Precision die forging and shaping technical method for automobile steering knuckle rough type parts

A technology for automobile steering knuckle and precision die forging, which is applied in vehicle parts, railway car body parts, metal processing equipment, etc., to achieve the effects of small forging allowance and tolerance, reasonable technological process, and reduced contact friction resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Example 1: 6700 Steering Knuckle Blank Precision Forging Process

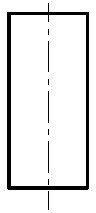

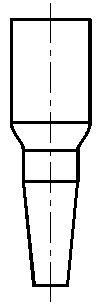

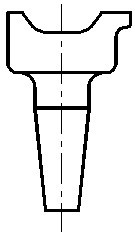

[0038]After structural optimization, the precision forging process of 6700 steering knuckle blank is shown in Figure 1. Firstly, the 40Cr round steel with a diameter of 80 mm is cut by a band saw machine, and cut into a round bar with a length of 182 ± 2 mm as shown in Figure 1 (a). Then use a medium frequency induction heating furnace to heat the round bar to 1150±10°C. Put the heated round bar into the extrusion die. The diameter of the big end of the die is φ81mm, which is 1mm larger than the diameter of the bar, which is convenient for placing the bar. The diameter of the punch is the same as the diameter of the bar is φ80mm , the lower end of the die is the same as the optimized shape of the stem of the steering knuckle blank, and the bottom of the mold has a jacking device with the same diameter as the bottom end of the stem of the steering knuckle blank. After extrusion and elongation, a blank c...

Embodiment 2

[0039] Example 2: EQ153 Steering Knuckle Blank Precision Forging Process

[0040] After structural optimization, the precision forging process of the EQ153 steering knuckle blank is shown in Figure 3. First, use a band saw to cut 40Cr round steel with a diameter of 130 mm, and cut it into a round bar with a length of 185 ± 2 mm as shown in Figure 3 (a). Then use a medium frequency induction heating furnace to heat the round bar to 1160±10°C. Put the heated round bar into the extrusion die. The diameter of the big end of the die is φ132mm, which is 2mm larger than the diameter of the bar, which is convenient for placing the bar. The diameter of the punch is the same as the diameter of the bar is φ130mm , the lower end of the die is the same as the optimized shape of the stem of the steering knuckle blank, and the bottom of the mold has a jacking device with the same diameter as the bottom end of the stem of the steering knuckle blank. After extrusion and elongation, a blank c...

Embodiment 3

[0041] Example 3: SK1 Steering Knuckle Blank Precision Forging Process

[0042] After structural optimization, the precision forging process of SK1 steering knuckle blank is shown in Figure 5. The forging process is the same as the precision forging process of the 6700 steering knuckle blank in Example 1, except that the diameter and length of the raw material of the 40Cr round bar are different. The forged shape is different. In the process of multi-directional die forging, the plane shown by the arrow G shown in Figure 5(d) is used as the horizontal parting surface of the upper and lower dies, as shown in Figure 6 The parts where the middle arrows H and I are located and the parts where the arrows J and K are located are front and rear symmetrical in the middle as the vertical parting surface. Compared with the traditional upper and lower die forging SK1 steering knuckle blanks, the SK1 steering knuckle obtained by this precision die forging process has been optimized and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com