Low-cost high-speed-extruded magnesium alloy material and preparation process thereof

A preparation process and technology of magnesium alloy, applied in the field of metal materials, can solve the problems of weak non-basal texture, high cost, low extrusion speed of extrusion materials, etc., and achieve improved room temperature plasticity, low cost and extrusion production efficiency. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

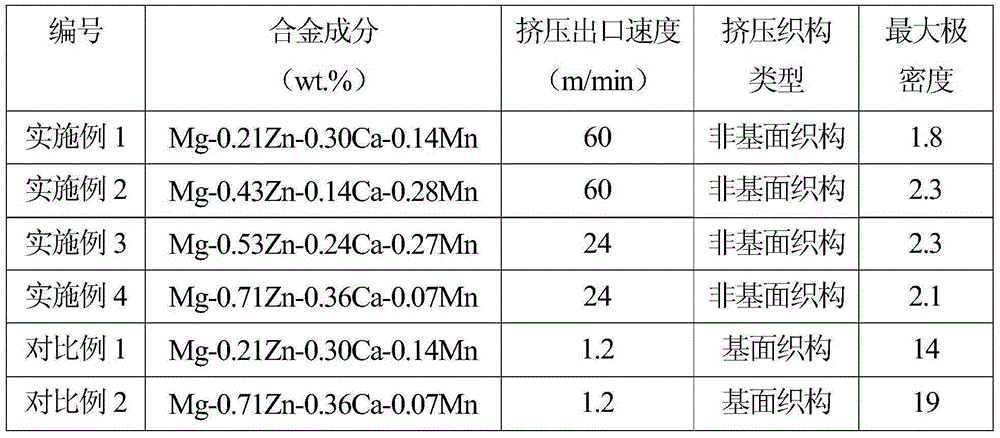

[0032] 1) Metal mold gravity casting is adopted, Mg-Zn-Ca-Mn is smelted and poured into an ingot of 80mm×180mm×200mm through conventional magnesium alloy melting, and the weight percentage of the alloy composition is Zn: 0.21%, Ca: 0.30%, Mn: 0.14 %, the magnesium content is the balance balance;

[0033] 2) Homogenize the ingot at 400°C for 10 hours, then heat it up to 450°C for 10 hours, then cut the homogenized ingot into corresponding extrusion billets;

[0034] 3) Heat the extrusion die to the extrusion deformation temperature of 400°C, then put the extrusion billet into the extrusion barrel and heat it for 8 minutes. After the extrusion billet reaches the deformation temperature of 400°C, it will be processed into a bar at high speed. 60m / min, the extrusion ratio is 20;

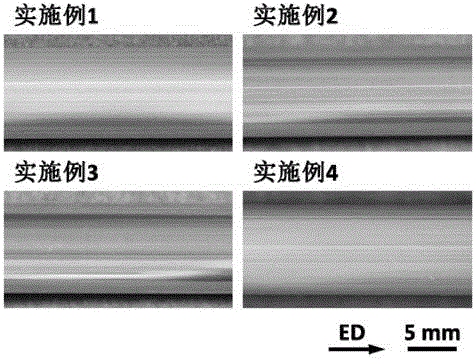

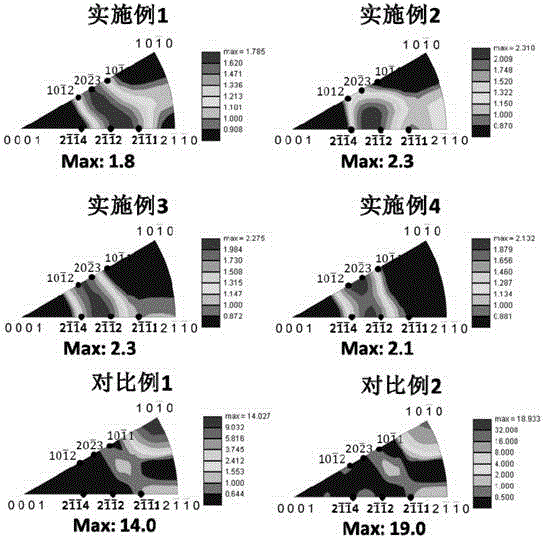

[0035] 4) The surface of the extruded material is smooth without any surface cracks, see figure 1 ; The texture of the extruded material is a weak non-basal texture, and the non-basal texture component...

Embodiment 2

[0037] 1) Metal mold gravity casting is adopted, Mg-Zn-Ca-Mn is smelted and poured into an ingot of 80mm×180mm×200mm through conventional magnesium alloy melting, and the weight percentage of the alloy composition is Zn: 0.43%, Ca: 0.14%, Mn: 0.28 %, the magnesium content is the balance balance;

[0038] 2) Homogenize the ingot at 380°C for 6 hours, then raise the temperature to 440°C for 4 hours, and then cut the homogenized ingot into corresponding extrusion billets;

[0039] 3) First heat the extrusion die to the extrusion deformation temperature of 300°C, then put the extrusion billet into the extrusion barrel and heat for 5 minutes, after the extrusion billet reaches the deformation temperature of 300°C, it is processed into a bar at high speed, and the extrusion exit The speed is 60m / min, and the extrusion ratio is 20;

[0040] 4) The surface of the extruded material is smooth without any surface cracks, see figure 1 ; The texture of the extruded material is weak non-b...

Embodiment 3

[0042] 1) Metal mold gravity casting is adopted, Mg-Zn-Ca-Mn is melted and poured into an ingot of 80mm×180mm×200mm by conventional magnesium alloy, and the weight percentage of the alloy composition is Zn: 0.53%, Ca: 0.24%, Mn: 0.27 %, the magnesium content is the balance balance;

[0043] 2) Homogenize the ingot at 400°C for 12 hours, then heat it up to 450°C for 12 hours, then cut the homogenized ingot into corresponding extrusion billets;

[0044] 3) First heat the extrusion die to the extrusion deformation temperature of 300°C, then put the extrusion billet into the extrusion barrel and heat for 5 minutes, after the extrusion billet reaches the deformation temperature of 300°C, it is processed into a bar at high speed, and the extrusion exit The speed is 24m / min, and the extrusion ratio is 20;

[0045] 4) The surface of the extruded material is smooth without any surface cracks, see figure 1 ; The texture of the extruded material is a weak non-basal texture, and the non...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com