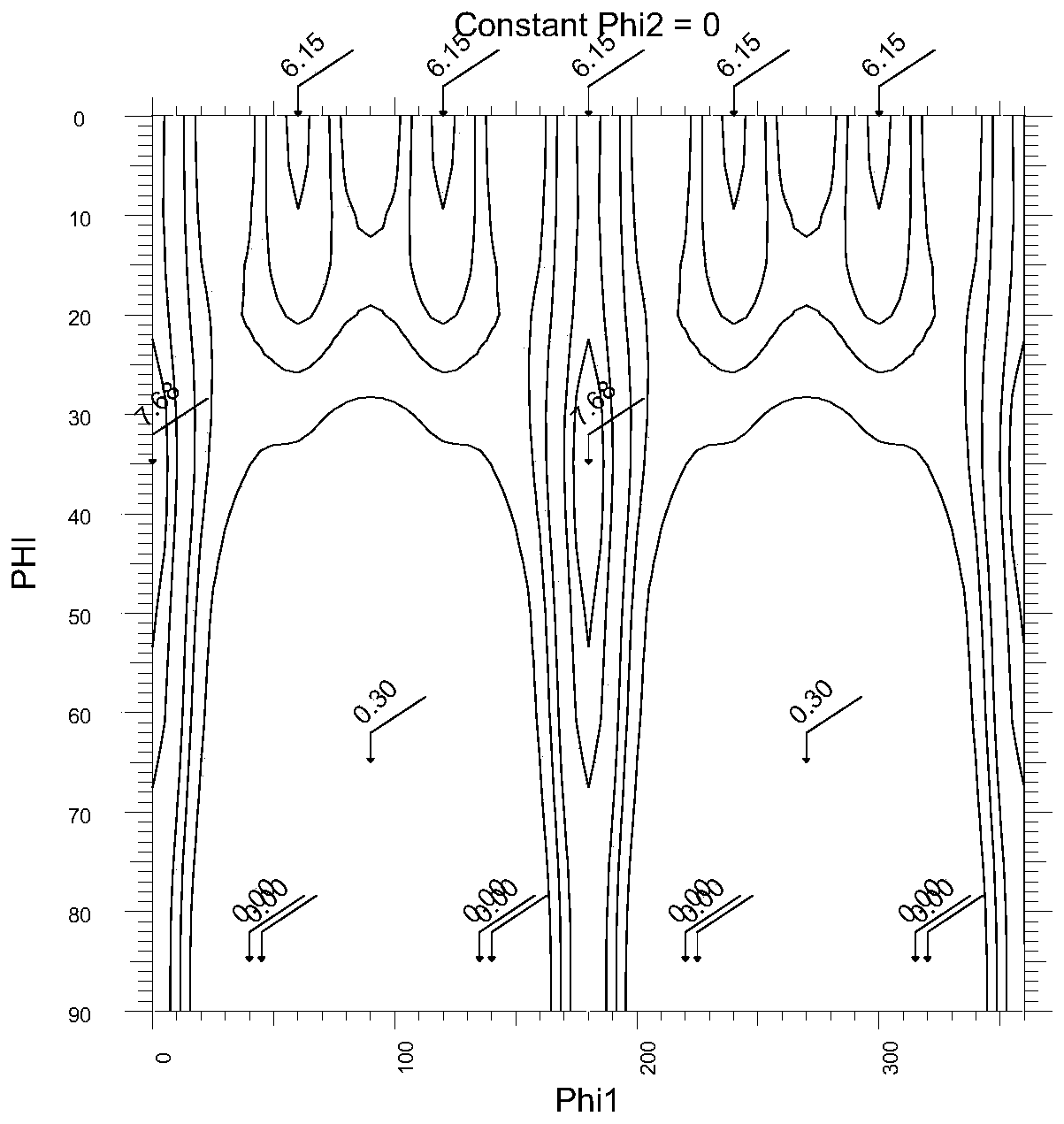

Image

Examples

Embodiment 1

[0037] This embodiment provides a titanium alloy pipe with a specification of TA18 with an outer diameter of φ6×wall thickness of 0.5mm, which is prepared by the following steps: tube blank: prepare a TA18 titanium rod with a diameter of φ100mm, cover it after drilling and drilling, and heat it On a 1600-ton extrusion machine, a φ39×6mm tube blank is extruded;

[0038] Warm rolling: heat the tube billet to 100°C in the induction coil, keep it warm for 15-30min, send it into the three-roller tube mill, carry out rolling deformation, and carry out 3-6 passes of warm rolling, and control the temperature of each pass. The rolling deformation rate is not less than 40% and not more than 55%; stress relief annealing: after warm rolling, the tube billet is sent to a vacuum heat treatment furnace, heated at 450°C, and the vacuum degree is less than 8×10 -2 Pa, time 24min;

[0039] Then pickling, cutting to length, and obtaining the titanium alloy pipe material of TA18 with the specifi...

Embodiment 2

[0041]The difference between this embodiment and embodiment 1 is that in the warm rolling step, the tube blank is heated to 200°C;

Embodiment 3

[0043] The difference between this embodiment and embodiment 1 is that in the warm rolling step, the tube blank is heated to 300°C;

[0044] Sampling is carried out for mechanical performance testing. The tensile strength of the stress-relieved annealed pipe after warm rolling is not less than 860MPa, and the plasticity is not less than 11%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| plasticity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com