Two-way hydroforming mold for microtubes

A two-way hydraulic and forming mold technology, which is applied in the field of micro-tube forming, to achieve the effects of avoiding communication, improving plastic forming ability, and improving sealing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

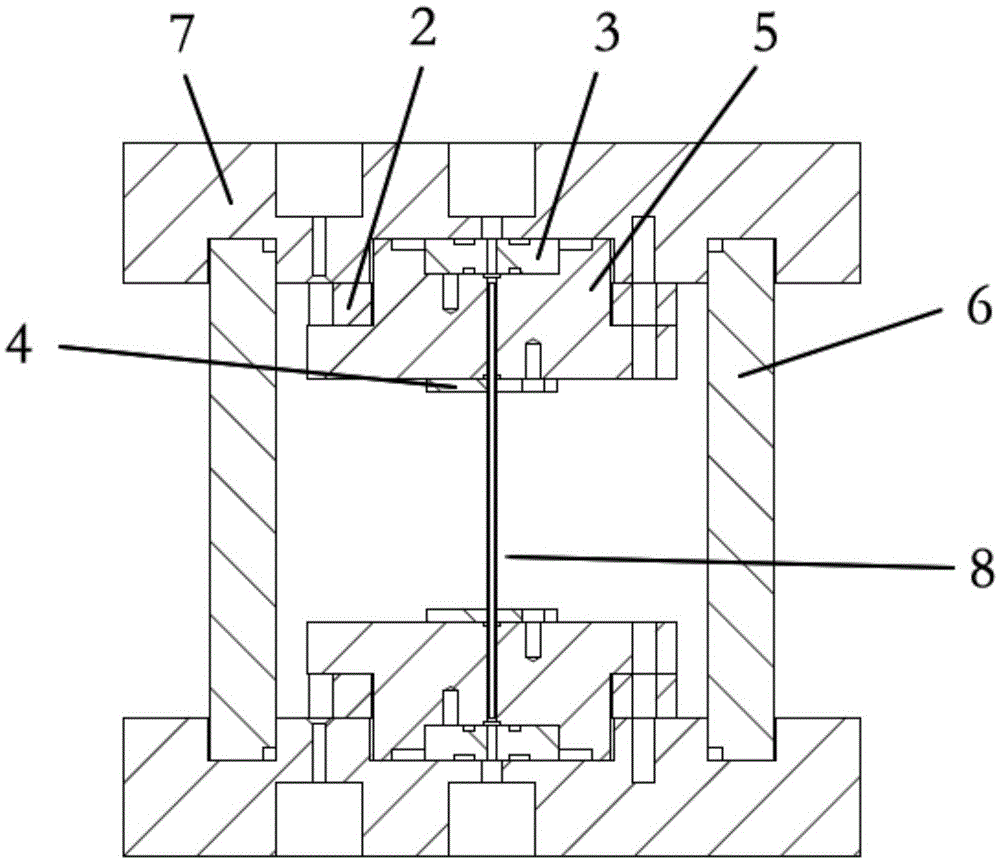

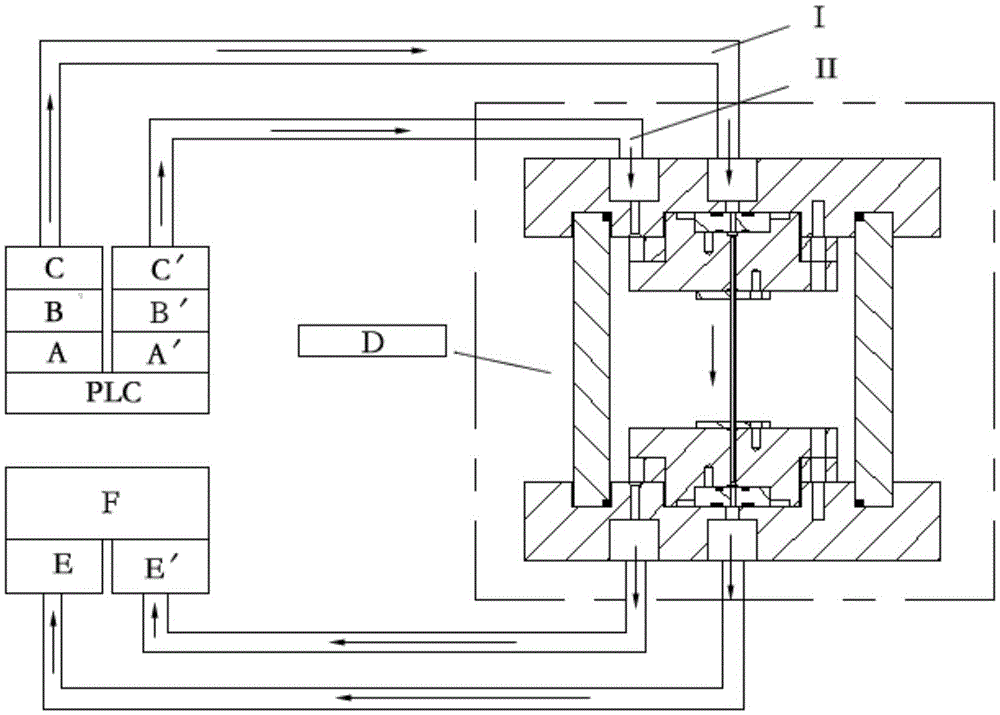

[0020]A molding device using the micro-tube bidirectional hydraulic molding die of the present invention includes a PLC control module, an internal pressure pump A, an external pressure pump A', an internal pressure supercharger B, an external pressure supercharger B', an internal pressure Pressure check valve C, external pressure check valve C', internal pressure high pressure needle valve E, external pressure high pressure needle valve E', fuel tank F forming die D; wherein, the forming die includes a guide block 7, a cylindrical shell 6, an insert Block 5, blank holder 4, sealing block 3 and gasket 2; there are two holes on one end of the guide block 7, one of which is the internal pressure liquid port of the micro-tube located at the center of the guide block 7, and the other hole is located at the center of the guide block 7. The external pressure liquid port of the microtube at the eccentric position of the guide block 7, the other end face of the guide block 7 has an ann...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com