Anti-oxidation metal product

A metal product, anti-oxidation technology, used in semiconductor/solid-state device manufacturing, electrical components, electrical solid-state devices, etc. The effect of solving the problem of copper wire oxidation, low pinhole rate and excellent conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

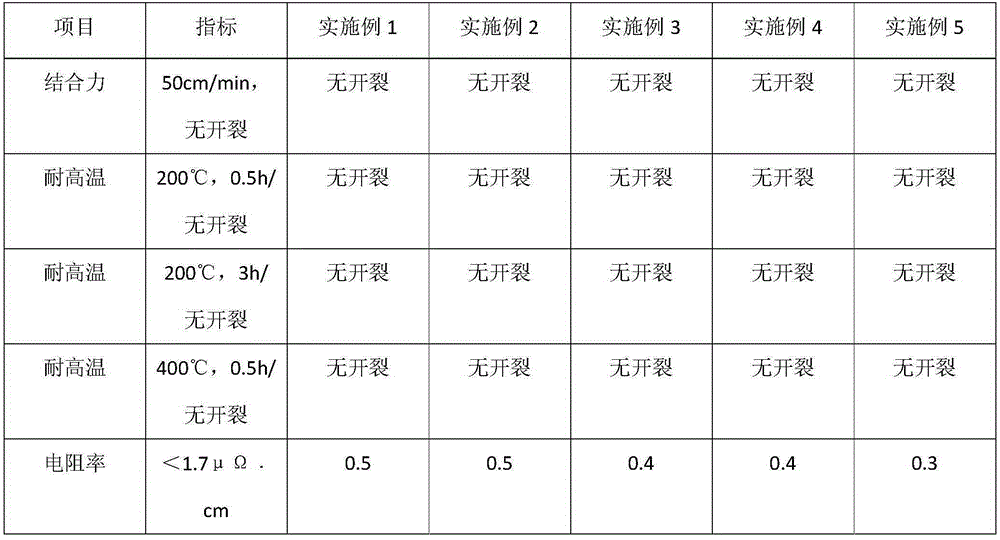

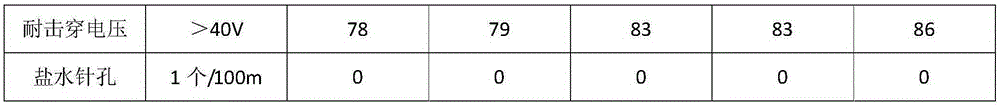

Embodiment 1

[0021] An anti-oxidation metal product of the present invention, the anti-oxidation metal product is a bonded copper wire, the purity of the copper wire is ≥99.99wt%, its surface is coated with an anti-oxidation layer with a thickness of 1nm, and the anti-oxidation layer is composed of the following parts by weight The components consist of: fullerene 0.1kg, aluminum 2kg, polyethylene 8kg, polyacrylamide 11kg, carbon disulfide 1kg.

[0022] The preparation method of the anti-oxidation metal product:

[0023] (1) Put high-purity copper with a purity of 99.999wt% into an intermediate frequency induction furnace for smelting to turn it into copper liquid, then pour it into a graphite ingot mold, keep the vacuum, and turn on the gas injection after the furnace is completely cooled down valve, and open the furnace cover, cool the formed ingot with pure water, and then dry it with compressed air;

[0024] (2) Use vertical smelting to further smelt it, then put it into a crucible, s...

Embodiment 2

[0030] An anti-oxidation metal product of the present invention, the anti-oxidation metal product is a bonded copper wire, the purity of the copper wire is ≥99.99wt%, its surface is coated with an anti-oxidation layer with a thickness of 2nm, and the anti-oxidation layer is composed of the following parts by weight The components consist of: fullerene 0.5kg, aluminum 8kg, polyethylene 15kg, polyacrylamide 16kg, carbon disulfide 3kg.

[0031] The preparation method of the anti-oxidation metal product:

[0032] (1) Put high-purity copper with a purity of 99.999wt% into an intermediate frequency induction furnace for smelting to turn it into copper liquid, then pour it into a graphite ingot mold, keep the vacuum, and turn on the gas injection after the furnace is completely cooled down valve, and open the furnace cover, cool the formed ingot with pure water, and then dry it with compressed air;

[0033] (2) Use vertical smelting to further smelt it, then put it into a crucible, ...

Embodiment 3

[0039] An anti-oxidation metal product of the present invention, the anti-oxidation metal product is a bonded copper wire, the purity of the copper wire is ≥99.99wt%, its surface is coated with an anti-oxidation layer with a thickness of 1.5nm, and the anti-oxidation layer is composed of the following weight Parts are composed of: fullerene 0.4kg, aluminum 3kg, polyethylene 9kg, polyacrylamide 12kg, carbon disulfide 2kg.

[0040] The preparation method of the anti-oxidation metal product:

[0041] (1) Put high-purity copper with a purity of 99.999wt% into an intermediate frequency induction furnace for smelting to turn it into copper liquid, then pour it into a graphite ingot mold, keep the vacuum, and turn on the gas injection after the furnace is completely cooled down valve, and open the furnace cover, cool the formed ingot with pure water, and then dry it with compressed air;

[0042] (2) Use vertical smelting to further smelt it, then put it into a crucible, seal it, tur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com