Rare earth aluminum alloy with high thermal conductivity

An aluminum alloy, high thermal conductivity technology, applied in the field of metal alloys, can solve problems such as the lack of LED light source radiators, and achieve the effects of improving plastic forming performance and processing performance, strengthening the degree of alloying, and compacting the alloy structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

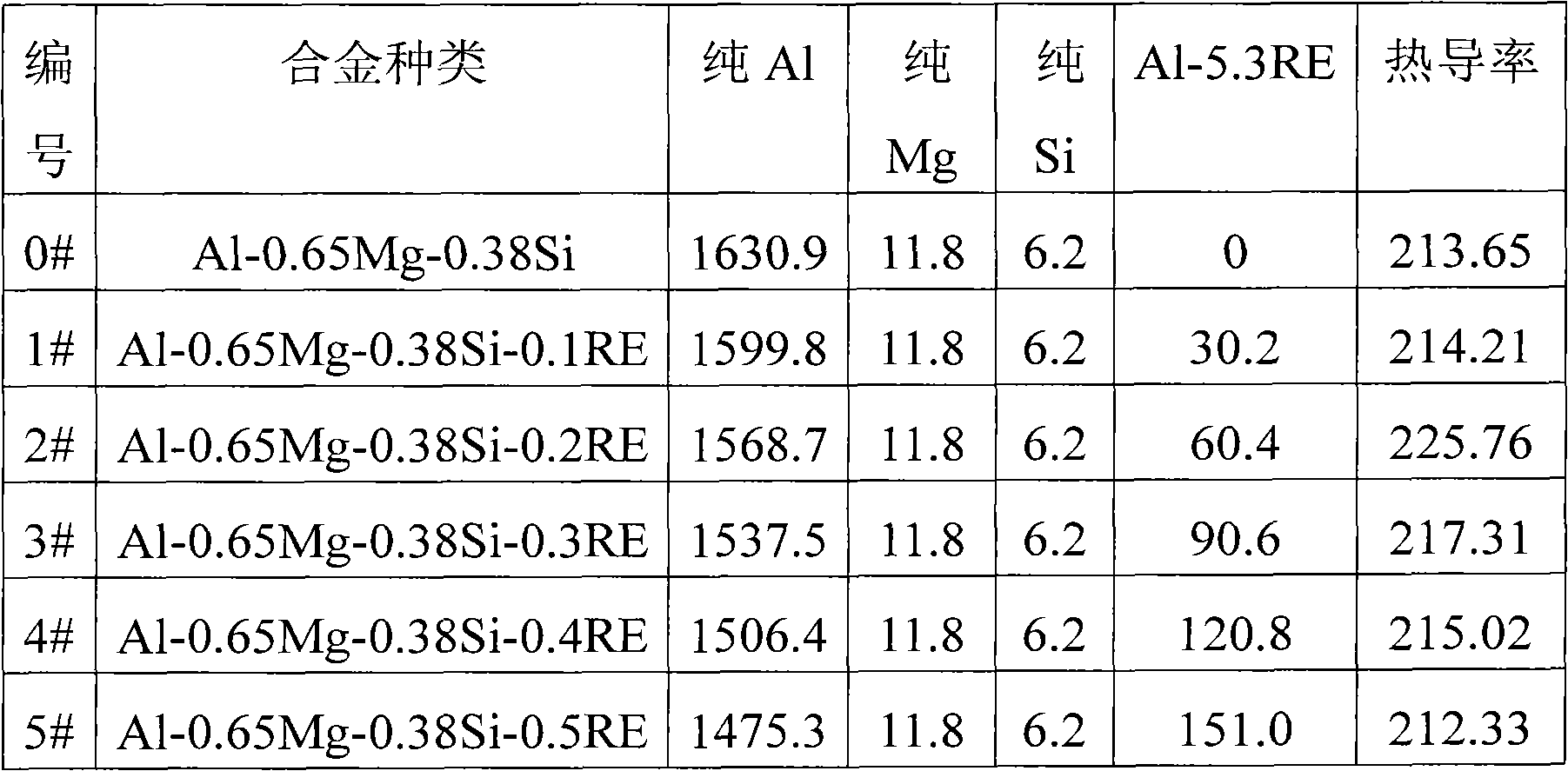

[0010] The present invention will be further described below in conjunction with the examples. The Al-Mg-Si-RE aluminum alloy is prepared by using the traditional aluminum alloy smelting process, which is divided into two steps: first, pure Al (purity reaches 99.99%) and mixed rare earth La-Y are used as raw materials , smelting and casting in a hollow induction furnace by the method of pair mixing, and preparing Al-5.3RE master alloy; The melting temperature is 750°C. After pure Al and pure Si in the state of fine powder are completely melted, add pure magnesium (purity reaches 99.99%) to the melt, stir well, and then add Al-5.3RE in the middle Alloy, stir evenly, feed N into the melt 2 -Cl 2 The mixed gas is refined and degassed, and the slag is removed, and finally the solution is injected into a volume of 100×90×36(mm 3 ) in a rectangular mold, cooling for 3 to 5 minutes to make Al-Mg-Si-RE rare earth aluminum alloy. Below is the comparison of the thermal conductivity o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com