Multi-ram die forging process method and die for 40Cr-steel frame type parts

A multi-directional die forging and machine body technology, which is used in the manufacture of tools, metal processing equipment, forging/pressing/hammer devices, etc., can solve the problems that productivity needs to be improved, cannot be formed in one step, etc., and achieves improved service life and plastic forming. The effect of improving performance and improving plastic formability

Inactive Publication Date: 2012-11-14

CHONGQING UNIV OF TECH

View PDF7 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Jia Jianlei, Li Ping, Xue Kemin, etc. "Hot Extrusion Process Analysis and Die Design of Body Seat" (see Metal Processing, 2009 (19), pp. 60-61) proposed the technology of processing 30CrMnMoTiA body seat forgings by hot extrusion process Plan, designed the process plan including billet making, flattening and hot extrusion forming, and the hot extrusion die with divisible die structure, and determined the process plan of one mold with two parts through force analysis; its advantage is that it solves the problem of partial load It also reduces the man-hours of subsequent machining, improves the utilization rate of materials, and reduces the production cost. However, because the billet still needs to be flattened first, it cannot be formed in one step, so the productivity still needs to be improved.

Xia Juchen, Hu Guoan, etc. have studied the multi-directional die forging die and multi-directional die forging process of 7A04 aluminum alloy casing parts (see Chinese patent documents CN 101214526 and CN 201217051Y), etc., but no one has adopted multi-directional die forging Research on Multidirectional Die Forging of 40Cr Steel Airframe Seats

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

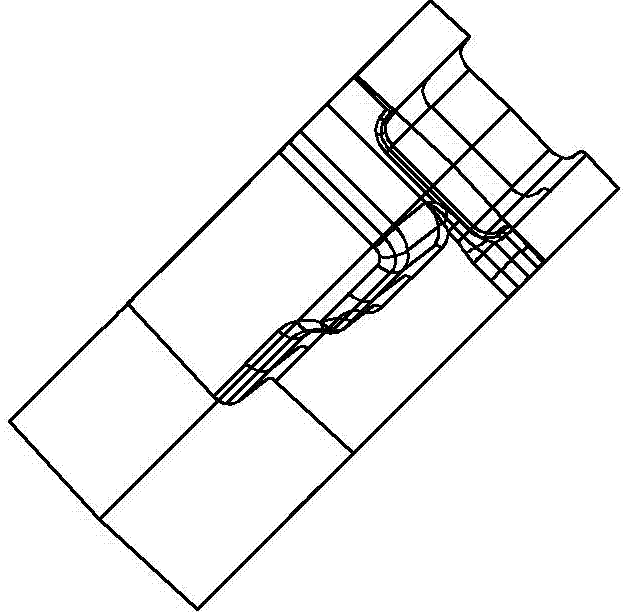

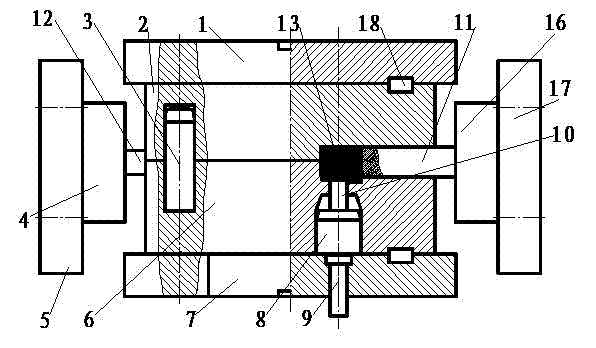

The invention discloses a multi-ram die forging process and a die for 40Cr-steel frame type parts, belongs to the technical field of plastic forming for a metal material, and aims at effectively avoiding the problems in an existing open die forging process and a existing isothermal forging process. The multi-ram die forging process comprises the steps of blanking, heating and multi-ram die forging, wherein, the multi-ram die forging comprises the steps as follows: (1) stocks are heated until the temperature reaches 1000 to 1180 DEG C through intermediate frequency induction; and (2) heated blanks are formed in one step through a multi-ram die forging die. The multi-ram die forging die comprises symmetrical left and right lateral male dies, an upper half male die, a lower half male die, a lateral male die fixing board and a die frame, wherein, the die frame comprises an upper die holder and a lower die holder. The invention has the advantages as follows: the technological process is reasonable, and the processing parameter and the performance are stable; the structure of the die is simple, the die is convenient to manufacture, install and use, and the operation is reliable; the friction resistance between forged pieces and a die cavity can be reduced greatly, the service life of the die is prolonged obviously, the surface quality of the forged pieces can be improved, and the utilization ratio of materials is high; and one-step forming can be achieved, and pre-forging is not required.

Description

technical field [0001] The invention relates to a die forging process and a mold for mechanical parts, in particular to a multi-directional die forging production process and a die for producing 40Cr steel machine body seat parts, and belongs to the technical field of plastic forming of metal materials. Background technique [0002] 40Cr steel is a low hardenability quenched and tempered steel, and it is also the most widely used alloy quenched and tempered steel in China, but the machining performance of 40Cr steel is not very good. At present, the domestic military industry system for 40Cr steel casing body parts, the traditional method is to adopt the open die forging process of die forging hammer, and the process flow is blanking→heating→forging→trimming. The main problems in the process are that the flash is too thick, the metal loss is large, the tolerance of the forging is large, the subsequent machining allowance is large, and the utilization rate of the material is...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): B21J5/02B21J13/02B21J13/14

Inventor 周志明唐丽文罗荣范青松胡治姚照云曹敏敏胡洋

Owner CHONGQING UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com